- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

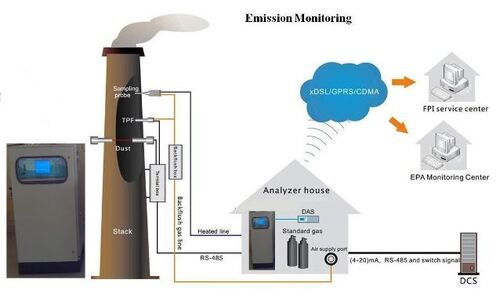

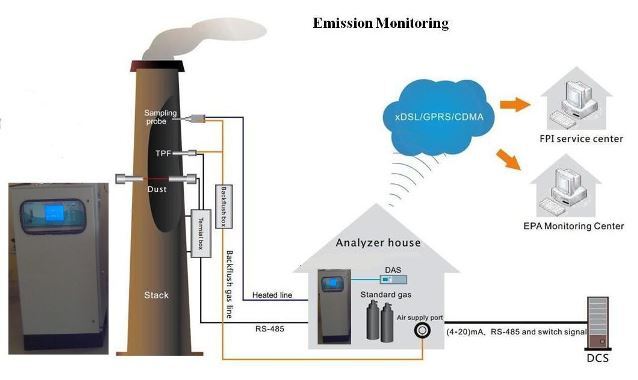

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

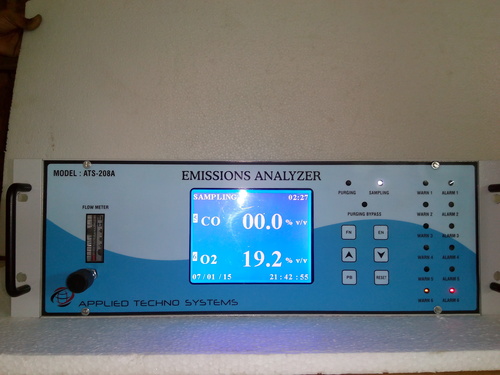

Stack Emissions Monitoring Systems

Price 450000 INR/ Number

Stack Emissions Monitoring Systems Specification

- Usage

- Industrial

- Voltage

- 230 Volt (v)

- Material

- Aluminium

- Humidity

- 85%RH

- Color

- Grey

- Power Supply

- Electric

About Stack Emissions Monitoring Systems

Competitive Edge & Industrial Application

Stack Emissions Monitoring Systems deliver pivotal performance in industrial environments, offering high reliability and precision at 85%RH humidity. Their aluminium build ensures longevity, while the grey color blends seamlessly into factory settings. Ideal for sectors like chemical, petrochemical, power, and general manufacturing, these systems enable real-time emission tracking, promoting regulatory compliance and environmental stewardship. Users gain a crackerjack advantage by integrating these systems into daily operations, ensuring both safety and efficiency.

FOB Port, Sample Availability & Supply Ability

Our monitoring systems are shipped promptly from major domestic portsvaluing both rapid handover and cost-effective delivery across Indias industrial landscape. Sample options are available for domestic clients, ensuring confident valuation before purchase. With reliable supply ability, we meet both bulk and small order demands, supporting tailored solutions for every valued customer. Experience hassle-free logistics and seamless integration, backed by our robust network and commitment to customer satisfaction.

FAQs of Stack Emissions Monitoring Systems:

Q: How does the Stack Emissions Monitoring System operate in high humidity environments?

A: The system is designed to function reliably at humidity levels up to 85%RH, ensuring accurate data collection even in challenging industrial conditions. Its aluminium build and electric power supply maintain performance and durability.Q: What are the principal advantages of using these systems in industrial settings?

A: Primary benefits include real-time emissions monitoring, regulatory compliance, enhanced workplace safety, and minimized environmental impact. Its pivotal role helps industries consistently manage and track stack emissions.Q: When can customers request a sample before purchase?

A: Domestic clients may request sample units during the initial valuation and selection process to assess product suitability prior to bulk ordering and formal handover.Q: Where are the Stack Emissions Monitoring Systems shipped from and to?

A: Products are shipped from major domestic ports in India, with supply networks covering both domestic and international markets. Our logistics facilitate both large and small order deliveries efficiently.Q: What is the process for ordering and receiving Stack Emissions Monitoring Systems?

A: Customers can initiate orders directly through our sales channels. Upon confirmation, systems are shipped from chosen FOB ports with samples available for evaluation. Supply ability ensures prompt product handover for all clients.Q: How can these monitoring systems benefit manufacturing operations?

A: By utilizing these crackerjack systems, manufacturers achieve precise emissions tracking, improved compliance, and operational efficiency, bolstering both reputation and environmental accountability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Environmental Emissions Monitoring Systems

Price 1050000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Continuous Monitoring, RealTime Data, Multiparameter Detection

Display Type : Graphics Display

Power Supply : 220 V AC, 50 Hz

Temperature : 10C ~ 50C

Online Continuous Emission Monitoring Systems (OCEMS)

Price 586500.00 INR / Set

Minimum Order Quantity : 1 Set

Features : High Quality

Display Type : Digital

Power Supply : 230 VAC

Temperature : 40 to +50 Celsius (oC)

Industrial Stack Monitoring System

Price 62500 INR / Set

Minimum Order Quantity : 1 Set

Features : High Quality

Display Type : Digital

Power Supply : Electric

Temperature : 15 Celsius (oC)

Continuous Emission Monitoring System

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Features : High Quality

Display Type : Digital

Power Supply : Electric

Temperature : 5 to 55 Celsius (oC)

Send Inquiry

Send Inquiry