- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

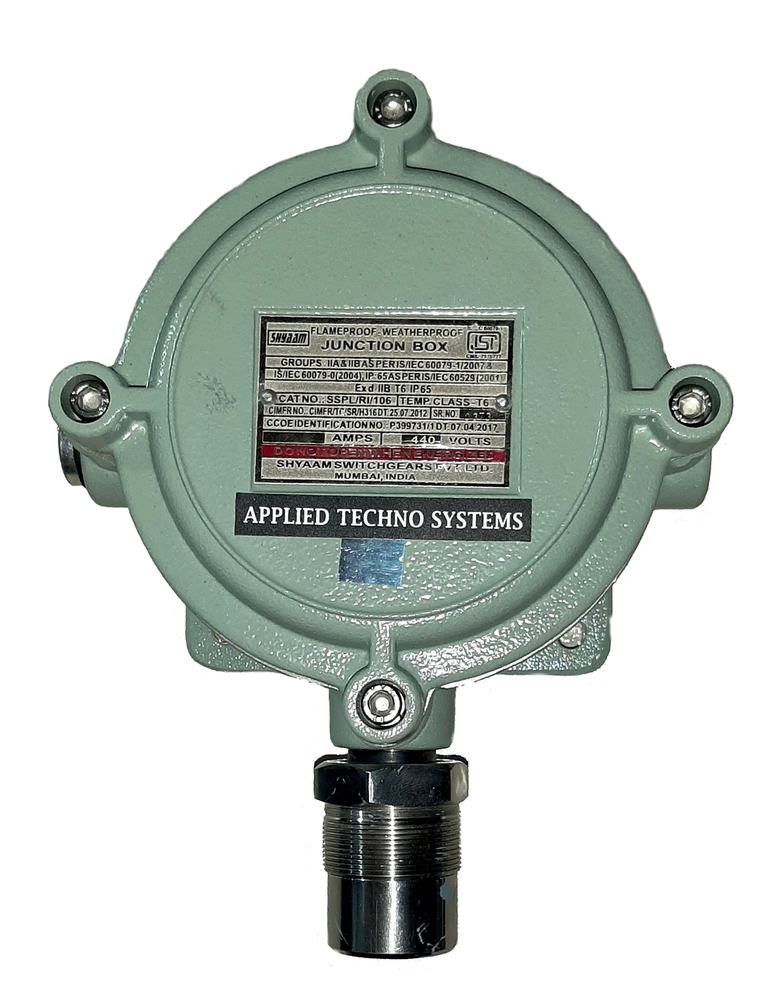

- Gas Sensor Transmitter

Gas sensor transmitters

Price 40000 INR/ Unit

Gas sensor transmitters Specification

- Material

- Mild Steel

- Output

- 4-20mA

- Usage

- Industrial

- Accuracy

- +/-2 %

- Voltage

- 230 Volt (v)

- Warranty

- 1 Year

Gas sensor transmitters Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Gas sensor transmitters

A gas sensor transmitter is an electronic device that detects and measures the concentration of specific gases in the environment. It converts the detected gas concentration into a standardized signal (usually 4-20 mA or digital) that can be transmitted to control systems or monitoring equipment. These devices are essential for ensuring safety in industrial, commercial, and residential settings by providing real-time data on gas levels.

Key Components:

Gas Sensor: The core component that detects gas concentrations. Types include electrochemical, infrared, catalytic, and photoionization sensors.- Microcontroller: Processes the signals from the sensor, interprets the data, and controls the transmitters functions.

- Display/Indicator: Some models feature a built-in display for real-time readings, while others use LED indicators for alarms.

- Communication Interface: Outputs the data in various formats, including analog (4-20 mA) and digital (Modbus, RS-485).

- Alarm System: Alerts users when gas levels exceed safe thresholds, typically through audible alarms, visual signals, or notifications to connected systems.

- Power Supply: Can be powered by batteries, AC power, or solar energy, depending on the application.

Applications:

- Industrial Facilities: Used to monitor hazardous gases in manufacturing, chemical processing, and oil and gas industries.

- Environmental Monitoring: Assess air quality in urban areas and compliance with environmental regulations.

- Mining Operations: Detect dangerous gases in underground mining environments to protect workers.

- HVAC Systems: Monitor indoor air quality and optimize ventilation in buildings.

FAQs

What gases can gas sensor transmitters detect?

Gas sensor transmitters can detect various gases, including carbon monoxide (CO), carbon dioxide (CO2), methane (CH4), hydrogen sulfide (H2S), ammonia (NH3), and volatile organic compounds (VOCs).

How do gas sensor transmitters work?

The transmitter detects gas concentrations using specific sensors, converts the detected levels into an electrical signal, and transmits this signal for monitoring or control purposes.

What is the typical output signal of a gas sensor transmitter?

Most gas sensor transmitters output signals in the form of a 4-20 mA analog signal or digital communication protocols such as Modbus or RS-485.

How often should gas sensor transmitters be calibrated?

Calibration frequency depends on the application and environmental conditions but is generally recommended every 6 to 12 months to ensure accuracy.

Can gas sensor transmitters be used in outdoor environments?

Yes, many gas sensor transmitters are designed to be rugged and weatherproof, making them suitable for outdoor use. However, specific models may have limitations, so always check the manufacturers specifications.

What should I do if the gas sensor transmitter alarms?

Immediately investigate the cause of the alarm by checking the gas levels in the area. Follow your facilitys safety protocols, which may include evacuating the area, ventilating the space, or contacting emergency services.

Are gas sensor transmitters suitable for residential use?

Yes, there are gas sensor transmitters designed for residential applications, such as detecting carbon monoxide or natural gas leaks.

Can gas sensor transmitters be integrated with existing control systems?

Most modern gas sensor transmitters can be easily integrated into existing control and monitoring systems, thanks to standard output signals and communication protocols.

What maintenance is required for gas sensor transmitters?

Routine maintenance includes cleaning the sensors, checking power supplies, and performing periodic calibrations to ensure accurate readings and reliable performance.

What factors can affect the accuracy of gas sensor transmitters?

Environmental factors such as temperature, humidity, and the presence of interfering gases can affect sensor accuracy. Regular calibration and maintenance are essential to mitigate these effects

Reliable Industrial Monitoring

Engineered for precision, our gas sensor transmitters facilitate continuous monitoring of gases in industrial settings. Mild steel construction ensures longevity even in challenging conditions, while the high accuracy of 2% delivers confidence in detecting and controlling hazardous gases. The 4-20mA output integration makes it simple for industries to incorporate sensors into existing safety and control systems.

Comprehensive Support Across India

Serving as exporters, importers, manufacturers, service providers, and suppliers, we cater to the broad spectrum of industrial safety needs throughout India. Our team provides expert guidance for installation and ongoing maintenance, ensuring optimal sensor performance. Each device comes with a 1-year warranty, reflecting our commitment to quality and customer satisfaction.

FAQs of Gas sensor transmitters:

Q: How are gas sensor transmitters installed in industrial environments?

A: Gas sensor transmitters are typically mounted in locations where gas leaks or accumulation are most likely. They require a stable 230 Volt (v) supply and can be integrated into existing monitoring systems using the standard 4-20mA output. Professional installation is recommended to ensure accuracy and safety.Q: What gases can these transmitters detect in industrial applications?

A: The transmitters are designed for versatile use and can detect a wide range of hazardous and operational gases, depending on the sensor type selected. For specific gas detection requirements, please consult our technical team during the selection process.Q: When should the gas sensor transmitters be calibrated or maintained?

A: Regular calibration is essential for maintaining the 2% accuracy of the transmitters. It is recommended to perform calibration and maintenance checks at least once a year, coinciding with the warranty period, or more frequently if used in high-risk environments.Q: Where are your gas sensor transmitters available in India?

A: We supply our gas sensor transmitters across India through our extensive network serving exporters, importers, manufacturers, service providers, and suppliers. Detailed distribution and installation support is available nationwide.Q: What is the process for claiming warranty or technical support?

A: If a transmitter experiences issues within the 1-year warranty period, customers can contact our support team with purchase details. Our service department coordinates inspection, repair, or replacement processes swiftly to minimize downtime.Q: How is the output from the transmitter utilized by industrial systems?

A: The 4-20mA output allows seamless integration with PLCs, SCADA systems, and other industrial automation equipment, enabling real-time monitoring and automatic gas leak response protocols to enhance workplace safety.Q: What are the benefits of using mild steel in the transmitters construction?

A: Mild steel offers robust protection against environmental hazards, extending the lifespan and reliability of the transmitter in harsh industrial settings. It also provides good corrosion resistance, making it ideal for long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Sensor Transmitter Category

Oxygen Sensor With Transmitter

Price 26500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 24V DC

Material : Stainless Steel Body, Sensitive Ceramic Element

Usage : Industrial Oxygen Level Monitoring

LEL Gas Sensor Transmitter

Price 35000 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 24 Volt (v)

Material : Flameproof

Usage : Gas Detection

Warranty : 1 Year

Ammonia Gas Sensor Transmitter without Display

Price 32500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 110215 Volt (v)

Material : MS

Usage : industrial

Warranty : 1 year

Online Ammonia Gas Sensor Transmitter

Price 80000 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 230 Volt (v)

Material : Mild Steel

Usage : Industrial

Warranty : 1 Year

Send Inquiry

Send Inquiry