- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

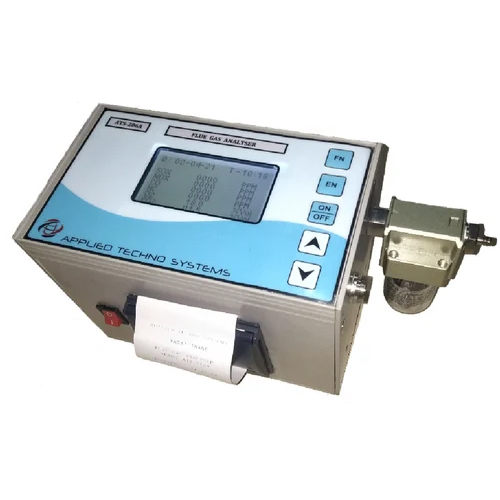

Flue Gas Analyser

Price 185000 INR/ Unit

Flue Gas Analyser Specification

- Mounting Type

- Handheld or tripod

- Voltage

- 110-215 Volt (v)

- Automation Grade

- Semi-automatic

- Hardness

- Yes

- Power Supply

- Electric

- Operate Method

- Semi Automatic

- Material

- MS

- Features

- Good Quality

- Usage

- Industrial

Flue Gas Analyser Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 7 Days

About Flue Gas Analyser

As per the variegated requirements of our clients, we are offering a broad collection of Flue Gas Analyser. This analyser is manufactured using exceptional quality components and advanced technology by our deft professionals. In order to make sure quality, this analyser is strictly tested on various parameters by our experts. Apart from this, remarkable quality and sturdy structure increase the demand of our offered range in the market.

Features:

- Rugged construction

- High functionality

- Easy to operate

Other Details:

- Microcontroller based embedded intelligent instruments

- Measured Up to 8 gases

- Long Life Zirconium sensor for Oxygen

- Multi Parameter Single Graphics LCD Display

- Self diagnostic Self integrity check

- Direct Plug In or Auto Suction Sampling

- Sampling Probe Up to 1600 Deg C

- Long Life Rechargeable Li-Ione Battery

- RS 232 and USB Computer Interface

- Software solutions for Flue Gas Analysis

Application:

- Metal heat Treatment

- Combustion Process

- Hydrogen Cooled Alternators Turbine

- Gasification Syngas

- Metal Heat Treatment Plant

- Laboratories Institutions

- Flame Treatment Process Chemical Industries

- Petrochemical Pharmaceutical Industrie

Specification:

- Principle Electrochemical, Zirconium, Thermal Conductivity and NDIR (Non dispersive Infrared)

- Range %V/V PPM

- Resolution 0.1 Unit or 1 Unit (Application based)

- Sampling Method Auto Suction or Direct Plug In

- Gas Sampling Probe Dia 8mm SS 316

- Display 128 X 64 Graphics LCD

- Alarm Visual and Audible

- Power Source Built in Lithium Rechargeable battery

- Accuracy /2%

- Response Time

- Data Storage 5000 or 10000

- Computer Interface RS 232, USB, RS485

- Sensor Life 4-5 Years

- Operating Time 6 -8 hours

- Environmental

- Temperature 15degree Celsius

- Humidity < 85%RH

- Atmosphere Pressure 86- 106Kpa

- Housing High Impact Plastic

- Dimension in mm 200 (W) X 120 (H) X 185(D)

- Weight 1.5 KG

- Warranty One Year

Versatile and Durable Design

Tailored for demanding industrial environments, this Flue Gas Analyser boasts a durable MS body. Its semi-automatic operation and option for handheld or tripod mounting provide flexibility for stationary or field measurements. The rugged construction ensures performance and longevity even in harsh settings, making it an optimal choice for reliable flue gas monitoring.

Streamlined Measurement and Compliance

Designed to deliver precise analysis, this analyser simplifies the process of monitoring flue gases in compliance with regulatory standards. Operating semi-automatically, it reduces user intervention and speeds up routine testing tasks. Industrial users benefit from real-time data, enabling faster decisions, process optimization, and safer operations.

FAQs of Flue Gas Analyser:

Q: How does the semi-automatic Flue Gas Analyser operate in industrial settings?

A: The semi-automatic Flue Gas Analyser functions by drawing samples of flue gas from industrial processes, using onboard sensors to detect key components. The device requires minimal manual input, making it efficient for routine monitoring, whether handheld or mounted on a tripod.Q: What benefits does this analyser provide for industrial users in India?

A: Industrial users gain advantages such as precise gas measurement, durable MS construction, and compliance support. It enhances safety, optimizes operational efficiency, and meets diverse industrial needs due to its adaptable power range and robust build.Q: When is it appropriate to use a handheld versus a tripod-mounted analyser?

A: A handheld configuration is ideal for mobile inspections or accessing tight spaces, while tripod mounting provides stability during longer measurement sessions or when high consistency is required. The dual mounting options accommodate various industrial monitoring scenarios.Q: Where can this Flue Gas Analyser be applied within an industrial facility?

A: This analyser can be deployed at boilers, furnaces, chimneys, and any industrial exhaust points where emission monitoring is vital. Its portable design enables use across multiple locations as required by operational protocols.Q: What is the process for using the analyser to obtain gas readings?

A: To use the analyser, connect it to the power supply (110-215V), position it at the gas sampling point, and initiate the semi-automatic sequence. The device then analyzes the flue gas and displays readings, which can be documented or exported as needed for regulatory or internal purposes.Q: How does the power supply rating benefit industrial users?

A: A voltage range of 110-215V ensures compatibility with varying industrial electric systems across different regions. This adaptability facilitates easy integration without extensive rewiring or modifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

NDIR Gas Analyser

Price 598500 INR / Set

Minimum Order Quantity : 1 Set

Usage : Industrial

Material : Aluminum

Voltage : 230 Volt (v)

Power Supply : Electric

Combustion Gas Analyzer

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Aluminium

Voltage : 230 Volt (v)

Power Supply : Electric

Sulphur Dioxide Gas Analyzer

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

Power Supply : Electric

Chlorine Gas Analyzer

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

Power Supply : Manual

Send Inquiry

Send Inquiry