- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

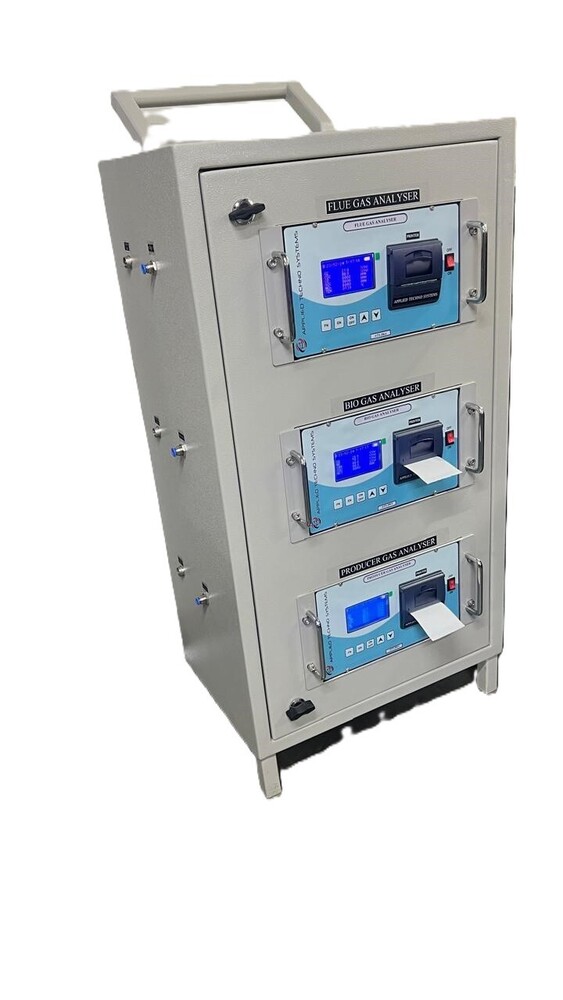

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

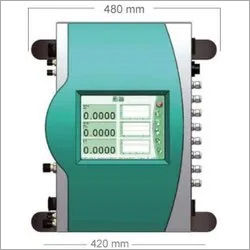

Online Flue Gas Analyzer

Price 850000 INR/ Unit

Online Flue Gas Analyzer Specification

- Temperature Range

- 0-250 Celsius (oC)

- Sensor Type

- EC & NDIR

- Resolution

- 0.01% for all gases

- Usage

- Monitoring & Analysing

- Power Supply

- 230 VAC 50 Hz

- Product Type

- Analyser

Online Flue Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Unit

- Packaging Details

- As Per Customer Requirement

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About Online Flue Gas Analyzer

| User defined fuels | Suitable for all fuels |

| can measure | O2, CO, CO2, SOx, NOx, HC & Temperature |

| Line Filter | Ceramic filter |

| Probe Length | 3 Meters |

| Measured Value | 0-10000 PPM |

| Hose length | One Meter |

| Make | APPLIED TECHNO SYSTEMS |

| Country of Origin | Made in India |

Advanced Technology for Accurate Gas Analysis

Utilizing EC and NDIR sensor technologies, the Online Flue Gas Analyzer delivers precise measurement results. Its high resolution of 0.01% enables detection of trace levels, essential for process optimization and environmental compliance. The analyzers robust construction supports reliable operation in temperature ranges from 0 to 250C.

Comprehensive Support and Service

From installation to after-sales support, our team assists customers throughout the analyzers lifecycle. We provide guidance on setup, calibration, data interpretation, and ongoing maintenance to ensure accuracy and durability, meeting the safety and regulatory requirements of Indian industries.

FAQs of Online Flue Gas Analyzer:

Q: How does the Online Flue Gas Analyzer provide accurate gas measurements?

A: The analyzer uses advanced EC (Electrochemical) and NDIR (Non-Dispersive Infrared) sensor types, which offer high precision and selectivity for various gases. With a resolution of 0.01%, it detects even minor fluctuations in gas concentrations, ensuring reliable monitoring results.Q: What are the main applications and industries for this flue gas analyzer?

A: It is widely used in industries such as power generation, cement, steel, petrochemical, and environmental monitoring. Typical applications include continuous emission monitoring, combustion process optimization, and compliance with air quality regulations.Q: When should the analyzer be calibrated or serviced?

A: Routine calibration is recommended as per the manufacturers guidelinesusually every 6 to 12 months, depending on usage and operating conditions. Regular maintenance ensures sustained accuracy and prolongs the lifespan of the sensors and electronics.Q: Where can the analyzer be installed for optimal performance?

A: Install the analyzer at points where flue gases are accessible, such as chimneys, exhaust ducts, or process stacks. Proper installation enhances measurement reliability and ensures representative sampling of gases within the 0-250C temperature range.Q: What is the process for setting up the Online Flue Gas Analyzer?

A: Setup involves mounting the device at the sampling location, connecting to a standard 230 VAC, 50 Hz power supply, configuring sensor parameters, and performing initial calibration. Detailed instructions and support are provided to ensure quick and accurate deployment.Q: How does using this analyzer benefit industrial operations?

A: By delivering real-time and precise gas measurements, the analyzer helps industries optimize combustion processes, reduce emissions, comply with legal standards, and improve energy efficiency. This leads to cost savings and minimizes environmental impact.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Effluent Monitoring Systems Category

Water Quality Monitoring System

Price 855000 INR / Unit

Minimum Order Quantity : 1 Unit

Display Type : Other, Digital LCD

Power Supply : 220V AC, 50Hz

Material : Industrial Grade Plastic & Metal

High-Accuracy Gas Measurement Systems

Price 78500 INR / Unit

Minimum Order Quantity : 1 Unit

Display Type : Other

Power Supply : 3.7 V DC Long Life Lithium Rechargeable Battery

Usage : Monitoring & Analysing

Effluent Monitoring Systems

Price 685500.00 INR / Set

Minimum Order Quantity : 1 Set

Display Type : Digital Only

Power Supply : 230 V AC

Usage : water quality monitoring

Continuous Stack Emission Monitor Systems

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Display Type : Digital Only

Power Supply : 200 to 240V a.c, 5060 Hz

Usage : Monitoring

Material : Metal

Send Inquiry

Send Inquiry