- Dew Point Meters

- Gas Analysers

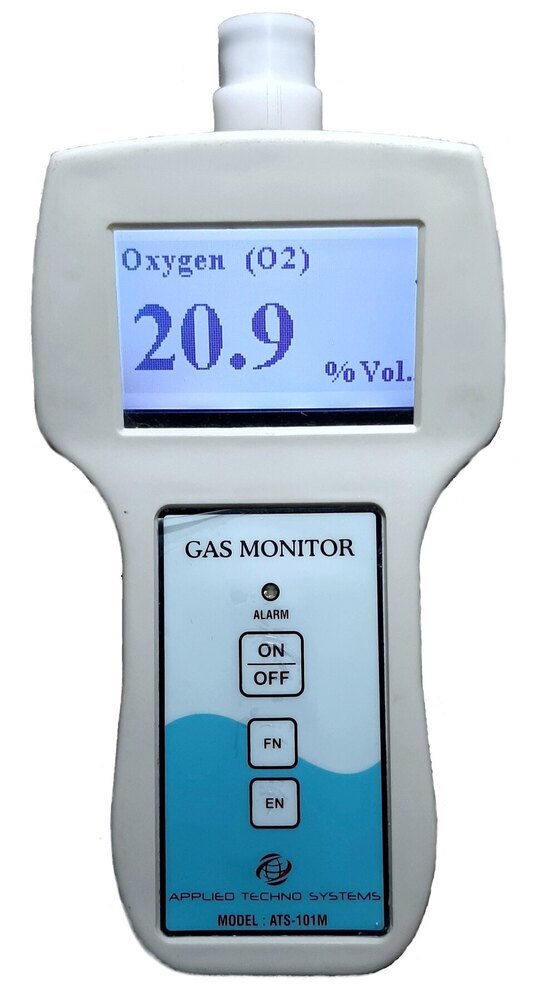

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Combustion Gas Analyzer

Price 158000 INR/ Unit

Combustion Gas Analyzer Specification

- Dimension (L*W*H)

- 430 x 260 x 150 Millimeter (mm)

- Usage

- Industrial

- Weight

- 1.5 Kilograms (kg)

- Material

- Aluminium

- Voltage

- 230 Volt (v)

- Humidity

- 85% RH

- Color

- Grey

- Power Supply

- Electric

- Temperature

- -40 to 55 Celsius (oC)

Combustion Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 2 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Combustion Gas Analyzer

A combustion gas analyzer is a device used to measure the concentration of gases produced during the combustion process in boilers, furnaces, and engines. These analyzers monitor emissions of gases such as oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and sulfur dioxide (SO2) to ensure optimal combustion efficiency, safety, and environmental compliance.

Combustion gas analyzers are widely used in industries like power generation, manufacturing, automotive, and HVAC systems. They are critical for reducing fuel consumption, optimizing energy use, and controlling pollution. Most analyzers are equipped with sensors and provide real-time data that allows operators to adjust combustion parameters.

Key Features:

- Multi-gas detection: Monitors various gases such as CO, CO2, O2, NOx, and SO2.

- Portability: Many models are handheld, making them suitable for field use.

- Data logging: Records data for later analysis and reporting.

- Real-time measurement: Provides instant feedback on combustion efficiency.

- User interface: Displays information clearly, often with touchscreens or buttons for ease of use.

Frequently Asked Questions (FAQs)

What gases does a combustion gas analyzer measure?

Most combustion gas analyzers measure oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and sulfur dioxide (SO2). Some models may also detect unburned hydrocarbons or methane.

Why is a combustion gas analyzer important?

It helps optimize combustion efficiency by ensuring the proper air-fuel ratio, thereby improving fuel economy, reducing emissions, and maintaining compliance with environmental regulations. It also helps prevent the release of harmful gases that can lead to safety hazards or regulatory fines.

How does a combustion gas analyzer work?

The analyzer uses sensors to measure the concentration of various gases in the exhaust or flue gas. For example, electrochemical sensors detect oxygen levels, while infrared or chemical sensors measure CO and CO2 concentrations. The readings help operators adjust the combustion process for better efficiency and reduced emissions.

What industries use combustion gas analyzers?

Combustion gas analyzers are used in power plants, oil and gas refineries, automotive industries, HVAC systems, manufacturing plants, and other sectors where fuel combustion occurs.

How often should a combustion gas analyzer be calibrated?

It depends on the frequency of use and the model, but typically, combustion gas analyzers should be calibrated every 6 to 12 months to ensure accurate readings. Some analyzers may require more frequent calibration based on operating conditions.

Can combustion gas analyzers detect gas leaks?

While combustion gas analyzers primarily measure emissions, some models may have features that help detect gas leaks, especially for flammable gases like methane. However, dedicated leak detectors are more effective for this purpose.

What is the difference between a combustion analyzer and a flue gas analyzer?

A combustion analyzer focuses on optimizing the combustion process by measuring the concentration of gases like O2, CO, and CO2 in the combustion chamber. A flue gas analyzer measures the composition of gases in the exhaust flue, typically monitoring emissions from the entire system.

How long does a combustion gas analyzer last?

With proper maintenance and regular calibration, a high-quality combustion gas analyzer can last several years. However, sensor life can vary and may need replacement depending on usage and the operating environment.

Are combustion gas analyzers portable?

Many models are designed for portability, allowing users to take measurements in various locations. These handheld models are often used for HVAC maintenance and field testing.

How can I ensure accurate readings from my combustion gas analyzer?

Regular calibration, proper sensor maintenance, and following the manufacturers guidelines for use and storage can ensure accurate readings. Its also important to check for sensor degradation over time

High-Precision Gas Measurement

Our combustion gas analyzer is engineered for detailed gas analysis in industrial environments. Its advanced sensors ensure accurate readings, even in challenging temperature and humidity conditions, making it ideal for process optimization and compliance monitoring.

Designed for Durability and Convenience

The units aluminium construction ensures strength while remaining lightweight, aiding easy handling and portability. Its compact dimensions make integration simple within existing setups, and electric power supply ensures consistent performance during extended operations.

FAQs of Combustion Gas Analyzer:

Q: How do I use the combustion gas analyzer for industrial applications?

A: To use the analyzer, connect it to a 230 Volt power source, install it near the combustion system, and follow the manufacturers instructions to conduct gas measurements. Its compact size allows flexible positioning in industrial settings.Q: What is the process for measuring exhaust gases with this analyzer?

A: The analyzer samples gases from combustion sources such as boilers or furnaces, then uses its integrated sensors to quantify various gas concentrations, providing real-time data essential for safety and efficiency improvements.Q: When should I calibrate the combustion gas analyzer?

A: Calibration should be performed periodically, as recommended by the manufacturer, or before critical measurements, to ensure ongoing accuracy, especially in demanding environments with fluctuating humidity and temperature.Q: Where can I purchase or service the combustion gas analyzer in India?

A: You can obtain the analyzer or arrange servicing through reputable exporters, importers, manufacturers, service providers, and suppliers located across India who specialize in industrial instrumentation.Q: What are the benefits of using this combustion gas analyzer?

A: This analyzer enhances safety and efficiency by providing precise measurements, aiding regulatory compliance, and identifying optimization opportunities in combustion processes, thereby reducing emissions and costs.Q: How does the device perform in high humidity and extreme temperatures?

A: The analyzer is built to operate reliably in environments with up to 85% relative humidity and temperatures ranging from -40 to 55C, ensuring consistent results in varied industrial climates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Portable NO2 Analyzer

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Onsite, Field Use, Lab Use

Power Supply : Rechargeable Battery / 220V AC Adapter

Automation Grade : SemiAutomatic

Online Nox Analyzer

Price 365500 INR / Pack

Minimum Order Quantity : 1 Pack

Usage : Industrial

Power Supply : Electric

Material : Aluminum

Headspace Gas Analyser

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Material : MS

Automation Grade : Semiautomatic

Flue Gas Analyser

Price 185000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Supply : Electric

Material : MS

Automation Grade : Semiautomatic

Send Inquiry

Send Inquiry