- Dew Point Meters

- Gas Analysers

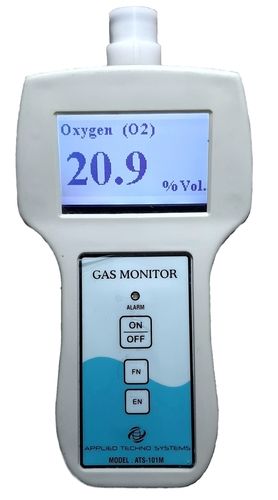

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Fixed Ammonia Gas Detection System

Price 22500 INR/ Pack

Fixed Ammonia Gas Detection System Specification

- Power Supply

- 24V DC or 230 V AC

- Test Range

- 0-1000 PPM

- Temperature

- -5 to 55 deg C Celsius (oC)

- Gas Pressure

- 1.5 kgf/cm2

- Humidity

- 95% RH

- Port Size

- 3/4

- Usage

- Gas Leak Monitoring

- Control Mode

- Manual

Fixed Ammonia Gas Detection System Trade Information

- Minimum Order Quantity

- 1 Pack

- FOB Port

- Mumbai

- Supply Ability

- 25 Packs Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Fixed Ammonia Gas Detection System

Features:

- Low maintenance cost

- Non corrosive body

Other Details:

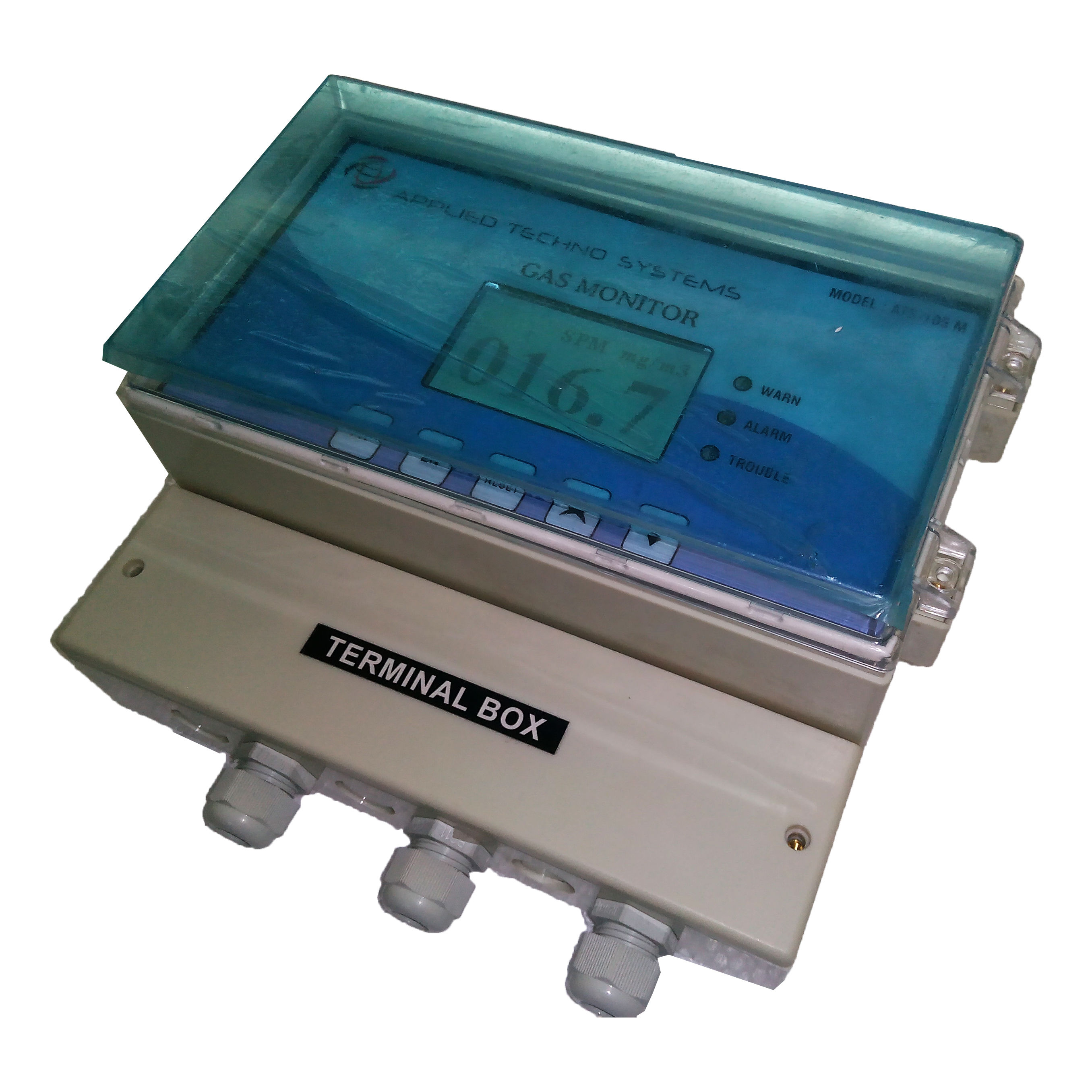

- Model ATS-105M is Single channel Ammonia gas Monitor for environmental Monitoring and Leak detection.

- The ATS-105M is an economical, yet versatile Multi channel controller with the features needed for monitoring a remote 4-20 mA gas sensor/transmitter or similar device.

- The instrument provides 24 VDC power, audio/visual alarms, alarm relays and other features.

- The ATS-105M is easy to install, designed for wall mounting and completely programmable from the front panel membrane switches

Ammonia Gas Tranmsitter

The ATS-109TD Sensor/Transmitter with without Display operates on 24 VDC power and 4-20 mA output and optional alarm relay board. This sensor/transmitter can be connected to various applied controllers or computer-based instrumentation, such as PLC or similar instrumentation.

The ATS-109TD Ammonia (NH3) Sensor/Transmitters utilize electrochemical type cells to detect the target gas. These cells consist of electrodes, electrolyte and an air/liquid separation barrier. Gas molecules enter the cell and, as a result of an oxidation/reduction reaction, generate an electrical current proportional to the gas concentration

Specifications:

- Principle: Electrochemical, Solid State Semiconductor Catalytic and PID.

- Range: PPM/PPB or mg/M3.

- Resolution: 0.1 Unit or 1 Unit (Application based)

- Sampling Method: Diffusion

- Display: 128 X 64 Graphics LCD

- Alarm; Relay Contact NO+NC

- Anolog out Put: 4-20mA

- Digital out Put: RS 232, RS 485 and Modbus Communication Protocol

- Power Source: 230V AC

- Accuracy: +/2%

- Response Time: Data Storage: 1000 or 10000

- Sensor Life: 2-3 Years

Environmental:

- Temperature:-15 degree Celsius Humidity :< 85%RH Atmosphere Pressure: 86- 106Kpa

- Dimension in mm: 210 (W) X 180(H) X 110(D)

- Weight: 1.2 KG

- Warranty: One Year

Comprehensive Ammonia Leak Detection

Our Fixed Ammonia Gas Detection System provides robust and round-the-clock monitoring for ammonia leaks, enabling early detection and safety control. With a wide test range and adaptable port size, it integrates seamlessly with diverse industrial environments, enhancing workplace safety and regulatory compliance.

Built for Indian Industrial Needs

Designed to meet the demanding environmental conditions common in Indian industries, the system operates flawlessly in high humidity and extreme temperatures. Whether you are an exporter, importer, manufacturer, or supplier, this detection system offers reliability and ease of installation.

FAQs of Fixed Ammonia Gas Detection System:

Q: How does the Fixed Ammonia Gas Detection System operate?

A: The detector continuously monitors for ammonia concentrations in the air. If leakage is detected within its 01000 PPM range, the user is alerted, allowing prompt manual intervention to prevent hazardous situations.Q: What are the installation requirements for this detection system?

A: The unit requires a power supply of either 24V DC or 230V AC and is designed for installation at points where ammonia leaks are likely, such as gas pipelines or storage tanks. It is fitted using a 3/4-inch port.Q: When should this system be used in an industrial setting?

A: It should be installed in any environment where ammonia is stored, handled, or processed, to ensure continuous gas leak monitoring and protect personnel and property from accidental exposure.Q: Where is this ammonia gas detector most effectively deployed?

A: This system is best deployed in areas vulnerable to ammonia leaks, such as chemical plants, refrigeration facilities, and storage areas. Its robust construction makes it suitable for both indoor and semi-outdoor usage.Q: What is the process for maintaining the Fixed Ammonia Gas Detection System?

A: Regular inspection and occasional calibration by qualified personnel are recommended to ensure sensor accuracy. The systems manual control mode allows for convenient testing and verification during maintenance.Q: How does this system benefit exporters, importers, and manufacturers in India?

A: By providing real-time leak alerts, the system helps prevent operational downtime and costly accidents, ensuring compliance with safety standards and fostering a secure work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Detector Category

Portable Hydrogen Gas Leak Meter

Price 32500 INR / Piece

Minimum Order Quantity : 1 , , Unit

Usage : Detection Of Hydrogen

Display Type : Digital

Features : High Quality

Gas Leak Detector

Price 31500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : ABS Plastic

Display Type : Digital

ATS-208A LPG Gas Leak Detector

Price 95500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Features : Good Quality

Oxygen Gas Meters

Price 25000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Material : ABS Plastic

Display Type : Digital

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese