- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

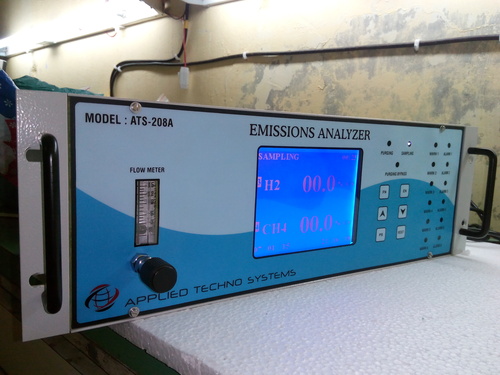

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Ammonia Gas Analyser

Price 225000 INR/ Unit

Ammonia Gas Analyser Specification

- Voltage

- 110-215 Volt (v)

- Operate Method

- Semi Automatic

- Display Type

- LED

- Material

- MS

- Mounting Type

- Handheld or tripod

- Automation Grade

- Semi-automatic

- Features

- Good Quality

- Usage

- Industrial

- Test Stroke

- Digital touch screen

- Control Mode

- Manual

Ammonia Gas Analyser Trade Information

- Minimum Order Quantity

- 1 Unit

- Delivery Time

- 7 Days

About Ammonia Gas Analyser

Ammonia Gas Analyser continuously monitors the concentration of Ammonia in PPM and other gases ranging from 100%V/V down to PPM level. Feature includes a duel wavelength sensor, Remote Sampling, Graphics LCD Display, adjustable level relay output for alarm and 4-20mA output for control purpose and minimal maintenance.

- Special gas sample Conditioning systems are used to clean and dry the gas sample for accurate and High performance operation. An Internal Pump draw gas sample into the sensor through a dust particle filter from an intake which can be located at distance up to 40 meter form the monitor.

- The Sensor and Electronic component are housed in tough aluminum housing.

Applications:

- Metal heat Treatment

- Boiler Systems

- Cement & Lime Manufacturer

- Combustion Process

- Hydrogen Cooled Alternators & Turbine

- Gasification & Syngas

- Pulp & Paper

- Metal Heat Treatment Plant

- Laboratories & Institutions

- Flame Treatment Process & Chemical Industries

- Petrochemical & Pharmaceutical Industries

Features:

- Microcontroller based embedded intelligent instruments

- Continuous Monitoring of CO2 ,CH4, CO, O2, SO2, NOX (NO NO2), H2, H2S, N2

- Duel wavelength Infra red sensor for Long terms accuracy and stability

- Long Life Electro chemical sensor

- Six Gas Analysis in Single Analyzer

- Multi Parameter Single 320 X 240 Graphics LCD Display

- Self diagnostic & Self integrity check

- RS 232/RS 485 and USB Computer Interface

- Excellent low level capability for NOX and SO2 Measurement

- For most of the application sample gas is cooled and dried inside the sampling conditioning systems to avoid the Heated Sample Line.

- Analog 4-20mA output for each gas

- Software solutions for Gas Analysis

- Web Based Real time data transfer with GSM/GPRS Technology

Advanced Detection for Industrial Needs

Designed for rigorous industrial environments, the Ammonia Gas Analyser delivers accurate and swift ammonia monitoring. The durable MS construction and semi-automatic operation make it reliable for daily use. The analysers flexible mounting options allow for handheld surveys or stable tripod positioning, optimizing user comfort during extended monitoring sessions.

User-Friendly Operation & Digital Display

Users benefit from the intuitive manual control and easy-to-navigate digital touch screen. The built-in LED display ensures readings are easily visible even in low-light conditions, reducing the risk of error and promoting efficiency during operation. These features make the analyser accessible for both experienced professionals and new operators.

FAQs of Ammonia Gas Analyser:

Q: How does the Ammonia Gas Analyser operate in industrial settings?

A: The analyser employs a semi-automatic process, allowing users to manually control sampling and testing sequences. It is well-suited for continuous or periodic monitoring of ammonia levels, providing clear results via an LED display and digital touch screen interface.Q: What materials are used in the construction of the Ammonia Gas Analyser?

A: The analyser is manufactured from high-quality mild steel (MS), offering robust protection against industrial wear and ensuring long-term durability in demanding work environments.Q: When should the Ammonia Gas Analyser be used?

A: This analyser should be used whenever there is a need to monitor ammonia gas concentrations, particularly in industrial facilities, laboratories, or during equipment maintenance where ammonia leaks may pose a risk.Q: Where can the analyser be mounted for use?

A: Operators can utilize the analyser as a handheld device for flexibility or mount it on a tripod for stable, stationary measurements, adapting to various site conditions and testing requirements.Q: What is the usage process for testing ammonia with this device?

A: To use, simply power the unit within the 110-215 Volt range, position the sampling probe, use the digital touch screen to initiate the test, and view the instant results on the LED display.Q: What are the primary benefits of using this Ammonia Gas Analyser?

A: Key benefits include high-quality construction, precise digital controls, dual mounting options, a user-friendly interface, and reliable performance, all contributing to enhanced safety and efficiency in ammonia monitoring tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Chlorine Gas Analayzer

Price 130500 INR / Pack

Minimum Order Quantity : 1 , , Pack

Usage : Industrial

Power Supply : Electric

Producer Gas Analyzer With Printer Model ATS 204A

Price 775000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

CO2 Gas Analyzer

Price 98500 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Power Supply : Electric

Material : Mild Steel

Combustion Gas Analyzer

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Material : Aluminium

Voltage : 230 Volt (v)

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese