- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

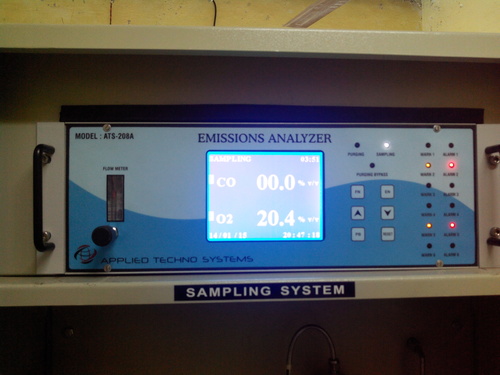

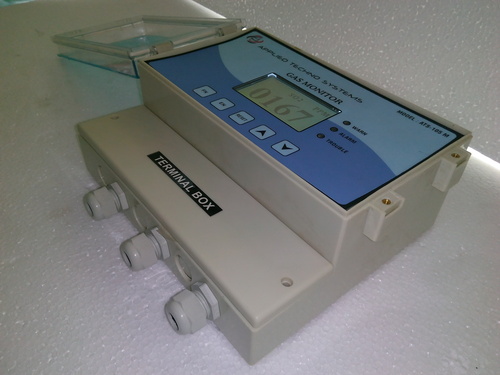

Fixed Gas Monitoring system

Price 50000 INR/ Unit

Fixed Gas Monitoring system Specification

- Usage

- Industrial

- Color

- Black Grey

- Material

- Mild Steel

- Product Type

- Fixed Gas Monitoring system

- Warranty

- 1 Year

- Frequency

- 50 Hertz (HZ)

- Remote Control

- No

- Power Supply

- Electric

Fixed Gas Monitoring system Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Units Per Week

- Delivery Time

- 3 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Fixed Gas Monitoring system

A Fixed Gas Monitoring System is a permanently installed gas detection system used in industrial and commercial environments to continuously monitor the presence of hazardous gases. These systems are designed to protect facilities, equipment, and personnel by providing real-time detection and alerts when dangerous gas concentrations (e.g., toxic, flammable, or asphyxiant gases) are detected.

Fixed gas monitors are typically placed at strategic locations where gas leaks or accumulation are likely, such as in processing plants, refineries, power generation facilities, and storage areas. They provide 24/7 monitoring and are integrated with control systems to trigger alarms, ventilation, or even shut down processes automatically in case of dangerous gas levels.

Key Features:

- Continuous Monitoring: Fixed systems provide real-time, around-the-clock gas detection.

- Multi-point Detection: Can monitor multiple gas types and points across large areas.

- Integration with Safety Systems: Often integrated with control panels and automated safety systems to trigger responses like alarms or ventilation activation.

- Sensor Technology: Various sensors, such as infrared, electrochemical, catalytic bead, or photoionization detectors, depending on the gas type.

- Data Logging: Continuous recording of gas levels for compliance, analysis, and maintenance purposes.

- Customizable Alerts: Visual, audible alarms, and remote notifications when gas concentrations reach unsafe levels.

Typical Applications:

- Oil & Gas Refineries

- Chemical Plants

- Power Plants

- Manufacturing Industries

- Wastewater Treatment Plants

- Pharmaceutical and Research Labs

FAQs about Fixed Gas Monitoring Systems:

What is the purpose of a fixed gas monitoring system?

A fixed gas monitoring system is installed to detect hazardous gases in real-time, ensuring the safety of personnel and the facility by preventing accidents due to gas leaks or buildup.

What types of gases can a fixed gas monitoring system detect?

These systems can detect a wide range of gases, including toxic gases like hydrogen sulfide (H2S) and carbon monoxide (CO), combustible gases like methane (CH4), and oxygen (O2) deficiency or enrichment.

How does a fixed gas monitor differ from a portable gas detector?

A fixed gas monitor is permanently installed and provides continuous monitoring in a fixed location, while a portable gas detector is a handheld device used for temporary or personal gas monitoring.

How are fixed gas monitors powered?

Most fixed gas monitors are powered by the facilitys electrical systems, though backup batteries or other power sources are available to ensure uninterrupted operation during power outages.

Can fixed gas monitoring systems be integrated with alarm systems?

Yes, they are commonly integrated with alarm systems, both visual and audible, and may also be connected to emergency shutdown or ventilation systems.

How often should fixed gas monitors be calibrated?

Calibration frequency depends on the sensor type and manufacturer recommendations, but calibration typically occurs every 6 to 12 months to ensure accuracy.

What is the lifespan of the sensors in fixed gas monitoring systems?

Sensor lifespan varies by type, but most electrochemical sensors last 2-3 years, while infrared sensors may last longer. Regular maintenance is required to ensure optimal performance.

Are fixed gas monitors suitable for hazardous environments?

Yes, many fixed gas monitors are specifically designed for hazardous environments and come with explosion-proof housings to ensure safety in areas with combustible gases.

What industries benefit from fixed gas monitoring systems?

Industries such as oil and gas, chemical processing, power generation, manufacturing, and laboratories rely on these systems to ensure safety by detecting dangerous gas levels.

How are fixed gas monitoring systems maintained?

Regular sensor calibration, testing, and maintenance checks are necessary to ensure system accuracy and performance. Many systems come with self-diagnostic features to monitor sensor health and alert users to any issues

Reliable Gas Detection for Industry

Engineered specifically for industrial settings, this fixed gas monitoring system provides continuous detection of hazardous gases. With its sturdy mild steel body and operational frequency of 50 Hertz, it withstands demanding conditions while maintaining accuracy. The black-grey finish not only adds to its aesthetic appeal but also contributes to its resiliency in various environments.

Comprehensive Support and Service Across India

As an exporter, importer, manufacturer, service provider, and supplier based in India, the company ensures end-to-end assistance. From supply and installation to after-sales service and warranty support, customers benefit from dependable solutions aimed at maximizing productivity and safety in their facilities.

FAQs of Fixed Gas Monitoring system:

Q: How does the Fixed Gas Monitoring System operate in industrial environments?

A: The system operates through continuous real-time detection of hazardous gases using sensors connected to an electric power supply at 50 Hertz. Its sturdy mild steel construction ensures reliable performance even in harsh industrial conditions.Q: What is the process for installing and commissioning this gas monitoring system?

A: The installation involves mounting the device in designated industrial zones, connecting to a compatible electric source, and following calibration procedures. Manufacturer-trained technicians can provide support for commissioning and initial configuration.Q: When should this fixed gas monitoring system be used?

A: It should be used in industrial areas where there is a potential risk of hazardous gas leaks, such as manufacturing plants, chemical processing facilities, or storage zones, to ensure continuous monitoring and enhanced safety.Q: Where can the system be deployed within a facility?

A: The system can be installed in areas prone to gas exposure, such as machinery rooms, production floors, or near gas storage units. Proper placement is essential for effective monitoring and timely hazard alerts.Q: What are the key benefits of using this system for gas monitoring?

A: The system greatly improves workplace safety by detecting gas leaks early, allowing timely intervention. It also helps organizations comply with regulatory standards and protects both personnel and equipment from harmful exposure.Q: Is there any remote control capability included with this monitoring system?

A: No, this particular model does not feature remote control. It is designed for manual operation to ensure secure and reliable monitoring directly from the installed location.Q: What kind of warranty and after-sales service is offered for this product?

A: This gas monitoring system comes with a 1-year warranty. The supplier provides comprehensive after-sales support, including maintenance services and prompt response to technical inquiries throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Monitoring Systems Category

Ambient Monitoring Systems

Price 329500 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : 230 VAC

Usage : Industrial

Material : Mild Steel

Color : White

Multi Channel Gas Monitors

Price 18500 INR / Piece

Minimum Order Quantity : 1 Set

Power Supply : 230 V

Usage : Industrial

Material : ABS

Combustible Gas Monitor

Price 22520 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : Electric

Usage : Industrial

Material : Mild Steel

Color : White

Multi Gas Monitor

Price 12500 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : Electric

Usage : Industrial

Material : Mild Steel

Color : White

Send Inquiry

Send Inquiry