- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Portable Nitrogen Gas Leak Detector

Price 24500 INR/ Case

Portable Nitrogen Gas Leak Detector Specification

- Power Supply

- Electric

- Accuracy

- +/- 2 %

- Features

- High Quality

- Dimension (L*W*H)

- 115 X 180 X 60 Millimeter (mm)

- Material

- ABS plastic

- Usage

- Industrial

- Display Type

- Digital

Portable Nitrogen Gas Leak Detector Trade Information

- Minimum Order Quantity

- 1 Case

- FOB Port

- Mumbai

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- 25 Cases Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Portable Nitrogen Gas Leak Detector

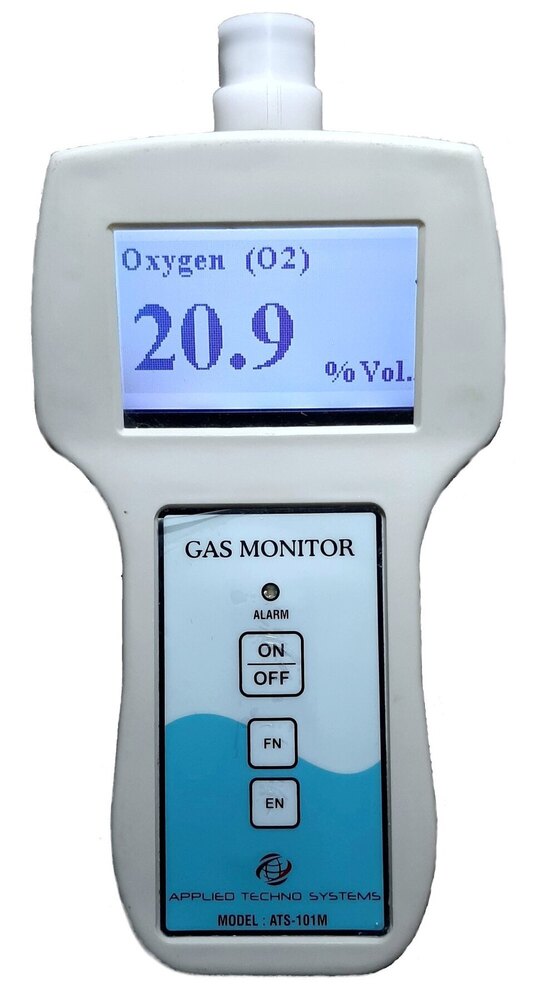

Portable Nitrogen Gas Leak Detector - Model ATS 101M

This Portable Nitrogen Gas Leak Detector uses embedded MCU micro control technology and high performance sensor to maintain accuracy in its work. Short response time, good repeatability and low maintenance design are the key characteristics of this instrument. Provided Portable Nitrogen Gas Leak Detector features ABS made burst proof housing which is also impact protected, skid proof back clamp and dust protected charging hole.

Features:-

- Complete Automatic Operation

- LCD Display

- Measurement Range: 0-25% & 0-100% V/V

- Continous Diffusion / Suction Sampling

- Confidence Beep every 15 Seconds

- Complete Self Integrity check on start

- Automatic Calibration

- Display of WARN & ALARM

- Low battery Alarm

- Specification:

- Overall Ranges: PPB / PPM/ % V/V % LEL

- Sampling Method: Diffusion (D) or Suction (S)

- Principal: Specific to Application

- Display: 128 x 64 graphics LCD

- Resolution: 0.1 or 1 PPM % as applicable

- Accuracy: +/- 2% & 0.5 for Oxygen

- Repeatability: +/-1%

- Response Time: <10 Seconds at 95% Variation

- Alarms: LOW & HI Visual and Audible

- Power Supply: 3.7 VDC Lithium Rechargeable Battary

- Housing: High Impact Plastic

- Temp Range: 0-55 deg C

- Battery Life: 6-8 hours

Precision in Leak Detection

Experience reliable nitrogen gas monitoring with this detector, offering an impressive accuracy of +/- 2%. The digital display enables quick and accurate leak identification, enhancing workplace safety and reducing downtime caused by undetected leaks. Designed for demanding industrial conditions, it brings peace of mind to operators and technicians alike.

Industrial-Grade Durability

Crafted from high-quality ABS plastic, the detector withstands harsh industrial conditions while remaining lightweight and portable. Its compact dimensions make it easy to use in tight spaces, ensuring flexibility and convenience during inspections. The robust material guarantees an extended lifespan, even with frequent usage in challenging environments.

Comprehensive Application Versatility

Ideal for exporters, importers, manufacturers, service providers, and suppliers, this nitrogen leak detector supports a broad range of industrial sectors across India. Its electric power supply ensures consistent operation, while its portable design facilitates ease of transport and deployment wherever gas leak detection is required.

FAQs of Portable Nitrogen Gas Leak Detector:

Q: How does the Portable Nitrogen Gas Leak Detector operate?

A: The detector works by sensing the concentration of nitrogen gas in the environment. When it detects abnormal levels indicating a possible leak, it displays the information digitally, allowing immediate response from the user.Q: What are the main benefits of using this gas leak detector in industrial settings?

A: This device enhances safety by quickly identifying nitrogen leaks, minimizes potential risks, and ensures compliance with industrial safety standards. Its high accuracy and durable build provide reliable performance over extended periods.Q: When should nitrogen gas leak detection be performed in an industrial facility?

A: Routine checks should be conducted during regular maintenance schedules or whenever theres suspicion of a leak. Additionally, it is advisable after any equipment installation or repair involving nitrogen lines.Q: Where can this Portable Nitrogen Gas Leak Detector be used?

A: It is suitable for use in various industrial environments across India, including manufacturing plants, storage facilities, laboratories, and any location where nitrogen gas is handled or stored.Q: What makes the construction of this detector robust for industrial use?

A: The detector is built with high-quality ABS plastic, providing exceptional durability against wear and tear. Its sturdy structure protects the sensitive internal components, ensuring reliable function in demanding conditions.Q: How do you properly use and maintain this nitrogen gas leak detector?

A: To ensure optimal performance, power on the device, follow the manufacturers calibration process, and scan suspected areas for leaks. Regularly inspect and clean the detector, and store it in a safe, dry place when not in use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Detector Category

CO Gas Transmitter

Price 26500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Continuous CO monitoring

Automation Grade : Automatic

Features : High sensitivity, Realtime monitoring, Long service life, Fault detection

LPG Gas Detector

Price 28500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Automation Grade : Semiautomatic

Features : Good Quality

Voltage : 110215 Volt (v)

Handheld VOC Monitor

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Automation Grade : Semiautomatic

Features : Good Quality

Voltage : 110215 Volt (v)

Online Hydrogen Gas Purity Analyzer Model ATS 208A

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Automation Grade : No

Features : Good Quality

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry