- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

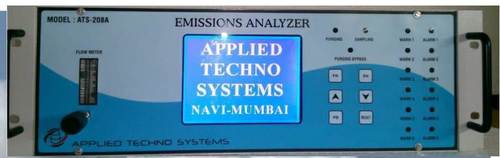

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

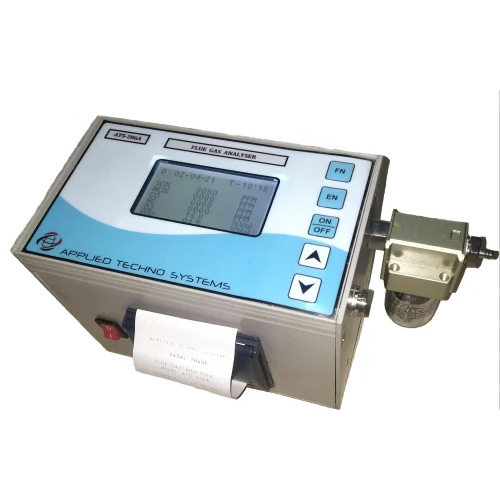

Combustion Analyzers

Price 158000 INR/ Number

Combustion Analyzers Specification

- Color

- Grey

- Usage

- Industrial

- Temperature

- -20 to 50 Celsius (oC)

- Voltage

- 230 Volt (v)

- Material

- Aluminium

- Power Supply

- Electric

- Product Type

- Combustion Analyzers

About Combustion Analyzers

Measurement Parameters

- Gas Components: Oxygen (O2), Carbon Dioxide (CO2), Carbon Monoxide (CO), Nitrogen Oxides (NOx), Sulfur Dioxide (SO2), and Hydrocarbons.

- Combustion Efficiency: Percentage of fuel converted to energy.

Measurement Range

- Specific concentration ranges for each gas (e.g., 0-21% for O2, 0-100% for CO2).

Accuracy and Precision

- Percent error for each measurement (e.g., ±0.1% for O2, ±1 ppm for CO).

- Calibration intervals.

Response Time

- Time taken for the analyzer to provide stable readings (e.g., seconds).

Operating Conditions

- Temperature range (e.g., -20°C to 50°C).

- Pressure range (e.g., atmospheric pressure).

- Humidity tolerance.

Sensor Technology

- Types of sensors used (e.g., electrochemical, infrared, paramagnetic).

Data Output

- Digital and/or analog outputs (e.g., 4-20 mA, RS-232, USB).

- Data logging capabilities for historical analysis.

Power Requirements

- Voltage and current specifications.

- Power consumption details.

User Interface

- Display type (e.g., LCD, touchscreen).

- Software features for data visualization and reporting.

Calibration and Maintenance

- Calibration procedure and frequency.

- Maintenance requirements (e.g., routine checks, cleaning).

Compliance Standards

- Adherence to industry standards (e.g., EPA, ISO).

- Certification (e.g., CE, UL).

Portability

- Weight and dimensions for portable models.

- Battery life and charging options if applicable.

- Initial purchase price.

- Operating and maintenance costs over time.

These specifications can help you choose a combustion analysis system tailored to your specific needs and applications. If you have a particular context in mind, I can refine this further!

Engineered Reliability for Industrial Applications

Manufactured from high-quality aluminium, our combustion analyzers are robust and corrosion-resistant. Their reliable performance, even under harsh conditions, ensures long-term use in a wide range of industrial settings. The temperature operating window from -20 to 50C makes them adaptable to variable climates across India and beyond.

Comprehensive Export, Import, and Service Solutions

We not only manufacture combustion analyzers but also manage export and import requirements, ensuring seamless procurement for clients globally. Our experienced team provides technical support, installation, and after-sales service, helping customers make the most of their analyzers.

FAQs of Combustion Analyzers:

Q: How is a combustion analyzer used in industrial settings?

A: A combustion analyzer is used to measure and analyze the combustion efficiency of industrial burners, furnaces, and boilers. By providing accurate data on oxygen, carbon monoxide, and other gases, it helps maintain optimal fuel efficiency and safety.Q: What benefits do aluminium-bodied combustion analyzers offer?

A: Aluminium construction makes these analyzers lightweight, corrosion-resistant, and durable, ensuring a longer service life even in challenging industrial environments. This translates to lower maintenance costs and consistent performance.Q: When should an industrial facility use a combustion analyzer?

A: Combustion analyzers should be used during routine maintenance, system troubleshooting, and regulatory compliance checks to ensure efficient and safe operation of combustion systems.Q: Where can these combustion analyzers be installed?

A: They can be installed in industrial settings such as power plants, manufacturing units, processing facilities, and any area where fuel-burning equipment is operated within the supported temperature range.Q: What is the process to procure these analyzers from your company in India?

A: Clients can contact us directly as we serve as exporter, importer, manufacturer, supplier, and service provider. We handle end-to-end solutions from consultation and purchase to installation and after-sales service.Q: How does the analyzers temperature range benefit industrial users?

A: The analyzers -20 to 50C operating range ensures functionality in both cold and hot environments, making it suitable for facilities across diverse climatic regions.Q: What advantages does an electric-powered analyzer operating on 230 volts provide?

A: An electric supply (230V) ensures stable power for precise measurements, while compatibility with standard voltage in India simplifies installation and operation in industrial facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Fixed Type Stack Monitoring System

Price 587800.00 INR / Set

Minimum Order Quantity : 1 Set

Usage : Online Continuous Emission Monitoring Systems

Material : Aluminum

Power Supply : Electric

Dimension (L*W*H) : 200 X 120 X 185 Millimeter (mm)

Flue Efficiency Gas Analyzer

Price 72500 INR / Pack

Minimum Order Quantity : 1 Pack

Usage : Industrial

Material : ABS plastic

Power Supply : Electric

Dimension (L*W*H) : 200 X 120 X 185 Millimeter (mm)

Flue Gas Analyzer

Price 42500 INR / Pack

Minimum Order Quantity : 1 Pack

Usage : stack, boiler, exhaust

Power Supply : Electric

Dimension (L*W*H) : 200 X 120 X 185 Millimeter (mm)

Chlorine Gas Analyzer

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Power Supply : Manual

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese