- Dew Point Meters

- Gas Analysers

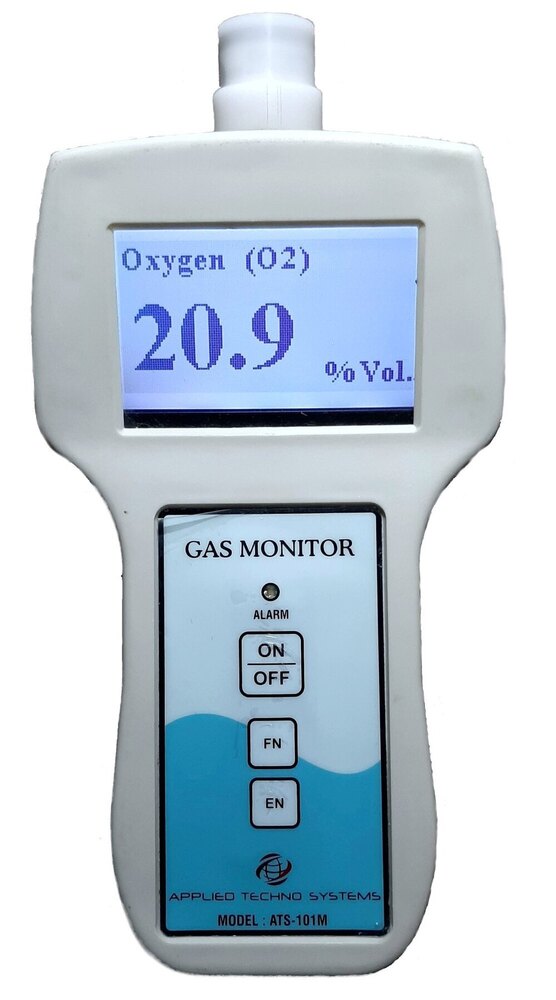

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

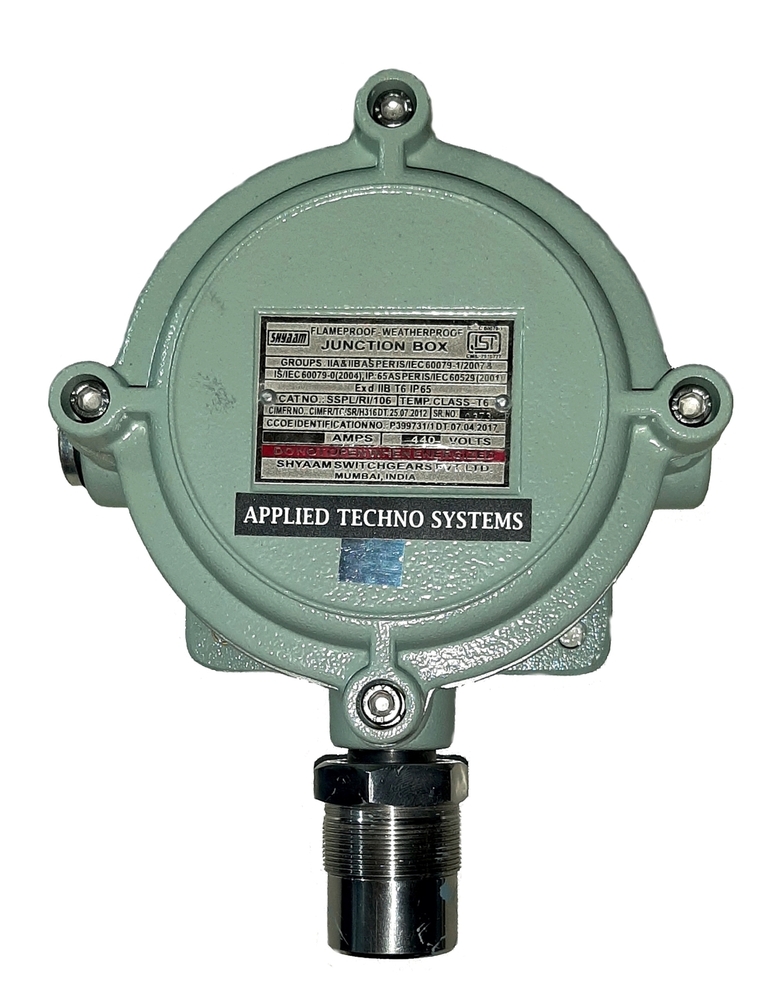

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Sulfur Dioxide SO2 Gas Detector

Price 72800 INR/ Unit

MOQ : 1 Unit

Sulfur Dioxide SO2 Gas Detector Specification

- Application

- Monitoring System

- Power Supply

- Rechargeable Battery With Charger

- Temperature

- 15 Celsius (oC)

- Usage

- Monitoring and Detection Systems

- Display Type

- Digital

- Accuracy

- +/- 2 %

- Humidity

- < 85%RH

- Product Type

- Monitor

Sulfur Dioxide SO2 Gas Detector Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 2 Units Per Week

- Delivery Time

- 3 Days

- Packaging Details

- As Per Customer Requirement

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About Sulfur Dioxide SO2 Gas Detector

The Sulfur Dioxide (SO2) Gas Detector stands out as an elite, top-drawer device designed for sought-after industrial environments. Engineered for potent performance, it ensures rapid and accurate detection with +/- 2% precision. Offering instant checkout and favorable discount opportunities, this product comes with a rechargeable battery and charger, extending operational time. Its digital display streamlines monitoring for power plants, chemical sites, and other sensitive zones. As a trusted exporter, importer, manufacturer, service provider, and supplier in India, we guarantee dependable detection systems for every safety need.

Versatile Monitoring for Critical Spaces

This SO2 Gas Detector is ideal for continuous monitoring and detection in industrial and commercial environments. Designed for usage in monitoring systems, it excels in areas such as power supply stations, manufacturing plants, and chemical facilities. Whether deployed for fixed or portable monitoring, it delivers reliable sulfur dioxide readings, helping maintain a safe working atmosphere in sensitive, high-risk locations with utmost efficacy.

Packaging, Supply Ability & Payment Flexibility

Packaging details for the Sulfur Dioxide Gas Detector ensure that shipped goods arrive intact and ready for use. Our robust supply ability guarantees timely fulfillment for bulk orders, supported by flexible payment terms adapted to your proposal amount and sale price agreements. Designed to give you comprehensive purchasing control, our processes ensure seamless transactions for both domestic and international clients.

Versatile Monitoring for Critical Spaces

This SO2 Gas Detector is ideal for continuous monitoring and detection in industrial and commercial environments. Designed for usage in monitoring systems, it excels in areas such as power supply stations, manufacturing plants, and chemical facilities. Whether deployed for fixed or portable monitoring, it delivers reliable sulfur dioxide readings, helping maintain a safe working atmosphere in sensitive, high-risk locations with utmost efficacy.

Packaging, Supply Ability & Payment Flexibility

Packaging details for the Sulfur Dioxide Gas Detector ensure that shipped goods arrive intact and ready for use. Our robust supply ability guarantees timely fulfillment for bulk orders, supported by flexible payment terms adapted to your proposal amount and sale price agreements. Designed to give you comprehensive purchasing control, our processes ensure seamless transactions for both domestic and international clients.

FAQs of Sulfur Dioxide SO2 Gas Detector:

Q: How is the Sulfur Dioxide SO2 Gas Detector used in monitoring systems?

A: The detector is integrated into onsite monitoring systems for continuous real-time measurement of sulfur dioxide levels, ensuring prompt alerts in case of dangerous concentrations.Q: What makes this SO2 Gas Detector sought-after for industrial safety?

A: Its potent accuracy, digital display, and rechargeable battery make it a top-drawer solution, especially favored for critical sites requiring reliable gas detection and prompt response.Q: Where can the SO2 Gas Detector be deployed effectively?

A: It is best suited for power stations, chemical plants, manufacturing zones, and other areas with potential sulfur dioxide emissions, safeguarding personnel and assets.Q: What is the process for instant checkout and order placement?

A: Customers can benefit from instant checkout via our online portal or direct inquiry. As exporter, importer, and supplier, we streamline ordering for fast, hassle-free procurement.Q: How does the rechargeable battery benefit usage in monitoring and detection systems?

A: The rechargeable battery delivers long-lasting operation, reducing downtime and maintenance needs in monitoring systems, thereby supporting continuous supervision in demanding environments.Q: What kind of packaging and shipment can buyers expect?

A: Shipped goods are carefully packaged to protect the detector and accessories, assuring safe and intact delivery to both domestic and international customers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gas Detector Category

ATS-101M Portable Gas Leak Detector/Monitor

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial & Safety

Power Supply : Lithium Battery / 220V Charger

Hand Held Ethylene Gas ( C2H4O) Detector Model ATS 101M

Price 58500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Material : ABS Plastic

Portable Single/Multi Gas Monitor ( Model Ats-103m )

Price 68000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Material : ABS Plastic

Voltage : 230 Volt (v)

Power Supply : Electric

Portable H2S Gas Detector

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry