- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

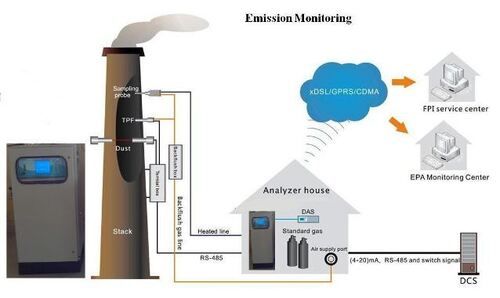

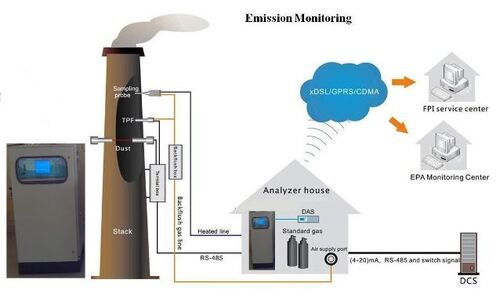

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

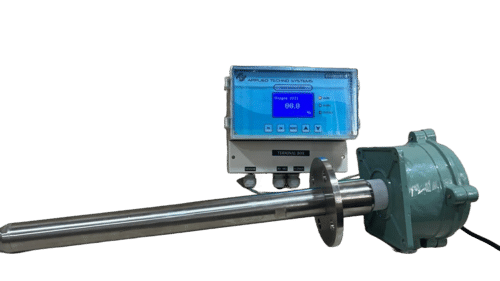

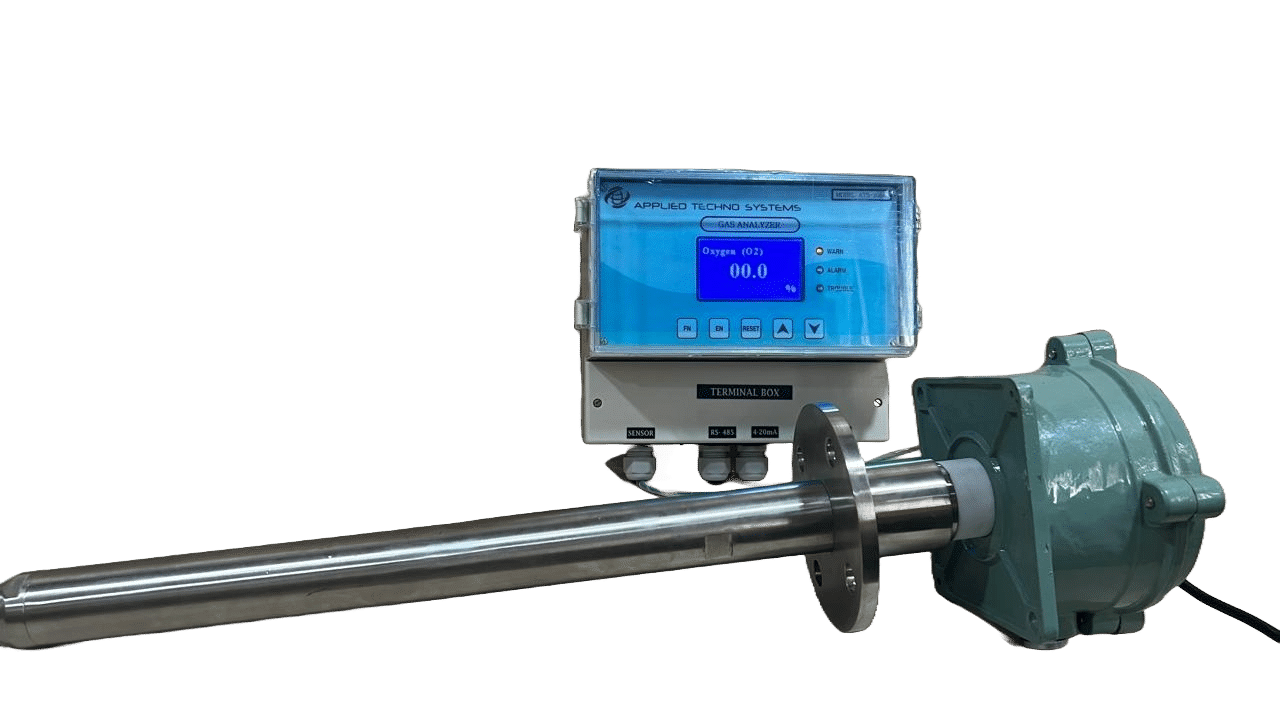

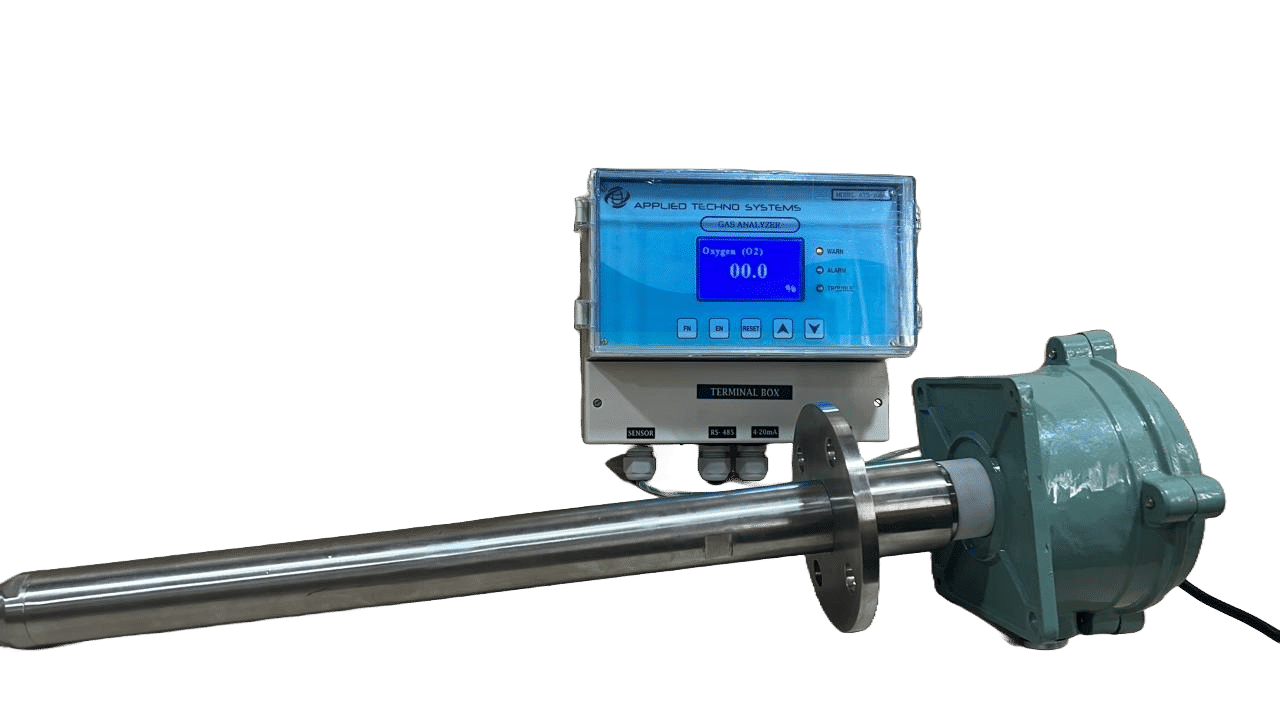

Zirconia oxygen sensor

Price 195000 INR/ Number

Zirconia oxygen sensor Specification

- Humidity

- 95%

- Product Type

- Zirconia oxygen sensor

- Power Supply

- Electric

- Material

- Mild Steel

- Color

- Grey

- Usage

- Industrial

About Zirconia oxygen sensor

- Zirconia Sensor Element: The core component is a zirconium dioxide (zirconia) ceramic, typically doped with yttria, that functions as a solid electrolyte. When exposed to high temperatures, zirconia allows oxygen ions to move through its lattice structure, generating a voltage that corresponds to the oxygen concentration.

- High Temperature Tolerance: These analyzers work effectively at high temperatures, often above 600C (1112F), making them suitable for environments like flue gas, combustion chambers, and kilns.

- In-Situ Installation: As an in-situ device, it measures directly within the gas flow. This design eliminates the need for sample extraction and conditioning, making it quicker to respond to changes in oxygen levels.

- Electrochemical Principle: Zirconia-based analyzers leverage the Nernst equation, which relates the EMF (voltage) generated across the zirconia electrolyte to the partial pressure of oxygen in the measured gas.

- Fast Response Time: Due to the direct measurement approach and high-temperature functionality, these analyzers offer a fast response time, critical for controlling combustion processes efficiently.

Applications

- Combustion Control: Used in power plants, cement kilns, steel manufacturing, and petrochemical industries to optimize combustion, reduce emissions, and improve fuel efficiency.

- Process Safety: Monitoring oxygen levels to prevent explosive mixtures or ensure safe operating conditions.

- Environmental Compliance: Helps in maintaining low oxygen levels to control NOx and CO emissions.

- Real-Time Measurement: Instantaneous data helps optimize processes.

- Low Maintenance: Limited or no need for gas sampling lines, reducing downtime.

- Durability: Designed for continuous operation in challenging industrial environments.

In-situ zirconia-based oxygen analyzers provide essential control and monitoring capabilities in various high-temperature industrial processes, ensuring both efficiency and safety.

Reliable Oxygen Monitoring for Industrial Needs

Engineered for versatility, the Zirconia oxygen sensor delivers accurate and continuous oxygen measurement even in humid conditions up to 95%. Its mild steel body guarantees durability amidst harsh industrial settings, facilitating uninterrupted monitoring and enhanced operational efficiency. Exported, imported, and supplied throughout India, this sensor supports both new installations and existing system upgrades.

Advanced Sensing Technology for Process Optimization

Utilizing advanced zirconia technology, this oxygen sensor provides rapid and reliable detection of oxygen concentration, vital for process control and compliance in industries. Its electric power supply ensures effortless integration into various systems. The grey, corrosion-resistant finish adds aesthetic value and longevity to the device while maintaining peak performance throughout its service life.

FAQs of Zirconia oxygen sensor:

Q: How does the Zirconia oxygen sensor operate in high humidity environments?

A: The Zirconia oxygen sensor is designed to function effectively in environments with humidity levels up to 95%. Its robust construction and material selection ensure it maintains accurate readings and reliable operation without being affected by moisture.Q: What are the main benefits of using this sensor in industrial applications?

A: This sensor provides precise oxygen monitoring essential for process optimization and safety. Its durability, resistance to corrosion, and ability to function in harsh conditions make it beneficial for industries seeking consistent and trustworthy performance.Q: When should the Zirconia oxygen sensor be installed or maintained in industrial operations?

A: Installation should be considered during system upgrades or new industrial setups requiring oxygen monitoring. Regular maintenance ensures sustained accuracy and longevity, typically recommended at intervals suggested by the manufacturer based on operational demands.Q: Where is the Zirconia oxygen sensor commonly used in India?

A: It is widely utilized across various industrial establishments throughout India, including chemical plants, manufacturing units, and process industries, wherever precise oxygen detection is critical for safe and efficient operations.Q: What is the process for integrating the oxygen sensor into existing industrial systems?

A: Integration involves connecting the sensor to the sites electric power supply and integrating with control and monitoring instruments. Suppliers and service providers in India assist with installation and provide guidance for optimal configuration.Q: How does zirconia technology enhance the sensors performance?

A: Zirconia technology allows for rapid and precise measurement of oxygen levels. The advanced ceramic material improves sensor response time, stability, and resistance to chemical and thermal stress, ensuring high accuracy over extended use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

insitu zirconia based oxygen analyzer

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Power Supply : Electric

Humidity : < 85%RH

Color : Silver

Stack Gas Analyzer

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Power Supply : 200 to 240V a.c, 5060 Hz

Humidity : < 85%RH

Stack Emission monitor continuous Emission Analyzer

Price 400000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Humidity : 85%RH

Color : Grey

Continuous Emission Monitoring System

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Humidity : 95% RH

Color : Grey

Send Inquiry

Send Inquiry