- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Stack Monitor

Price 275500 INR/ Box

Stack Monitor Specification

- Temperature

- 15 Celsius (oC)

- Power Source

- Electric

- Usage & Applications

- Industrial

- Display Type

- Digital

- Voltage

- 230 Volt (v)

- Weight

- 2.5 Kilograms (kg)

- Dimension (L*W*H)

- 430 X 150X 250 Millimeter (mm)

- Warranty

- 1 Year

Stack Monitor Trade Information

- Minimum Order Quantity

- 1 Box

- FOB Port

- Mumbai

- Supply Ability

- 20 Boxes Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Stack Monitor

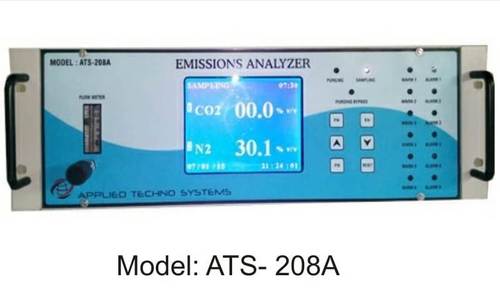

Stack Monitor Model ATS-208A

Special gas sample Conditioning systems are used to clean and dry the gas sample for accurate and High performance operation. An Internal Pump draw gas sample into the sensor through a dust particle filter from an intake which can be located at distance up to 40 meter form the monitor.

- Online Data transmission to CPCB & SPCB through GPRS/GSM technology

- The Sensor and Electronic component are housed in tough aluminium housing

Specifications:

- Principle:Electrochemical, TCD (Thermal Conductivity) , NDIR (Non Dispersive Infrared ), Zirconium and Paramagnetic

- Range: %V/V, % LEL, PPM, Mg/M3

- Resolution: 0.1 Unit or 1 Unit (Application based)

- Sampling Method: Auto Suction

- Display: 320 X 264 Graphic LCD

- Alarm; Relay Contact NO+NC

- Anolog Out Put: 4-20mA

- Digital Out Put : RS 232, RS 485 and Modbus Comminication Protocol

- Power Source:230VAC

- Accuracy: +/2%

- Response Time: <5 Second

- Sensor Life: 2-3 Years

Environmental:

- Temperature:-15degree Celsius Humidity :< 85%RH Atmosphere Pressure: 86- 106Kpa

- Dimension in mm: 430 (W) X 150(H) X 250(D)

- Weight: 2.5 KG

- Warranty: One Year

Precise Digital Monitoring for Industrial Needs

The Stack Monitor is engineered for seamless integration into industrial environments. Its digital display enables quick and precise readings while the robust construction ensures long-term reliability. The devices compact dimensions make it suitable for various installation points within a facility, optimizing space and functionality.

Convenience Paired with Dependability

Designed to operate at a stable 15C and powered by a standard 230V electric source, the Stack Monitor delivers dependable performance. The included warranty of 1 year highlights its quality assurance, providing peace of mind and protection for your investment.

FAQs of Stack Monitor:

Q: How is the Stack Monitor typically used in industrial applications?

A: The Stack Monitor is primarily used to continuously monitor and display temperature and other key parameters in industrial stacks or exhaust systems. Its digital interface provides precise, real-time data to help ensure safe and efficient operation.Q: What are the key benefits of using a digital display stack monitor?

A: A digital display offers enhanced visibility and accuracy, enabling operators to quickly assess stack conditions. This leads to improved safety, fast response to irregularities, and efficient regulatory compliance in industrial processes.Q: Where can the Stack Monitor be installed within an industrial facility?

A: Given its compact size (430 x 150 x 250 mm), the Stack Monitor can be mounted directly on or near stack outlets, control rooms, or wherever continuous monitoring is essential. Its lightweight build allows for flexible placement.Q: When should an industrial facility consider installing a stack monitoring system?

A: Stack monitors should be installed during the initial setup of exhaust systems or whenever there is a need to upgrade safety and compliance features. Regular monitoring becomes critical when maintaining emission standards and protecting equipment.Q: What is the process for purchasing the Stack Monitor in India?

A: You can acquire the Stack Monitor directly from suppliers, exporters, manufacturers, and service providers across India. Reach out for quotations, installation assistance, or after-sales service as needed.Q: How does the warranty benefit users of the Stack Monitor?

A: The 1-year warranty covers manufacturing faults and ensures prompt service or replacement, minimizing downtime and offering assurance of the products durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Quality Monitoring System Category

Handheld Air Quality Monitor with Data storage

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Material : ABS Plastic

Usage & Applications : Monitoring

Product Type : Monitor

Air Quality Monitor

Price 145500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 1 Year

Material : PVC Plastic

Usage & Applications : Industrial

Product Type : Air Quality Monitor

Air Pollution Gas Monitors

Price 78500 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : One Year

Material : ABS Plastic

Usage & Applications : For Industrial Use

Double Pass Dust Monitor

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 year

Material : Ms

Usage & Applications : Industrial

Product Type : Dust Monitor

Send Inquiry

Send Inquiry