- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

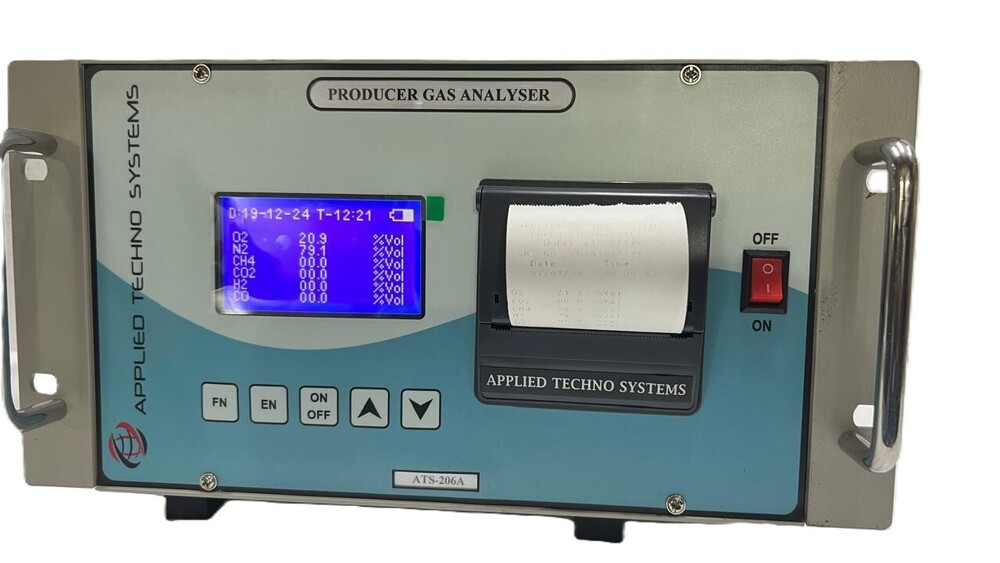

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Stack Gas Monitoring

Price 158000 INR/ Number

Stack Gas Monitoring Specification

- Power Supply

- Electric

- Usage

- Industrial

- Material

- Aluminium

- Color

- Grey

- Temperature

- -20 to +60 Celsius (oC)

- Humidity

- 0-95% RH

About Stack Gas Monitoring

Measurement Parameters

- Gases: CO, CO, O, NO, NO, SO, HS

- Range: Adjustable based on application; typically measured in parts per million (ppm) or percentage

- Resolution: 0.1 ppm to 1 ppm (varies by gas type)

- Accuracy: 2-5% of reading or better, depending on gas type

- Response Time: 10-30 seconds (depending on the gas and sensor type)

Sensor Types

- Electrochemical: Commonly used for CO, O, and NOx

- Infrared (IR): Used for CO and CH

- Optical / Laser: For high-accuracy measurements of gases like CO

- Paramagnetic: Often used for O

Physical and Environmental Specifications

- Operating Temperature: -10 to +50C (some models support extreme temperatures)

- Storage Temperature: -20 to +60C

- Humidity Range: 0-95% RH, non-condensing

- Pressure Range: Can typically measure up to 500 hPa or higher

Display and Interface

- Display: LCD or touchscreen with backlight

- Data Logging: Internal memory for 1,000+ measurements; some models include SD card support

- Connectivity: USB, Bluetooth, or Wi-Fi for data transfer

- Real-Time Data Display: Option to view data graphically or as raw values

Power and Battery

- Battery Type: Rechargeable Lithium-ion, with backup options

- Battery Life: 6-10 hours, depending on usage and model

- Charging Time: 2-4 hours

Calibration and Maintenance

- Calibration: Factory-calibrated, with user calibration options available

- Maintenance: Periodic sensor replacement and calibration recommended, usually annually

- Self-diagnosis: Built-in system diagnostics for sensor and system health

Certification and Compliance

- Compliance: EPA, EN, ISO standards for emissions

- Safety Certifications: ATEX, CE, or other certifications for hazardous environments (optional)

- Environmental Regulations: Meets regional emission standards

Rugged Aluminium Build for Industrial Demands

Our stack gas monitoring solutions feature robust aluminium bodies, ensuring long-lasting performance even in challenging industrial settings. This material resists corrosion and maintains structural integrity in varied temperatures and high humidity, making it suitable for continuous operation in factories and plants.

Wide Operational Range for Versatile Applications

Operating reliably between -20C and +60C, our stack gas monitors adapt to various climates and process conditions. With electric power supply and resilience up to 95% humidity, these units can be installed in diverse locations without compromising accuracy or efficiency.

FAQs of Stack Gas Monitoring:

Q: How does stack gas monitoring benefit industrial operations?

A: Stack gas monitoring helps industries comply with environmental regulations by detecting and measuring emissions. This ensures safe air quality and supports process optimization, reducing potential penalties and improving worker safety.Q: What materials are used in the stack gas monitoring system?

A: The system uses high-grade aluminium, providing durability and resistance to harsh industrial conditions, along with a grey finish for a sleek, professional look.Q: When should businesses implement stack gas monitoring solutions?

A: It is recommended to install stack gas monitors whenever venting combustion gases or pollutants, especially in industries subject to emission regulations or aiming to strengthen environmental stewardship.Q: Where can these stack gas monitors be installed?

A: These devices are suitable for a range of industrial sites, including manufacturing plants, power stations, and chemical processing facilities throughout India, both indoors and outdoors where specified temperature and humidity limits are maintained.Q: What is the process for operating the stack gas monitoring system?

A: After installation at the designated site, the system is powered electrically and programmed according to process requirements. Regular calibration and maintenance help ensure precise and reliable readings.Q: How is humidity managed in these monitoring systems?

A: Designed to operate efficiently in environments with humidity levels up to 95% RH, these monitors incorporate sealing and protective features for stable performance in highly humid industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Industrial gas analyzer

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial, Petrochemical, Pharmaceutical, Environmental monitoring

Power Supply : AC 230V, 50/60 Hz

Online Producer Gas Analyzer

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Bio Gas/ Syn gas Analyzer

Price 195000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Material : Aluminium

Voltage : 220 Volt (v)

Confined Space Oxygen Gas Leak Monitor

Price 30000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Material : ABS Plastic

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry