- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

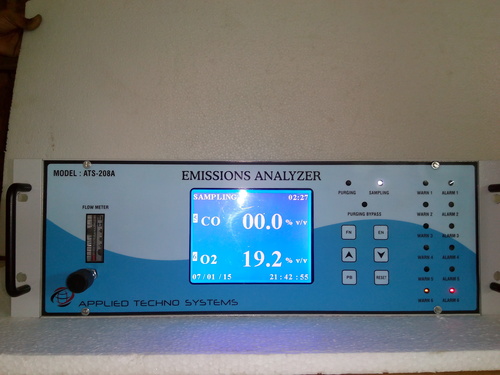

Gas Emission Analyzer

Price 950000 INR/ Unit

Gas Emission Analyzer Specification

- Humidity

- < 85%RH

- Usage

- Industrial

- Accuracy

- +2 C

- Temperature

- 15 Celsius (oC)

- Display Type

- Digital

- Power Supply

- Electric

- Features

- High Quality

About Gas Emission Analyzer

| Brand | Applied Techno Systems |

| Application | Industrial Use |

| Product Type | Stack Emission Monitor |

| Automation Grade | Automatic |

| Display Type | Graphics LCD |

| Response Time | Less than 30 Sec |

| Power | 230 V AC 50Hz |

| Power Supply | 230 V AC 50Hz |

Reliable Gas Emission Analysis

Our analyzer provides industrial users with accurate gas emission readings, supporting regulatory compliance and safety initiatives. The digital display enables rapid access to real-time data, facilitating prompt decision-making and system adjustments. Designed with robust components, it delivers dependable performance even under challenging conditions common in industrial settings.

Versatile Industrial Application

From manufacturing plants to energy production facilities, our emission analyzer is suitable for a wide range of industrial scenarios. Its adaptability and consistent operation at standard temperature and humidity levels make it a trusted choice for monitoring environmental impact and process safety. Service and support are available throughout India.

FAQs of Gas Emission Analyzer:

Q: How does the Gas Emission Analyzer ensure accurate measurements in industrial environments?

A: It utilizes advanced sensors and digital processing to produce measurements with an accuracy of 2C. This ensures that emission data is reliable, aiding in monitoring compliance and maintaining process safety in industries.Q: What is the temperature and humidity operating range for this analyzer?

A: The device operates optimally at a temperature of 15C and can function effectively in environments where the humidity is below 85% RH, making it suitable for most industrial conditions.Q: When should the Gas Emission Analyzer be used in industrial processes?

A: It should be employed during regular emissions monitoring, maintenance checks, and whenever there is a need to verify compliance with environmental regulations or assess system performance.Q: Where can the Gas Emission Analyzer be installed within an industrial setup?

A: It can be placed in any area requiring emission monitoring, such as production lines, exhaust outlets, or air quality control stations within industrial facilities.Q: What is the process for operating this analyzer and viewing results?

A: Users power the electric analyzer, position it appropriately, and use the digital display to view real-time gas emission readings. Routine calibration as per manufacturer guidelines ensures optimal performance.Q: How does using this analyzer benefit industrial operations in India?

A: It provides precise emission data, facilitating better compliance with local regulations, minimizing environmental impact, and supporting safer workplace conditions. The high-quality build ensures longevity and reliable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Environmental Emissions Monitoring Systems

Price 1050000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 220 V AC, 50 Hz

Display Type : Graphics Display

Temperature : 10C ~ 50C

Humidity : 5% ~ 95% RH (Noncondensing)

Industrial Stack Monitoring System

Price 62500 INR / Set

Minimum Order Quantity : 1 Set

Power Supply : Electric

Display Type : Digital

Temperature : 15 Celsius (oC)

Humidity : < 85%RH

Continuous SO2 Monitoring System

Price 380500.00 INR / Set

Minimum Order Quantity : 1 Set

Power Supply : Electric

Display Type : Digital

Temperature : 15 Celsius (oC)

Humidity : < 85%RH

Exhaust gas monitoring

Price 725000 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : Electric

Display Type : Digital

Temperature : 40 Deg C to 55 Celsius (oC)

Humidity : 85%RH

Send Inquiry

Send Inquiry