- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

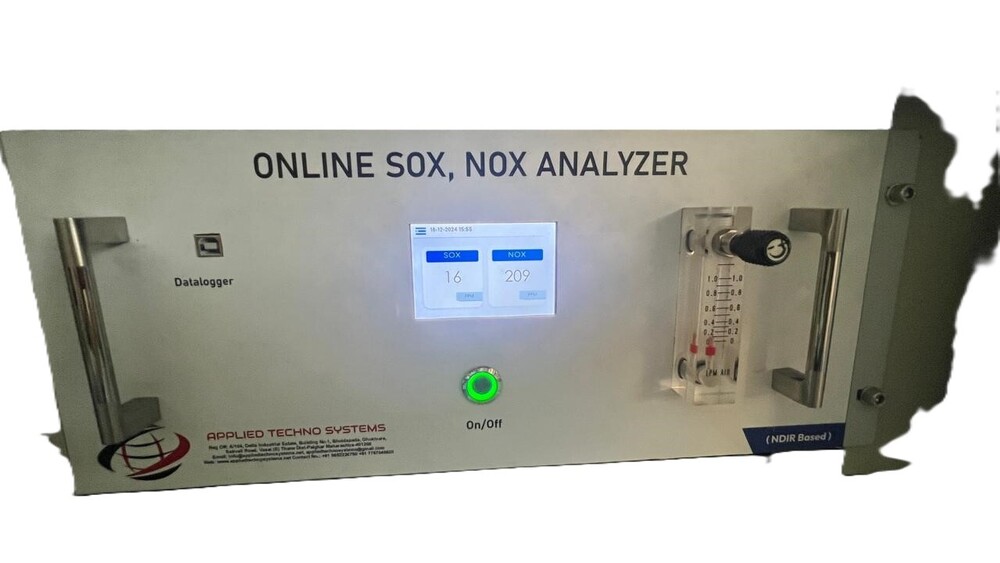

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Oxygen Gas Analyser

Price 19500 INR/ Pack

Oxygen Gas Analyser Specification

- Humidity

- < 85%RH

- Temperature

- 15 Celsius (oC)

- Usage

- Industrial

- Material

- ABS Plastic

- Power Supply

- Electric

- Accuracy

- +2 %

Oxygen Gas Analyser Trade Information

- Minimum Order Quantity

- 1 Pack

- FOB Port

- Mumbai

- Supply Ability

- 50 Packs Per Week

- Delivery Time

- 1-2 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal packing with thermocol

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- Main Domestic Market

- All India

About Oxygen Gas Analyser

The ATS -208A oxygen analysers have numerous applications in processes requiring the precise measurement of oxygen level. In ppm or % levels, safe areas or hazardous ones, in various process conditions and in differing backgrounds there is a ATS 208A configuration right for your needs. Options include a choice of outputs, AC or DC versions, alternative oxygen cells or sample conditioning.

Oxygen is measured in a wide variety of processes, to confirm its presence or absence. The most common application however is measuring oxygen as an 'impurity' in other gases, e.g. nitrogen generators. Oxygen is required in aerobic processes and also in situations that require user intervention, e.g. to ensure that it is safe to enter a chamber for maintenance work. Some processes will only run efficiently in the absence of oxygen, e.g. furnace atmospheres; others just require a low level of oxygen for safety reasons, e.g. inert gas blanketing.

Different electrochemical cells are available to suit the application. The standard A cell has a broad range from high ppm to 50% oxygen. The cell is designed for accuracy at low ppm levels; it will also work at % levels (with a shorter lifetime). The cell is designed for use in % levels of oxygen in the presence of mildly acidic gases, e.g. carbon dioxide, while the cell is perfect for low ppm oxygen applications where hydrogen is present. Applied will be pleased to advise on which cell is most suitable for an application.

A choice of configuration is available. The most convenient and economic is a standard analyser with the cell mounted on the rear. Alternatively, there is remote sensor housing complete with flowmeter and valve. Where cable lengths and/or hazardous area conditions are an issue, the transmitter can be located in the sensor housing.

Different sample conditioning systems are available, standard or bespoke, according to the process conditions. Filters, pumps and regulators can all be incorporated to deliver the sample in the correct condition. Bypass flow systems enable longer distances from process to analyser to be achieved. Applied engineers are ready to recommend the right system for you on receipt of the full gas stream specification.

For hazardous area barrier to the electronics unit in the safe area. Alternatively the electronics unit can be supplied in an Explosion proof enclosure.applications the sensor may be mounted remotely in the hazardous area and safely connected via an zener

Features

- Microcontroller based embedded intelligent instruments

- Long Life Electrochemical sensor

- Single 320 X 240 Graphics LCD Display

- Proven technology from gas analyser experts

- ppm or % O2 levels

- Hazardous area options

- Choice of cells for different applications

- Remote or integral sensor

- Choice of sample systems

- Applications

- Nitrogen generators

- Inert gas systems

- Air separation

- Furnace atmospheres

- Biogas

- Gloveboxes

- Gasification

- Packaging

High Performance Under Varied Conditions

Built with ABS plastic and engineered for consistent results, the oxygen gas analyser functions optimally at 15C and humidity below 85%. Its electric power supply ensures stable operation, making it suitable for a range of industrial environments. This device supports critical safety and process control applications, adapting quickly to changing site requirements.

Accurate Readings for Industrial Safety

The analyser provides oxygen measurement accuracy within 2%, enabling effective monitoring in professional settings. Designed for easy integration into existing systems, it helps maintain workplace safety standards and improves operational decision-making. The robust design contributes to reliable function across diverse atmospheric conditions.

FAQs of Oxygen Gas Analyser:

Q: How is the Oxygen Gas Analyser installed in an industrial environment?

A: The Oxygen Gas Analyser is typically installed near process areas where oxygen monitoring is essential. It requires an electric power connection and should be placed in locations where humidity is below 85% and the ambient temperature is around 15C to ensure optimal performance.Q: What materials are used in the construction of this analyser?

A: Our Oxygen Gas Analyser is constructed with high-grade ABS plastic, which offers excellent durability, resistance to corrosion, and a lightweight form factor for easy handling and installation.Q: When should this Oxygen Gas Analyser be calibrated?

A: We recommend calibrating the analyser at regular intervals, ideally every 6 to 12 months, depending on usage frequency and environmental factors, to maintain its stated accuracy of 2%.Q: Where can your company export and supply Oxygen Gas Analysers?

A: As an exporter, importer, manufacturer, and supplier based in India, we supply Oxygen Gas Analysers to clients globally, with particular expertise in fulfilling orders across industrial sectors throughout Asia, the Middle East, Africa, and Europe.Q: What is the process for using this analyser in industrial monitoring?

A: To use the Oxygen Gas Analyser, connect it to the electric power supply, configure the device according to the manufacturers guidelines, and position it in the designated area to begin real-time oxygen level monitoring. Regular maintenance ensures consistent accuracy.Q: How does using this analyser benefit industrial operations?

A: Employing the Oxygen Gas Analyser ensures precise oxygen measurement, assisting in safety compliance and process optimization. This helps prevent hazardous conditions, increases operational efficiency, and supports regulatory requirements for workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Gas Measurement Devices

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Rechargeable Battery With Charger

ATS Portable Biogas Analyzer Model ATS 201A

Price 245500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

Online SO2 Analyzer

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Hospital

Power Supply : Electric

Material : MS

Portable Emission analyzer

Price 158000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Material : Aluminium

Voltage : 230 Volt (v)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese