- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

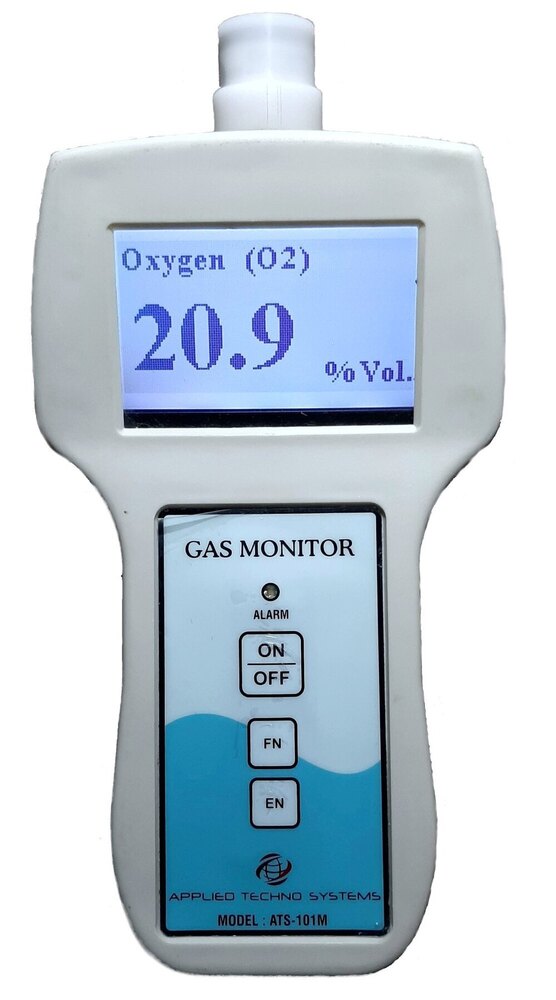

Oxygen Gas Detector

Price 32500 INR/ Unit

Oxygen Gas Detector Specification

- Voltage

- 110-215 Volt (v)

- Usage

- Industrial

- Hardness

- Yes

- Material

- MS

- Operate Method

- Manual

- Power Supply

- Manual

- Product Type

- Oxygen Gas Detector

Oxygen Gas Detector Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 7 Days

About Oxygen Gas Detector

Keeping track with the market development, we are engaged in offering our clients with a wide collection of Oxygen Gas Sensor. It is used for the Detection of combustible, toxic Gases and Oxygen. The offered sensor is meticulously tested on different quality parameters and is extensively demanded in various industries. Provided sensor is manufactured by utilizing best quality raw material and advanced technology. In line with industry standard, we provide the entire range in various customized options and at affordable prices.

Features:

- Precision-designed

- Superior performance

- Reliable operations

Applications:

- Environmental Monitoring

- Area Monitoring

- Pulp Paper

- Leak Detection Monitoring

- Chemical Plants

- Refineries/Petrochemical

- Hazardous Area

- Water/West water Treatment

- Fire Services

- Mine

Other Details:

- Detection of combustible, toxic Gases and Oxygen

- Non-intrusive calibration

- RED LED Display

- Smart sensors

- Programmable relays

- 2-wire, 3-wire, ModBus

- Flame proof Junction Box

- Available in stainless steel

- Available in wireless version

- Flame proof Junction Box Approval CCOE CMRI.

Comprehensive Industrial Safety

The Oxygen Gas Detector is ideal for safeguarding industrial environments such as manufacturing plants, laboratories, and processing units. Its durable MS construction ensures long-term performance, while manual operation provides direct user control. This device is well-suited to industries requiring strict environmental monitoring to maintain operational safety.

Flexible Power Compatibility

With an operational voltage range from 110 to 215 volts, this detector is compatible with most industrial power supplies found in India and internationally. The flexibility in voltage ensures easy integration, regardless of the installation location, making it a versatile choice for diverse operational settings.

Reliable Performance in Hazardous Conditions

Manual power supply and operation mean this oxygen detector doesnt rely on automated systems, offering reliable performance even in power fluctuations or hazardous industrial scenarios. Its sturdy build and tested hardness rating guarantee longevity and resistance to harsh working environments.

FAQs of Oxygen Gas Detector:

Q: How does the Oxygen Gas Detector function in industrial environments?

A: The detector continuously monitors the oxygen concentration in surrounding air, alerting personnel if levels deviate from safe thresholds. Its manual operation allows users to manage its performance directly, enhancing safety in critical situations.Q: What are the main benefits of using a manually operated oxygen gas detector?

A: Manual operation ensures greater control over the device, making it reliable in areas with unstable power or where automated systems might fail. Additionally, its robust MS material enhances durability in demanding industrial settings.Q: When should the Oxygen Gas Detector be installed within a facility?

A: It should be installed in any environment where oxygen level fluctuations could cause operational or health risks, such as confined spaces, manufacturing plants, or laboratories. Early installation helps prevent exposure to hazardous atmospheres.Q: Where can this oxygen detector be utilized?

A: This device is suitable for a broad range of industries across India, including chemical processing, pharmaceuticals, metal works, and safety compliance in confined spaces, owing to its voltage flexibility and sturdy build.Q: What is the process for maintaining the Oxygen Gas Detector?

A: Routine maintenance involves periodic calibration and functional testing to ensure accurate readings. Since it is manually powered and operated, inspections for mechanical integrity and cleanliness of sensors are also recommended.Q: How is the detector powered and why is a manual power supply advantageous?

A: Powered manually within a 110215 V voltage range, this detector does not depend on automated power sources, making it suitable for locations where electricity reliability is a concern, providing consistent operation during outages.Q: What advantages does the mild steel (MS) material offer?

A: The use of MS ensures the detector is hard, robust, and resistant to physical damage and corrosion, increasing its service life even in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Detector Category

Confined Space Gas Monitor

Price 58000.0 INR / Number

Minimum Order Quantity : 1 Number

Features : High Quality

Usage : Industrial

Display Type : Digital

Application : industrial

Portable H2S Gas Detector

Price 32500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Good Quality

Usage : Industrial

Display Type : Graphic

Application : Gas detect

Portable Multi Gas Monitor Model ATS 103M

Price 72500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Good Quality

Usage : Industrial

Display Type : LED

Application : Industrial

Portable Combustible Gas Leak Detector Model ATS 101M

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Robust ABS housing, Highly sensitive sensor, Flexible gooseneck probe, Audible buzzer, Visual LED alarm, Low battery indication

Usage : Leak detection in residential, commercial, and industrial sites

Display Type : Large LED bar graph and digital display

Application : Detection of combustible gas leaks (Methane, Propane, LPG, Natural Gas, Hydrogen, etc.)

Send Inquiry

Send Inquiry