- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

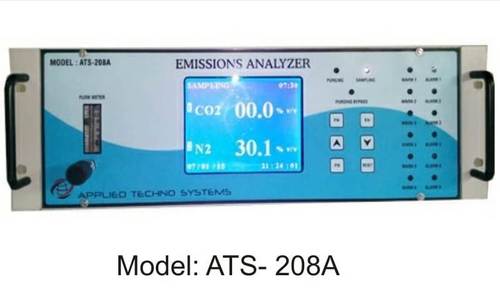

Air Pollution Gas Monitors

Price 78500 INR/ Unit

MOQ : 1 Unit

Air Pollution Gas Monitors Specification

- Usage & Applications

- For Industrial Use

- Display Type

- Liquid Crystal Display(LCD)

- Power Source

- Electric

- Sensor Type

- TCD, IR or EC

- Material

- ABS Plastic

- Warranty

- One Year

Air Pollution Gas Monitors Trade Information

- Minimum Order Quantity

- 1 Unit

- Packaging Details

- As Per Customer Requirement

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About Air Pollution Gas Monitors

Air Pollution Gas Monitors are devices used to detect and measure the concentration of harmful gases in the atmosphere to ensure environmental safety and regulatory compliance.Typical gases include:

- Sulfur Dioxide (SO)

- Nitrogen Dioxide (NO)

- Carbon Monoxide (CO)

- Ozone (O)

- Volatile Organic Compounds (VOCs)

- Carbon Dioxide (CO)

These monitors are used in

- Urban air quality monitoring stations

- Industrial areas (factories, power plants)

- Construction sites

- Traffic-heavy zones

- Indoor air quality assessments

- Research and environmental studies

Sensors are used in these monitors are -

- Electrochemical Sensors (for CO, NO, SO)

- Non-Dispersive Infrared (NDIR) Sensors (for CO)

- Photoionization Detectors (PIDs) for VOCs

- Laser Scattering Sensors (for PM)

Accuracy varies by model and sensor type. Regulatory-grade monitors offer high precision (+/-5%), while low-cost sensors may have +/-10% accuracy. Calibration greatly affects accuracy.

Robust Industrial Performance

Engineered for industrial use, these gas monitors are built with high-quality ABS plastic, making them resilient in demanding environments. The integration of TCD, IR, or EC sensors enables effective detection of various hazardous gases, supporting plant safety and compliance with regulatory standards.

Easy-to-Read LCD Display

The large Liquid Crystal Display (LCD) provides real-time readings with clarity. Users benefit from quick and accurate detection information, facilitating on-the-spot decisions and maintenance planning for efficient industrial processes.

FAQs of Air Pollution Gas Monitors:

Q: How does the Air Pollution Gas Monitor operate?

A: The Air Pollution Gas Monitor operates by using TCD, IR, or EC sensors to detect and measure specific gases in industrial settings. Powered by electricity, it continuously monitors gas concentrations and displays real-time data on an integrated LCD.Q: What types of gases can be detected using these monitors?

A: These monitors can detect a broad range of industrial gases, including toxic, flammable, and greenhouse gases, depending on the chosen sensor type (TCD, IR, or EC). This versatility ensures suitability for various industrial applications.Q: When should the gas monitor be calibrated or maintained?

A: It is recommended to calibrate the gas monitor regularly as part of routine maintenance, generally every 6 to 12 months, or as per manufacturer guidelines, to maintain accuracy and reliability in readings.Q: Where can these monitors be installed in an industrial facility?

A: The monitors are designed for flexible installation in areas prone to gas exposure, such as manufacturing plants, processing units, or storage facilities. Placement should ensure optimal detection and safety coverage.Q: What is the usage process for the Air Pollution Gas Monitor?

A: Installation is straightforward: simply position the device in the designated area, power it on using the electric source, and monitor gas levels via the LCD display. Routine calibration and scheduled maintenance help ensure ongoing accuracy.Q: What benefits do industrial users gain from these monitors?

A: Industrial users benefit from enhanced workplace safety, regulatory compliance, early warning of hazardous gas concentrations, and reduced risk of operational downtime, all supported by reliable gas detection and a one-year warranty.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Air Quality Monitoring System Category

Stack Monitor

Price 275500 INR / Box

Minimum Order Quantity : 1 Box

Usage & Applications : Industrial

Warranty : 1 Year

Handheld Air Quality Monitor with Data storage

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Monitoring

Warranty : One Year

Material : ABS Plastic

Product Type : Monitor

Air Quality Monitor

Price 145500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Industrial

Warranty : 1 Year

Material : PVC Plastic

Product Type : Air Quality Monitor

PM-10, PM-2.5 Air Monitoring System

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Industrial

Warranty : 1 year

Material : Plastic

Product Type : Air Monitoring System

Send Inquiry

Send Inquiry