- Dew Point Meters

- Gas Analysers

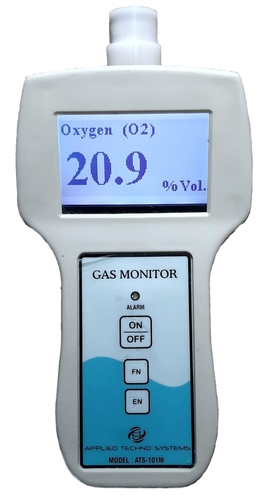

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Combustible Gas Sensor Transmitter

Price 19500 INR/ Unit

Combustible Gas Sensor Transmitter Specification

- Voltage

- 24 Volt (v)

- Usage

- Detection of gases

- Operate Method

- Continue

- Humidity

- 95

- Temperature

- -5 to 55 Celsius (oC)

- Weight

- 0.300 Kilograms (kg)

- Application

- Detection of combustible/Toxic gases

- Power

- 24 Volt (v)

- Power Supply

- 24 V DC

- Product Type

- Detector

- Machine Weight

- 0.300 Kilograms (kg)

- Control Mode

- sampling Diffusion

Combustible Gas Sensor Transmitter Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 200 Units Per Month

- Delivery Time

- 1-2 Week

- Packaging Details

- Normal packing with thermocol

- Main Export Market(s)

- Western Europe, Australia, Central America, Africa, Eastern Europe, Middle East, South America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- NO

About Combustible Gas Sensor Transmitter

Combustible Gas Sensor Transmitter

The Model ATS-109TD incorporates a pellistor or catalytic bead sensor. This sensor consists of a matched pair of elements, one active and the other for compensation. When in contact with a combustible hydrocarbon or solvent causes the gas or vapor to "burn" or oxidize at concentrations below the Lower Explosive Limit (LEL). This oxidization process raises the temperature of the active bead and increases the resistance of the internal wire coil. The second bead does not have the catalytic coating and provides compensation for environmental conditions including temperature and humidity. When these elements are connected to the circuit, a useable signal is produced that is proportional to the gas concentration.

Applications

- Environmental Monitoring

- Area Monitoring

- Pulp & Paper

- Leak Detection & Monitoring

- Chemical Plants

- Refineries/Petrochemical

- Hazardous Area

- Water/West water Treatment

- Fire Services

- Mines

Features

- Detection of combustible, toxic Gases and Oxygen

- Non-intrusive calibration

- Smart sensors

- Programmable relays

- 2-wire, 3-wire, ModBus

- Flame proof Junction Box

- Available in stainless steel

- Available in wireless version

- Flame proof Junction Box Approval CCOE & CMRI

Efficient Gas Detection for Enhanced Safety

Equipped to detect both combustible and toxic gases, this sensor transmitter provides fast, accurate alerts in potentially hazardous settings. Its continuous operation ensures uninterrupted monitoring, making it ideal for factories, refineries, and other industrial spaces concerned with workplace safety.

Robust Construction and Reliable Operation

Built to function in varying temperatures and high humidity, the sensor transmitter maintains performance in demanding industrial conditions. At just 0.300 kg, it is lightweight yet durable, enabling easy installation and integration into existing gas detection systems.

FAQs of Combustible Gas Sensor Transmitter:

Q: How does the Combustible Gas Sensor Transmitter detect gases?

A: This sensor utilizes sampling diffusion to continuously monitor and identify the presence of combustible and toxic gases in the environment, triggering alerts when unsafe levels are detected.Q: What types of gases can this transmitter detect?

A: The unit is suitable for detecting a broad range of combustible and toxic gases, making it ideal for a variety of industrial and safety-sensitive applications.Q: When should this gas sensor transmitter be installed?

A: Installation is recommended during initial setup of gas monitoring systems in industrial facilities, or when enhancing safety protocols in environments with potential gas hazards.Q: Where can the sensor transmitter be used?

A: This sensor is designed for use in industrial environments, such as factories, chemical plants, refineries, and spaces where monitoring of hazardous gases is critical.Q: What is the process for operating the sensor transmitter?

A: After installation and connection to a 24 V DC power supply, the device operates continuously, automatically detecting gas concentrations and alerting users when thresholds are surpassed.Q: What are the main benefits of using this gas sensor transmitter?

A: Key benefits include improved workplace safety, early leak detection, continuous monitoring, suitability for harsh environments, and lightweight design for easy handling.Q: How is the device powered and what are its operating conditions?

A: The sensor transmitter runs on a 24 Volt DC power supply and performs effectively within a temperature range of -5C to 55C and up to 95% humidity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Detector Category

CO Gas Transmitter

Price 26500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Continuous CO monitoring

Features : High sensitivity, Realtime monitoring, Long service life, Fault detection

Power Supply : 24V DC

High-Range Multi Gas Detector

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Features : High Quality

Power Supply : Electric

Material : ABS plastic

Portable Confined Space Gas Monitor

Price 32000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Features : High Quality

Power Supply : Electric

Material : ABS Plastic

Portable LPG Gas Leak Detector

Price 20000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Features : High Quality

Power Supply : Electric

Material : ABS Plastic

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese