- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Online Producer Gas Monitoring System

Price 768500 INR/ Piece

Online Producer Gas Monitoring System Specification

- Operate Method

- Semi Automatic

- Display Type

- LED

- Hardness

- Yes

- Product Type

- Gas Monitoring System

- Operating Voltage

- 110-215 Volt (V)

- Power Supply

- Manual

- Usage

- Industrial

Online Producer Gas Monitoring System Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 20 Pieces Per Week

- Delivery Time

- Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, Himachal Pradesh, Assam, Madhya Pradesh, Pondicherry, Meghalaya, Gujarat, Maharashtra, West India, North India, Chhattisgarh, Andhra Pradesh, East India, West Bengal, Nagaland, Mizoram, Odisha, Delhi, Andaman and Nicobar Islands, Karnataka, Daman and Diu, Telangana, Kerala, Tamil Nadu, Uttarakhand, Dadra and Nagar Haveli, Uttar Pradesh, Punjab, Tripura, Rajasthan, Jammu and Kashmir, Chandigarh, South India, Manipur, Arunachal Pradesh, Sikkim, Haryana, Lakshadweep, Bihar, Jharkhand, Central India, Goa

About Online Producer Gas Monitoring System

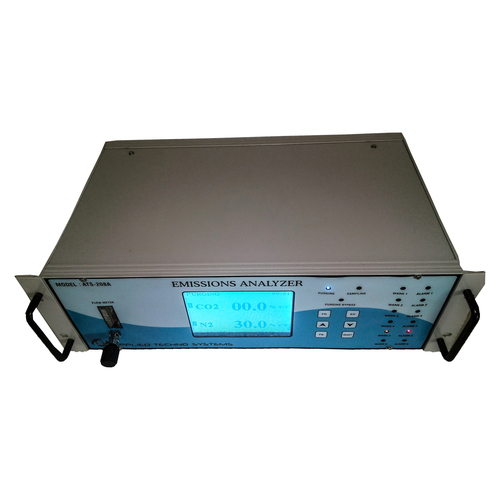

Producer Gas Monitoring System Model ATS-208A

Basically, gasification is a process where a fuel or feedstock is cooked in low oxygen conditions. The equipment that carries out this whole process is usually called a gasifier.Different zones inside the gasifier support drying, pyrolysis, combustion, and reduction reactions. The whole process produces gas that contains primarily carbon monoxide and hydrogen. These gases can be carried away before they combust, and then used elsewhere for energy. The gas is often called synthesis gas or syngas for short. It has also been referred to in the past as producer gas or town gas.Applied Model ATS 204A Producer Gas Analyzer has been designed considering the flexibility required in the environments that characterize syn gas and bio-mass applications.The analyzer uses high-stability infrared sensors for the simultaneous measurement of CO, CO2 and CH4 . In addition, the analyzer can also be supplied with a non-consumable, long-life thermal conductivity cell for H2 that compensates for the interference effects of CO, CO2 and CH4 . This ensures that H2 will always read 2correctly regardless of the background gas composition. Paramagnetic sensor can be used for O2 analysis as an option.All sensors are temperature-compensated for maximum analytical stability.

Applied Techno Systems Advantages

- Ensured after sales & service support

- Spares and accessories availability guaranteed

- Low cost of ownership, maintenance and installation

- Combination of technologies and integration under one roof

Specification :-

| Principle | NDIR for CO,CO2,CH4, |

| | Electrochemical sensor for O2 (Paramagnetic sensor as option) |

| | Thermal conductivity cell for H2 |

| Ranges Available | O2 0-25.0%, 0-50.0%, 0-100.0% |

| | H2 0-5.0%, 0-50.0%, 0-100.0% |

| | CO 0-10.0%, 0-50.0%, 0-100.0% |

| | CO2 0-10.0%, 0-50.0%, 0-100.0% |

| | CH4 0-50.0%, 0-100.0% |

| Resolution | 0.01% for all gases |

| Power Source | 230VAC 50hz |

| Accuracy & Repeatability | 1% of reading for all gases |

| Response Time (T-90) | 20-30 seconds to 90% step change |

| Drift | Less than 2% of full scale per month |

| Computer Interface | RS 232, USB, RS485 |

| Sensor Life | 2-3 Years |

| Environmental | |

| Ambient Temperature Range | -5 to 55 C |

| Relay Output | Potential free contacts |

| Operating Gas Temperature | 0-600 C |

| Dimension in mm | 430 (W) X 150(H) X 250(D) |

| Weight | 2.5 KG |

| Warranty | One Year |

Reliable Gas Monitoring for Industries

The system enables seamless and accurate producer gas analysis, supporting industrial operators with reliable, continuous data. Its robust construction is confirmed by high hardness standards, and the LED display guarantees clear visualization for rapid decision-making. Suited for facilities across India, the product helps maintain operational integrity and safety.

Flexible Operation and Power Options

With a semi-automatic operation method, this monitoring system allows users to adjust settings as needed while maintaining efficiency. Powered manually and compatible with a wide voltage range, it can be easily integrated into varied industrial infrastructures, making it suitable for exporters, importers, manufacturers, and service providers alike.

FAQs of Online Producer Gas Monitoring System:

Q: How does the Online Producer Gas Monitoring System operate in industrial settings?

A: The system uses a semi-automatic method, requiring manual power input and user interaction for certain functions, while continuously monitoring producer gas parameters through its LED display.Q: What are the benefits of continuously monitoring producer gas in factories?

A: Continuous monitoring ensures consistent gas quality, aids in early detection of irregularities, enhances operational safety, and supports regulatory compliance for industrial processes.Q: When should the Online Producer Gas Monitoring System be utilized?

A: It should be employed during all producer gas generating operations in industrial environments where uninterrupted analysis and data accuracy are mandatory to ensure safety and efficiency.Q: Where can businesses procure the Online Producer Gas Monitoring System in India?

A: Businesses can obtain this system from a range of sources across India, including exporters, importers, manufacturers, service providers, and suppliers specializing in industrial gas monitoring solutions.Q: What is the process for installing and using this monitoring system?

A: Installation typically involves configuring the device for the appropriate voltage supply (110-215V), setting up the LED display, and calibrating the device as per specific industrial requirements. Operation involves manual power supply and periodic adjustments as needed.Q: How is the producer gas data displayed to the operator?

A: The system is equipped with a clear LED display that provides real-time producer gas readings, allowing operators to monitor levels and composition efficiently during operation.Q: What features ensure the durability of the Online Producer Gas Monitoring System?

A: Designed with high hardness and robust build quality, the system is engineered to withstand industrial conditions and maintain accurate functioning under continuous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry