- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

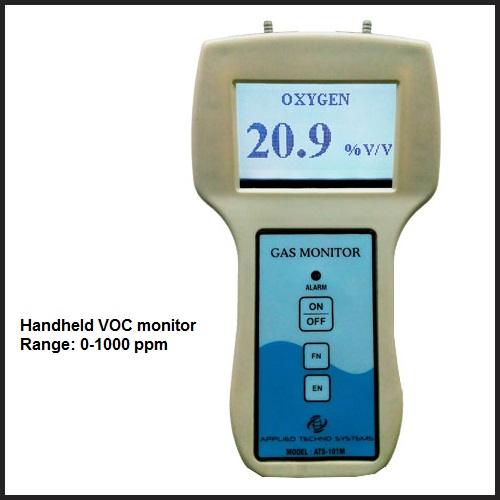

Industrial Oxygen Monitor

Price 25500.0 INR/ Pack

Industrial Oxygen Monitor Specification

- Classification

- IP 65

- Accuracy

- 0.5 %

- Humidity

- < 85% RH

- Sensor

- EC

- Display

- Graphics

- Operating Temperature

- -20 to 55 Celsius (oC)

- Usage

- Industrial

- Temperature

- 15 Celsius (oC)

- Material

- ABS plastic

- Color

- grey

- Power Supply

- 3.7V rechargable battery

- Product Type

- Handheld

- Response Time

- 10 Seconds

- Weight

- 250 Grams (g)

Industrial Oxygen Monitor Trade Information

- Minimum Order Quantity

- 1 Pack

- FOB Port

- Mumbai

- Supply Ability

- 50 Packs Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal packing with thermocol

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Industrial Oxygen Monitor

Features:-

- Excellent performance.

- Reliable operation.

- Less power consumption.

Specification:-

- Measurement Range: 0-25% V/V

- Sensor: EC

- Resolution: 0.1% V/V

- Sampling : Diffusion,Optional: Auto Suction Pump

High-Precision Monitoring for Industrial Environments

Equipped with advanced microcontroller technology, this oxygen monitor provides fast and precise oxygen level detection, helping protect workers and facilities. Its robust design ensures continuous operation in harsh conditions, from high humidity to extreme temperatures, making it indispensable in diverse industrial sectors.

Reliable and Durable Build

Constructed from tough ABS plastic and rated IP65, this monitor withstands exposure to dust and moisture. Its lightweight form factor, weighing only 0.6 kg (500 g), allows for easy installation and portability in any industrial setup, ensuring seamless integration into safety protocols.

FAQs of Industrial Oxygen Monitor:

Q: How is the Industrial Oxygen Monitor installed and used in an industrial setting?

A: The monitor can be easily mounted in your facility thanks to its compact and lightweight design. Simply connect it to a 3.7 V DC power supply, and its microcontroller-based system will automatically start monitoring oxygen levels. For optimal results, place the device in areas where continuous oxygen measurement is necessary.Q: What processes does the monitor support and how does it enhance safety?

A: This oxygen monitor supports various industrial processes where maintaining precise oxygen levels is critical, such as manufacturing, chemical processing, and confined space entry. It helps prevent hazardous situations by continuously alerting users to unsafe oxygen concentrations, supporting health and safety compliance.Q: When should I perform maintenance on the Industrial Oxygen Monitor?

A: Regular maintenance intervals depend on your operational environment, but generally, it is advisable to inspect and clean the monitor every six months. Periodic calibration is recommended to ensure continued accuracy, particularly in high-dust or humid environments.Q: Where can the device be used considering its temperature and humidity ratings?

A: The monitor is versatile and can function reliably at temperatures ranging from -5C to 55C and humidity levels from 095% RH. Its IP65 classification ensures it performs well in environments exposed to dust, water, and varying weather conditions, making it ideal for both indoor and outdoor industrial locations.Q: What are the main benefits of using this oxygen monitor in industrial applications?

A: The primary benefits include accurate real-time oxygen monitoring, enhanced safety for personnel, and compliance with industrial safety standards. Its durable, portable build and ease of integration make it a cost-effective solution for ongoing oxygen level management in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Portable Gas Detector Category

CO Gas leak Monitor

Price 20500 INR / Pack

Minimum Order Quantity : 1 Pack

Temperature : 15 Celsius (oC)

Power Supply : 3.7V Lithium battery

Machine Weight : 0.5 Kilograms (kg)

Usage : Industrial

Toxic Gas Detector

Price 68500 INR / Set

Minimum Order Quantity : 1 Set

Temperature : 5 to 55 Celsius (oC)

Power Supply : 3.7 V

Machine Weight : 0.6 Kilograms (kg)

Usage : Industrial

Chlorine Gas Leak Monitor

Price 26500 INR / Set

Minimum Order Quantity : 1 Set

Temperature : 15 Celsius (oC)

Power Supply : Lithium rechargeable

Machine Weight : 0.6 Kilograms (kg)

Usage : Industrial

Confined Space Oxygen Gas Analyzer

Price 30500 INR / Piece

Minimum Order Quantity : 1 Piece

Temperature : 20 to 55 Celsius (oC)

Power Supply : 3.7 V

Machine Weight : 0.3 Kilograms (kg)

Usage : Industrial

Send Inquiry

Send Inquiry