- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Exhaust Gas Analyzer

Exhaust Gas Analyzer Specification

- Power Supply

- 100-240 VAC / 50Hz

- Material

- Mild Steel

- Humidity

- < 85%RH

- Temperature

- 15 Celsius (oC)

- Usage

- Industrial

- Capacity

- na

- Machine Weight

- 3 Kilograms (kg)

Exhaust Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Pack

- FOB Port

- Mumbai

- Supply Ability

- 20 Packs Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Exhaust Gas Analyzer

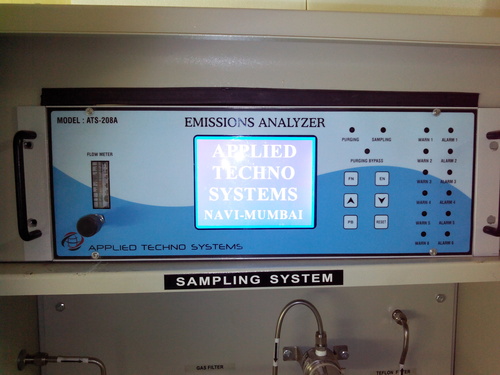

Exhaust Gas Analyzer: ATS-208A

Microcontroller regulated Exhaust Gas Analyzer uses built in pump for mechanical suctioning of exhaust gases. It supports RS-232 and RS-485 working interfaces and its highly sensitive sensor remains functional for up to 3 years. Impact protected ABS or PP housing of this instrument is highly durable. Provided Exhaust Gas Analyzer weighs 2.5 kg and its service life is 12 months.

Features:

- Microcontroller based intelligent instruments

- Continuous Monitoring of CO2 ,CH4, CO, O2,

- SO2,HF, NOX (NO+NO2), H2, H2S, N2

- Duel wavelength Infra red sensor

- Long Life Electrochemical sensor

- Six Gas Analysis in Single Analyser

- Single 320 X 240 Graphics LCD Display

- Self diagnostic & Self integrity check

- RS 232/RS 485 and USB Computer Interface

- Analog 4-20mA output for each gas

Technical Specifications

| Principle | Electrochemical, TCD, NDIR, Zirconium & Paramagnetic |

| Range | %V/V, % LEL, PPM, Mg/M3 |

| Resolution | 0.1 Unit or 1 Unit (Application based) |

| Sampling Method | Auto Suction though inbuilt Pump |

| Alarm | Relay Contact NO+NC |

| Display | 320 x 264 Graphics LCD |

| Sampling Condition | Temp:0-50 Deg. C |

| Pressure: | Less Than 1.5Kg/cm |

| Inbuilt Sampling System |

|

| Power Source | 100-240VAC/50Hz |

| Accuracy | +/2% |

| Response Time | <5 Second |

| Housing | High Impact Plastic |

| Sensor Life | 2-3 Years |

| Digital Output | RS-485,RS-232,USB |

| Analog Output | 4-20MA |

| Dimension in mm | 430(W) X 150(H) X 250(D)mm. |

| Weight | 2.5 KG |

| Warranty | One Year |

Efficient Exhaust Gas Monitoring

This analyzer provides accurate and real-time analysis of exhaust gases, making it ideal for industrial settings where emission control is crucial. Its compact design and lightweight build allow for easy installation and transport, while the robust mild steel construction ensures longevity even in demanding conditions. Use this device for regular environmental compliance checks and workplace air quality assessments.

Reliable Performance in Variable Conditions

Designed to operate smoothly within a temperature of 15C and in humidity levels below 85% RH, the analyzer delivers consistent results regardless of fluctuating environmental factors. The versatile power supply means it can be deployed in various industrial facilities throughout India, and its user-friendly controls simplify the monitoring process for staff at all expertise levels.

FAQs of Exhaust Gas Analyzer:

Q: How does the Exhaust Gas Analyzer function in industrial environments?

A: The analyzer continuously monitors and measures the concentrations of exhaust gases, providing real-time data that support emission control strategies for industrial facilities. Its mild steel build ensures durability against heavy usage over time.Q: What are the benefits of using this analyzer for exhaust gas monitoring?

A: The primary benefits include improved compliance with local emission standards, enhanced workplace safety, and reliable, accurate readings for maintenance and reporting purposes. Its lightweight construction also makes it easy to handle and position as needed.Q: When should exhaust gas monitoring be carried out in an industrial setting?

A: Routine monitoring is recommended during machinery operation, after maintenance, or whenever emission readings are required for regulatory reporting, ensuring safe environmental conditions and compliance.Q: Where can this Exhaust Gas Analyzer be installed?

A: It can be installed in industrial plants, manufacturing units, service centers, and other facilities involved in exhaust gas management throughout India, given its compact size and adaptable power requirements.Q: What is the process for operating the Exhaust Gas Analyzer?

A: Simply connect the analyzer to a standard 100-240 VAC / 50Hz power supply, position it for sampling exhaust gases, and use the user controls to initiate monitoring. Data is presented in real time, facilitating quick assessments.Q: Is the analyzer suitable for high-humidity environments?

A: The analyzer is recommended for use in environments where humidity is less than 85% RH, as excessive moisture may affect its performance and accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

SO2 Gas Analyzer

Price 328500 INR / Pack

Minimum Order Quantity : 1 Pack

Usage : Industrial

Power Supply : Electric

Voltage : 230 Volt (v)

Portable Trace Oxygen Analyser

Price 425000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Analyzer

Material : MS

Gas Transmiiter & Monitor

Price 15500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Power Supply : Electric

Material : Aluminium

Voltage : 230 Volt (v)

Online HCL Gas Analyzer Model ATS 208A

Price 375500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Material : MS

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry