- Dew Point Meters

- Gas Analysers

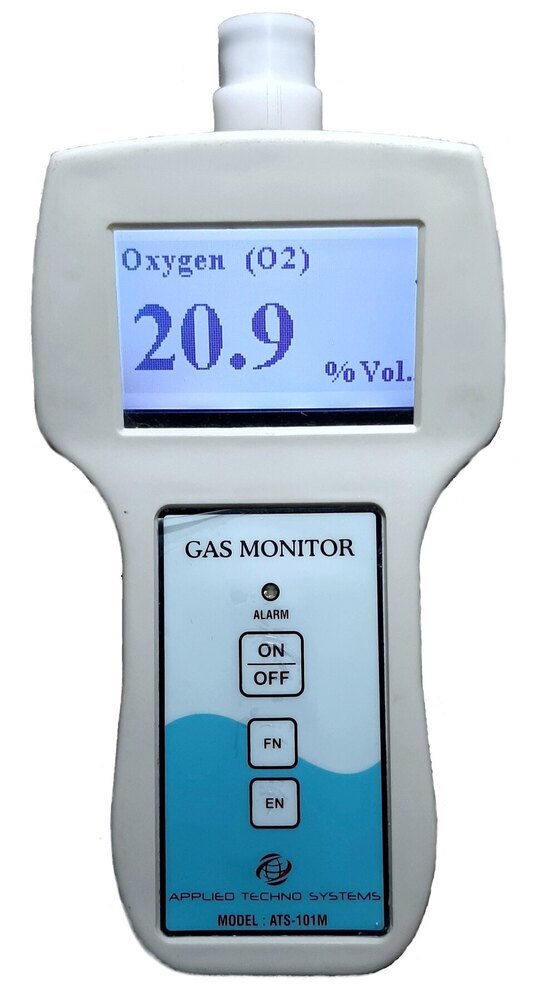

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Bio Gas/ Syn gas Analyzer

Price 195000 INR/ Unit

Bio Gas/ Syn gas Analyzer Specification

- Temperature

- -5 to 55 Celsius (oC)

- Voltage

- 220 Volt (v)

- Humidity

- 85%RH

- Usage

- Industrial

- Material

- Aluminium

- Power Supply

- Electric

- Weight

- 1.5 Kilograms (kg)

- Dimension (L*W*H)

- 170 X 100 X 130 Millimeter (mm)

- Color

- Grey

Bio Gas/ Syn gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Bio Gas/ Syn gas Analyzer

A biogas/syngas analyzer is a specialized instrument used to measure and analyze the composition of biogas and synthesis gas (syngas) in real time. These gases are primarily produced from the anaerobic digestion of organic materials (biogas) and gasification of carbon-containing materials (syngas). Accurate analysis of these gases is crucial for optimizing production processes, ensuring safety, and complying with environmental regulations.

Key Features:

- Multi-Gas Measurement: Capable of measuring several key components, including methane (CH4), carbon dioxide (CO2), hydrogen (H2), carbon monoxide (CO), hydrogen sulfide (H2S), and nitrogen (N2).

- Real-Time Monitoring: Provides continuous data on gas composition, enabling immediate adjustments to production processes and improving efficiency.

- Advanced Sensor Technology: Utilizes various technologies, such as infrared spectroscopy, electrochemical sensors, and thermal conductivity detection, to achieve accurate measurements.

- User-Friendly Interface: Often features a digital display for easy reading of real-time data, historical trends, and alarm conditions.

- Data Communication: Equipped with communication protocols (e.g., Modbus, Ethernet) for integration with control systems and data logging.

- Alarm and Safety Features: Includes built-in alarms that activate when gas concentrations exceed safety thresholds, helping to prevent hazardous situations.

Applications:

- Waste Management: Used in landfills and wastewater treatment plants to monitor biogas production and optimize anaerobic digestion processes.

- Energy Production: Essential for monitoring syngas in gasification processes for bioenergy production.

- Environmental Compliance: Helps in emissions monitoring to ensure compliance with environmental regulations related to gas emissions.

FAQs

What gases can a biogas/syngas analyzer measure?

A biogas/syngas analyzer typically measures gases such as methane (CH4), carbon dioxide (CO2), hydrogen (H2), carbon monoxide (CO), hydrogen sulfide (H2S), and nitrogen (N2).

How does a biogas/syngas analyzer work?

These analyzers use various technologies like infrared spectroscopy and electrochemical sensors to detect gas concentrations and provide real-time analysis.

What industries commonly use biogas/syngas analyzers?

They are used in industries such as waste management, renewable energy production, agriculture, and environmental monitoring.

How often should a biogas/syngas analyzer be calibrated?

Calibration frequency varies based on the application and manufacturer recommendations, typically every 6 to 12 months.

What is the typical output signal from a biogas/syngas analyzer?

The output may include analog signals (4-20 mA) and digital communication protocols (e.g., Modbus, Ethernet) for integration with control systems.

Can biogas/syngas analyzers be used for emissions monitoring?

Yes, they are essential for monitoring emissions and ensuring compliance with environmental regulations regarding gas emissions.

What maintenance is required for a biogas/syngas analyzer?

Regular maintenance includes cleaning sensors, checking calibration, and replacing filters if applicable to ensure accurate readings.

What factors can affect the performance of a biogas/syngas analyzer?

Environmental conditions such as temperature, humidity, and the presence of interfering gases can impact performance. Regular calibration and proper maintenance help mitigate these effects.

Are biogas/syngas analyzers portable?

Some models are designed for portability, allowing for field measurements, while others are fixed installations for continuous monitoring.

How do I interpret the readings from a biogas/syngas analyzer?

Readings are displayed on the device's screen, showing the concentration of each measured gas. Users should refer to the manufacturer's manual for specific instructions on interpreting results and understanding alarm conditions.

Efficient Gas Analysis for Industries

Our Bio Gas/Syn Gas Analyzer offers rapid and reliable measurement of gas components, ensuring quality control in biogas plants and industrial applications. With its electric power supply and sturdy aluminium build, the device delivers consistent performance even under challenging environmental conditions, from -5C to 55C and up to 85% humidity.

Compact and Robust Design

The analyzers dimensions (170 x 100 x 130 mm) and light weight (1.5 kg) allow for easy installation and portability. Its aluminium enclosure provides excellent durability and resistance to industrial wear, making it ideal for both indoor and outdoor usage.

FAQs of Bio Gas/ Syn gas Analyzer:

Q: How does the Bio Gas/Syn Gas Analyzer operate in industrial environments?

A: The analyzer is powered by a 220V electric supply and can function reliably in industrial settings with humidity up to 85% RH and temperatures ranging from -5C to 55C, ensuring accurate analysis under typical operational conditions.Q: What process does the analyzer use to detect gas composition?

A: It utilizes advanced sensor technology to measure and analyze the chemical composition of biogas and syngas, providing real-time data to support process optimization and compliance with industry standards.Q: When should the Bio Gas/Syn Gas Analyzer be used during production?

A: The analyzer is best employed during routine gas production, quality checks, and when adjusting or calibrating gas systems, ensuring continuous monitoring and quality assurance throughout industrial operations.Q: Where can the analyzer be installed within an industrial setup?

A: Due to its compact design and robust material, the device can be easily placed near gas production units, pipelines, or control panels, as required by the facilitys layout and monitoring needs.Q: How is the analyzer beneficial to manufacturers and service providers?

A: By enabling precise gas composition analysis, the device helps manufacturers and service providers optimize production processes, maintain safety standards, and increase overall efficiency.Q: What are the recommended usage and maintenance practices for this analyzer?

A: For optimal performance, install the analyzer in a clean, stable location, adhere to the recommended voltage, and periodically calibrate and service the device according to the manufacturers guidelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Online Gas Monitoring System

Price 950000 INR / Set

Minimum Order Quantity : 1 Set

Usage : GAS EMISSION MONITORING

Power Supply : 230V AC

Humidity : < 85%RH

Headspace Gas Analyser

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Power Supply : Electric

Online CO2 Gas Purity Analyzer Model ATS 208A

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Power Supply : Electric

Automatic Nitrogen Purity Analyzer

Price 65500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Send Inquiry

Send Inquiry