- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Hydrogen Gas Transmitter

Price 52400 INR/ Pack

Hydrogen Gas Transmitter Specification

- Product Type

- Sensor transmitter

- Material

- Flameproof

- Input

- 24 V DC

- Output

- 4-20mA, Relay output, RS-485

- Function

- leak detection

- Usage

- gas leak detection

- Accuracy

- +/-2 %

- Resolution

- 0.1

- Voltage

- 24 Volt (v)

- Weight

- 450 Grams (g)

- Warranty

- 1 Year

Hydrogen Gas Transmitter Trade Information

- Minimum Order Quantity

- 1 Pack

- FOB Port

- Mumbai

- Supply Ability

- 50 Packs Per Week

- Delivery Time

- 1-2 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal packing with thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Hydrogen Gas Transmitter

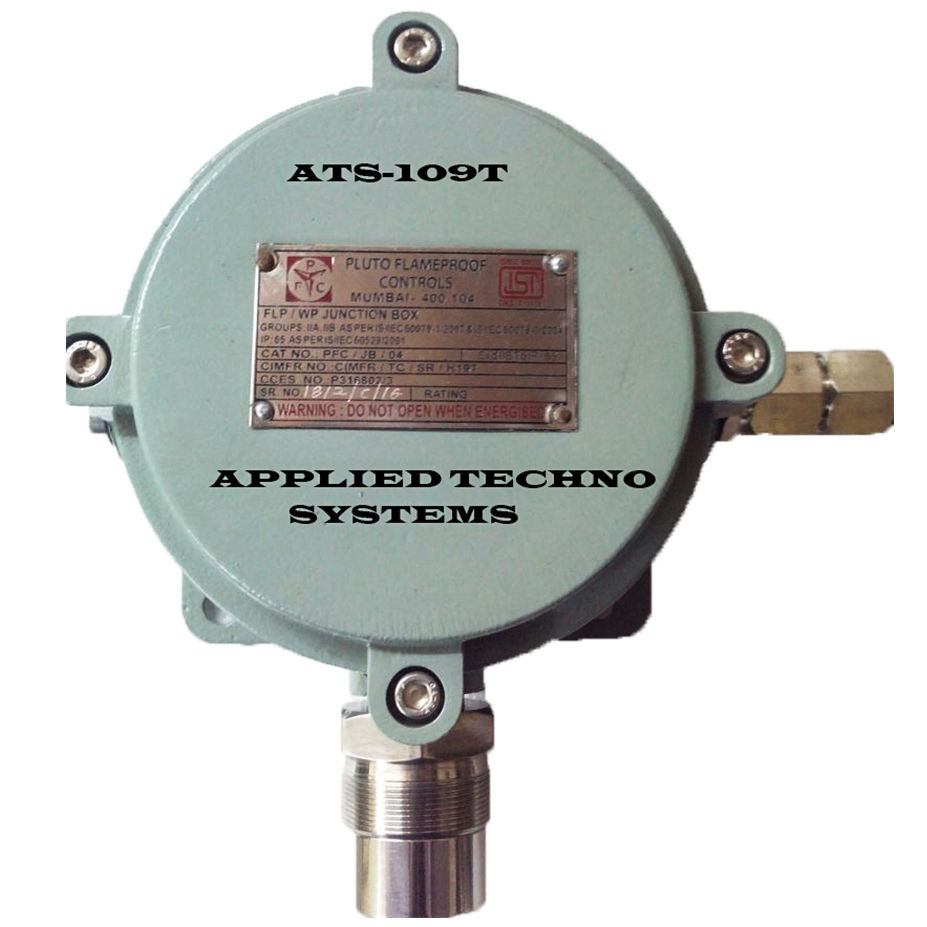

Hydrogen Gas Transmitter Model ATS-109TD

Counted amidst the reliable firms, we are consistently engaged in manufacturing, exporting and supplying a broad range of Hydrogen Gas Transmitter. Used to determine the hydrogen gas leakage, offered transmitter is featured with quality checked sensors, alarms and indicators. Our deft professionals manufacture the offered transmitter using progressive technology. Besides, the provided Hydrogen Gas Transmitter can be bought from us at reasonable prices within promised time frame.

Key Points:

- High operational fluency

- Easy to operate

- Sturdy design

- Long working life

Specifications:

- Principle: Electrochemical, Solid State Semiconductor and Catalytic

- Range: %V/V, % LEL, PPM, PPB

- Resolution: 0.1 Unit or 1 Unit (Application based)

- Sampling Method: Diffusion

- Display: Alphanumeric LED

- Alarm; Relay Contact NO+NC

- Analog Out Put: 4-20mA

- Digital Out Put : RS 232, RS 485 and Modbus Communication Protocol

- Power Source: 24V DC or 230VAC

- Accuracy: +/2%

- Response Time: <5 Second

- Sensor Life: 2-3 Years

- Environmental:

- Temperature:-15degree Celsius Humidity :< 85%RH Atmosphere Pressure: 86- 106Kpa

- Dimension in mm: 120 (W) X 125(H) X 1120(D)

- Weight: 1.2 KG

- Warranty: One Year

Advanced Leak Detection Technology

This hydrogen gas transmitter incorporates state-of-the-art sensors with a high resolution of 0.1, allowing it to detect even minor gas leaks promptly. The design ensures swift transmission of alerts through its relay output, keeping operational sites secure and reducing risk to personnel and assets.

Durable and Safe Flameproof Design

Crafted from flameproof materials, the device is ideally suited for hazardous industrial areas where explosive gases could be present. Its sturdy build and lightweight design ensure ease of installation while maintaining compliance with stringent safety standards.

Versatile Output and Communication Options

The transmitter supports both 4-20mA and RS-485 outputs, offering compatibility with varied control and monitoring systems. This flexibility enables seamless integration into existing safety infrastructures, enhancing continuous protection and operational efficiency.

FAQs of Hydrogen Gas Transmitter:

Q: How does the hydrogen gas transmitter detect leaks?

A: The transmitter utilizes sensitive sensors capable of detecting hydrogen gas concentrations at a resolution of 0.1. When the detected level exceeds a pre-set threshold, it triggers an alert via the relay output or sends a signal through its communication interfaces.Q: What are the primary benefits of using this hydrogen gas transmitter?

A: The key benefits include high accuracy (+/-2%), flameproof construction for safety in hazardous areas, versatile output options (4-20mA, relay, RS-485), and ease of installation and integration. These make it a reliable choice for industrial gas leak detection.Q: When should this device be installed in an industrial facility?

A: It is advisable to install the hydrogen gas transmitter during the initial setup of gas-handling equipment or when upgrading safety systems in environments where hydrogen leaks could pose a risk, ensuring continuous protection from potential hazards.Q: Where can this transmitter be effectively utilized?

A: This device is best used in industrial locations such as chemical plants, refineries, manufacturing units, and any area where hydrogen gas is stored or transported. Its flameproof design makes it suitable for hazardous or potentially explosive atmospheres.Q: What is the process for installing and connecting the transmitter?

A: Installation involves securely mounting the lightweight (450g) unit in the desired location, connecting the 24 V DC input, and wiring output signals (4-20mA, relay, or RS-485) to the facilitys monitoring or alarm systems. Professional assistance is recommended to ensure safe setup.Q: How is the accuracy of the transmitter maintained during operation?

A: The device maintains an accuracy of +/-2% through its precision-built sensors and regular factory calibration. For continued reliability, annual servicing or calibration is recommended, ideally during scheduled maintenance routines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Transmitters Category

Gas Sensor

Price 15600.0 INR / Piece

Minimum Order Quantity : 1 Piece

Accuracy : 2 %

Voltage : 24VDC Volt (v)

Material : Flameproof

Usage : Gas Detection

Flame Proof Oxygen Gas Sensor Transmitter

Price 28500 INR / Unit

Minimum Order Quantity : 1 Unit

Accuracy : 2% F.S.

Voltage : 24V DC

Material : Flameproof Aluminium Alloy Enclosure

Usage : Industrial Gas Detection and Safety

Gas Sensor Transmitter

Price 8502 INR / Pack

Minimum Order Quantity : 1 Pack

Accuracy : 2 %

Usage : transmitter

Oxygen Sensor Transmitter

Price 20600 INR / Pack

Minimum Order Quantity : 1 Pack

Accuracy : +/1% and +/0.5% for O2 %

Voltage : 24 Volt (v)

Material : Aluminium

Send Inquiry

Send Inquiry