- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Argon purity analyzer

Price 158000 INR/ Number

Argon purity analyzer Specification

- Temperature

- -20C to 50 Celsius (oC)

- Color

- Grey

- Voltage

- 240 Volt (v)

- Material

- Aluminium

- Usage

- Industrial

- Dimension (L*W*H)

- 30x20x15 Centimeter (cm)

- Gas Pressure

- 1-10 Bar

- Power Supply

- Electric

About Argon purity analyzer

Argon Purity Analyzer Specifications

Measurement Range:

- 0-100% argon

- Impurity detection down to ppm levels (e.g., O, N, HO).

Accuracy: ±0.1% of reading.

Precision: Repeatability ±0.05%.

Response Time: <30 seconds.

Operating Conditions:

- Temperature: -20C to 50C

- Pressure: 1-10 bar.

Detection Technology: Gas chromatography or thermal conductivity.

Calibration: Automatic calibration with certified gas standards.

Output Options: Analog (4-20 mA), digital (USB, Ethernet).

Display: LCD touchscreen with user-friendly interface.

Dimensions: Compact design (e.g., 30x20x15 cm).

Power Supply: 100-240V AC, <50W.

Environmental Rating: IP65 for dust and moisture resistance.

Warranty: 1-2 years with technical support.

Advanced Argon Analysis

Engineered for reliability and accuracy, the Argon Purity Analyzer delivers precise measurements for industrial environments. Its aluminium construction ensures durability, while its 240V electric operation provides consistent performance, even in varying temperatures from -20C to 50C. Compact in design, it fits seamlessly into existing setups and adapts to argon gas pressures ranging from 1 to 10 bar, offering versatility for a wide range of applications.

Industrial-Grade Versatility

As both a manufacturer and supplier in India, the Argon Purity Analyzer meets the strict standards expected in industrial sectors. Its flexible usage covers production, quality control, and laboratory testing. The analyzers robust build and efficient energy consumption make it ideal for continuous operation in professional settings. Comprehensive service support ensures reliability throughout its lifecycle, whether for end-users or resellers.

FAQs of Argon purity analyzer:

Q: How does the Argon Purity Analyzer function in industrial applications?

A: The analyzer measures the purity of argon gas by sampling and analyzing the gas at pressures between 1 to 10 bar, providing accurate readings essential for quality control in industrial processes.Q: What materials is the Argon Purity Analyzer constructed from, and why does it matter?

A: Constructed from durable aluminium, the analyzer is designed to withstand harsh industrial environments, offering protection against wear, corrosion, and temperature fluctuations.Q: When is the optimal time to use an Argon Purity Analyzer in a production process?

A: It is best used before, during, and after argon gas is utilizedin stages like gas delivery, in-line use, or quality verificationto ensure gas purity standards are consistently met.Q: Where can this analyzer be installed or used within an industrial facility?

A: Thanks to its compact dimensions (30x20x15 cm), the analyzer can be integrated into various settings such as production lines, laboratories, or near gas delivery systems.Q: What is the process for operating the analyzer?

A: To operate, simply connect the analyzer to an argon gas line (with pressures between 110 bar), power it with a 240V supply, and follow the devices interface to obtain purity measurements.Q: How does using this analyzer benefit industrial gas users?

A: By ensuring high purity argon gas, the analyzer helps prevent contamination, enhances product quality, and maintains compliance with industry standards, thus reducing operational risks and costs.Q: Who can provide support, maintenance, and supply for this analyzer in India?

A: Exporters, importers, manufacturers, service providers, and suppliers across India offer sales, service support, and spare parts to ensure smooth operation and maintenance of the analyzer.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

N2 Purity Analyser

Price 128000 INR / Unit

Minimum Order Quantity : 1 Unit

Temperature : 0C to 50C

Power Supply : 230V AC, 50 Hz

Usage : Instant Nitrogen Gas Purity Analysis

Humidity : 0 95% RH (noncondensing)

Portable Emission analyzer

Price 158000 INR / Number

Minimum Order Quantity : 1 Number

Temperature : 10 to +50 Celsius (oC)

Power Supply : Electric

Usage : Industrial

Humidity : 95%

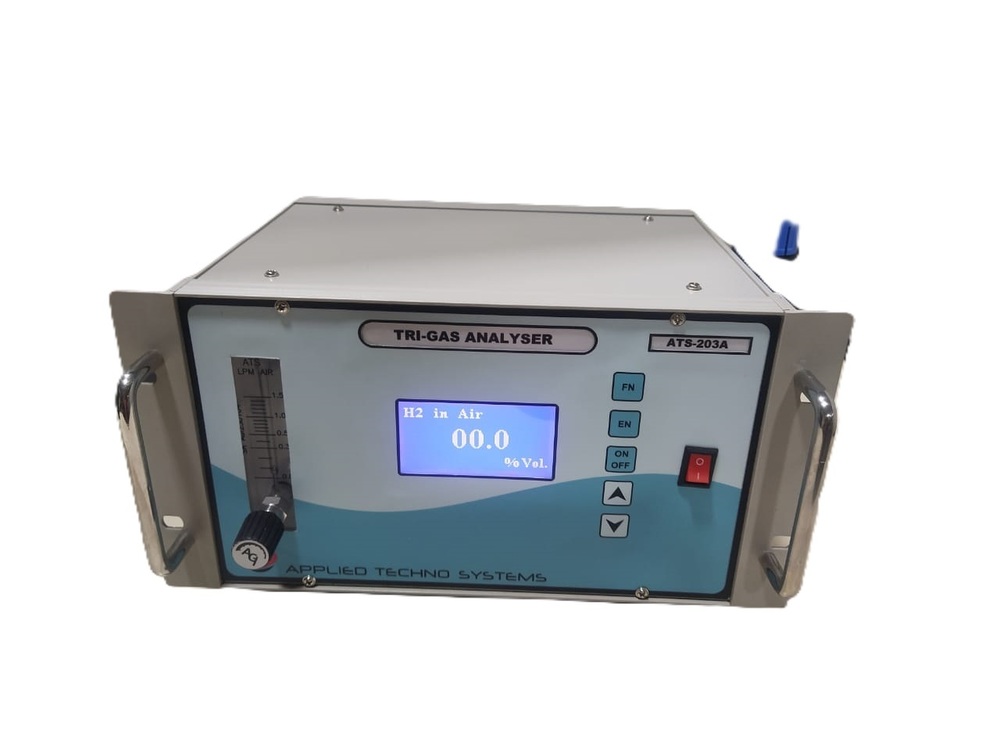

ATS-203 Turbine Gas Analyzer

Price 375500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Online Stack Gas Analyser

Price 800000 INR / Number

Minimum Order Quantity : 1 Number

Temperature : 5 to 55 Celsius (oC)

Power Supply : 230V AC

Humidity : 95%

Send Inquiry

Send Inquiry