- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

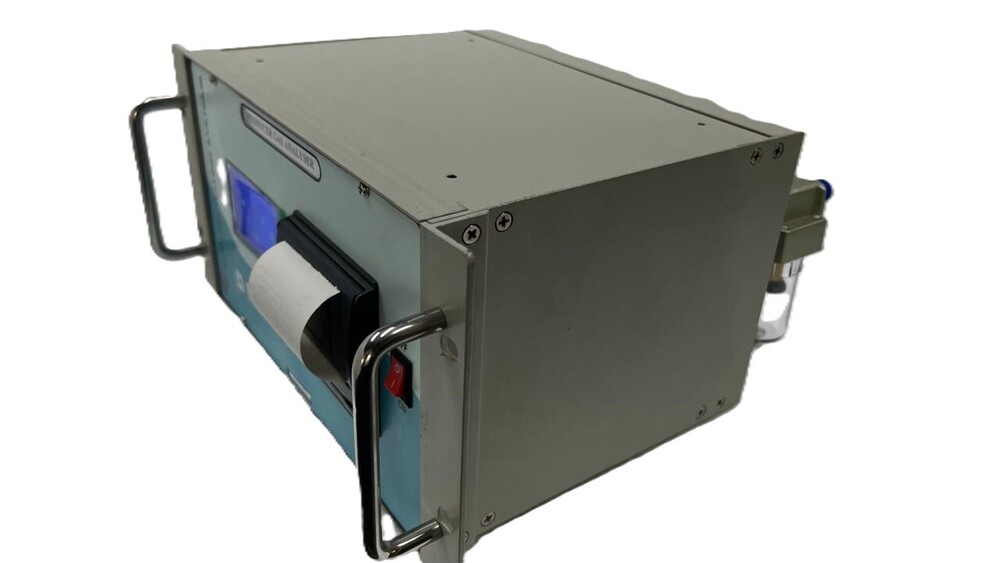

Online Hydrogen Purity Gas Analyzer

Price 295500 INR/ Unit

Online Hydrogen Purity Gas Analyzer Specification

- Humidity

- < 85%RH

- Resolution

- 0.01%

- Features

- In Built Suction Pump

- Temperature

- 15 Celsius (oC)

- Response Time

- less than 10 Seconds

- Usage

- Industrial

- Voltage

- 230 Volt (v)

- Power Supply

- Electric

- Dimension (L*W*H)

- 200 X 120 X 185 Millimeter (mm)

- Application

- Purity Analyser

Online Hydrogen Purity Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 4 Units Per Month

- Delivery Time

- 2 Week

- Packaging Details

- As Per Customer Requirement

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About Online Hydrogen Purity Gas Analyzer

The ATS 202A Portable Hydrogen Purity Analyzer and Purge Gas analyzer have been design especially for cylindrical and power station to check the Hydrogen Purity. The Analyzer is supplied in robust and reliable construction having Li-IONE rechargeable battery with 6 Hour of continuous operation. The integral Pump, Needle valve and Flow meter are used to control the sample through the analyzer during the monitoring of alternator gases. Features: Simple Low Cost maintenance Microcontroller based embedded intelligent

Specification:

- Principle Thermal Conductivity and NDIR (Non dispersive Infrared )

- Range %V/V Resolution 0.1 Unit or 1 Unit (Application based) Sampling Method Auto Suction or Direct Plug In

- Display 128 X 64 Graphics LCD

- Alarm Two Levels Low High Visual and Audible

- Power Source Built in Lithium Rechargeable battery

- Accuracy /2%

- Response Time Data Storage 5000 or 10000

- Computer Interface RS 232, USB,RS485

- Sensor Life 4-5 Years

- Operating Time 6 8 hours

- Environmental Temperature 15 degree Celsius

- Humidity Atmosphere Pressure 86- 106Kpa

- Housing High Impact Plastic

- Dimension in mm 200 (W) X 120 (H) X 185(D)

- Weight 1.5 KG

- Warranty One Year

Application:

- Hydrogen Cooled Alternators Turbine

- Hydrogen Analysis MAP (Food Gas Packaging)

- Gasification Syngas

- Metal Heat Treatment Plant

- Laboratories Institutions Treatment

- Process Chemical Industries

- Petrochemical Pharmaceutical Industries.

Advanced Purity Measurement Technology

This hydrogen purity analyzer incorporates the latest in analytical technology, designed to ensure precise and rapid assessment of gas samples. Its high-resolution capability enables detection of minute variations in hydrogen purity, making it a preferred choice for industries where consistency and accuracy are paramount.

Compact Design with Seamless Integration

Measuring just 200 x 120 x 185 mm, this compact analyzer is ideal for installations with limited space. The in-built suction pump allows effortless sample intake, while the sturdy design ensures durability in demanding industrial environments.

High Performance and Swift Response

With a response time of less than 10 seconds and a resolution down to 0.01%, the analyzer supports real-time monitoring and immediate feedback. This efficiency enhances operational productivity and assures top-tier quality control within multiple industrial applications.

FAQs of Online Hydrogen Purity Gas Analyzer:

Q: How does the Online Hydrogen Purity Gas Analyzer function in industrial environments?

A: The analyzer operates by extracting gas samples using its in-built suction pump, measuring their purity with high precision. Its electric-powered system and rapid response time help provide accurate readings, making it suitable for continuous monitoring in industrial settings.Q: What is the benefit of using an analyzer with a 0.01% resolution?

A: A 0.01% resolution allows the device to detect very small fluctuations in hydrogen purity, ensuring stringent quality control and reliable performance in critical industrial processes.Q: When should the analyzer be calibrated or serviced?

A: Its recommended to calibrate and service the analyzer periodically as per the manufacturers guidelines or after prolonged continuous usage, ensuring sustained accuracy and dependable results.Q: Where can this hydrogen gas analyzer be installed?

A: Due to its compact dimensions and robust design, the analyzer can be installed in various industrial environments across India, especially where space is limited and rapid purity analysis is essential.Q: What is the typical process for using this purity analyzer?

A: To use the analyzer, connect it to a 230 Volt power supply, ensure operating conditions (15C and <85% RH), initiate the sample suction, and let the device analyze the hydrogen purity. The user will receive results in less than ten seconds.Q: How does the in-built suction pump affect the analyzers performance?

A: The in-built suction pump ensures consistent and automatic sampling of gas, minimizing manual intervention and contributing to more reliable and efficient analysis results.Q: What are the main usage applications of this purity analyzer?

A: This analyzer is primarily used for industrial applications that require precise purity analysis of hydrogen gas, aiding exporters, importers, manufacturers, service providers, and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydrogen Purity Analyzer Category

Hydrogen Purity Analyzer

Price 118500.00 INR / Pack

Minimum Order Quantity : 1 Pack

Dimension (L*W*H) : 200 X 120 X 185 Millimeter (mm)

Material : Aluminum

Application : TO check the Purity

Gas Pressure : 1.5 Bar

Send Inquiry

Send Inquiry