- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

High-purity hydrogen Analyzer

Price 165000 INR/ Number

MOQ : 1 Unit

High-purity hydrogen Analyzer Specification

- Temperature

- 0 - 55 Celsius (oC)

- Humidity

- 85%RH

- Material

- Aluminum

- Power Supply

- Electric

- Voltage

- 240 Volt (v)

- Usage

- Industrial

- Dimension (L*W*H)

- 450 x 300 x 200 Millimeter (mm)

- Color

- Grey

About High-purity hydrogen Analyzer

| Model Name/Number | ATS-202 |

| Usage/Application | Industrial |

| Brand | Applied Techno Systems |

| Display Type | 128 X 64 Graphics LCD |

| Weight | 1.5 Kg |

| Material | ABS Plastic |

| Dimensions | 200 X 120 X 185 mm (W x H x D) |

| Accuracy | +/- 2% |

| Power Source | Built in Lithium Rechargeable Battery |

| Country of Origin | Made in India |

Reliable Hydrogen Measurement

This analyzer ensures accurate and consistent detection of high-purity hydrogen, vital for various industrial applications. Its sophisticated technology minimizes errors, supporting optimal process control and product quality, even in high-humidity or fluctuating temperatures up to 55C.

Robust Construction and Design

The use of high-grade aluminum offers both strength and corrosion resistance, ensuring longevity and system reliability. Its compact dimensions (450 x 300 x 200 mm) allow for easy integration into diverse laboratory and plant settings, providing flexibility in installation and operation.

FAQs of High-purity hydrogen Analyzer:

Q: How does the High-purity Hydrogen Analyzer work in industrial environments?

A: The analyzer operates by utilizing advanced electrochemical sensors powered by a 240-volt electric supply, delivering precise hydrogen measurements even in harsh industrial conditions. Its robust aluminum body and sealed design help maintain accuracy at humidity levels up to 85% and temperatures from 0 to 55C.Q: What makes this hydrogen analyzer suitable for exporting and industrial applications?

A: Its high measurement accuracy, compliance with industrial standards, and durable construction make it suitable for various sectors, ensuring reliable results for exporters, importers, manufacturers, and service providers. Its versatility extends usability across production, quality control, and research laboratories.Q: When should routine maintenance be performed on this analyzer?

A: Routine maintenance should be conducted periodically, based on manufacturer guidelines or operational hours, to ensure optimal sensor performance and longevity. Regular calibration and cleaning, especially in environments with fluctuating humidity or dust, are recommended for accurate results.Q: Where is the optimal installation location for this analyzer?

A: Install the analyzer in well-ventilated areas away from direct exposure to corrosive agents or extreme temperatures. Its compact dimensions allow for easy placement on benchtops, within analytical laboratories, or close to production lines in industrial facilities.Q: What is the process of analyzing hydrogen purity using this device?

A: The device samples hydrogen from the process stream, passing it through advanced sensors to determine purity levels. Real-time data is then provided for immediate quality assessment or process adjustment, supporting compliance and safety standards.Q: How is the analyzer powered and what are the electrical requirements?

A: The device operates with a standard 240-volt electric supply, making it compatible with most industrial power setups across India. Reliable electric power is essential for continuous, accurate operation.Q: What are the key benefits of using this hydrogen analyzer in industrial settings?

A: Benefits include precise measurement of hydrogen purity, enhanced product safety, compliance with regulatory requirements, and reduced operational downtime due to robust construction and user-friendly interface. Its adaptability to varying humidity and temperature conditions increases operational reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gas Analysers Category

Exhaust Gas Analyzers

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Mild Steel

Power Supply : Electric

Ammonia Gas Analyser

Price 225000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : MS

Voltage : 110215 Volt (v)

Ammonia Gas Analyzer

Price 386500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Usage : Industrial, Laboratory

Material : Aluminium

Voltage : 230 V Volt (v)

Power Supply : Electric

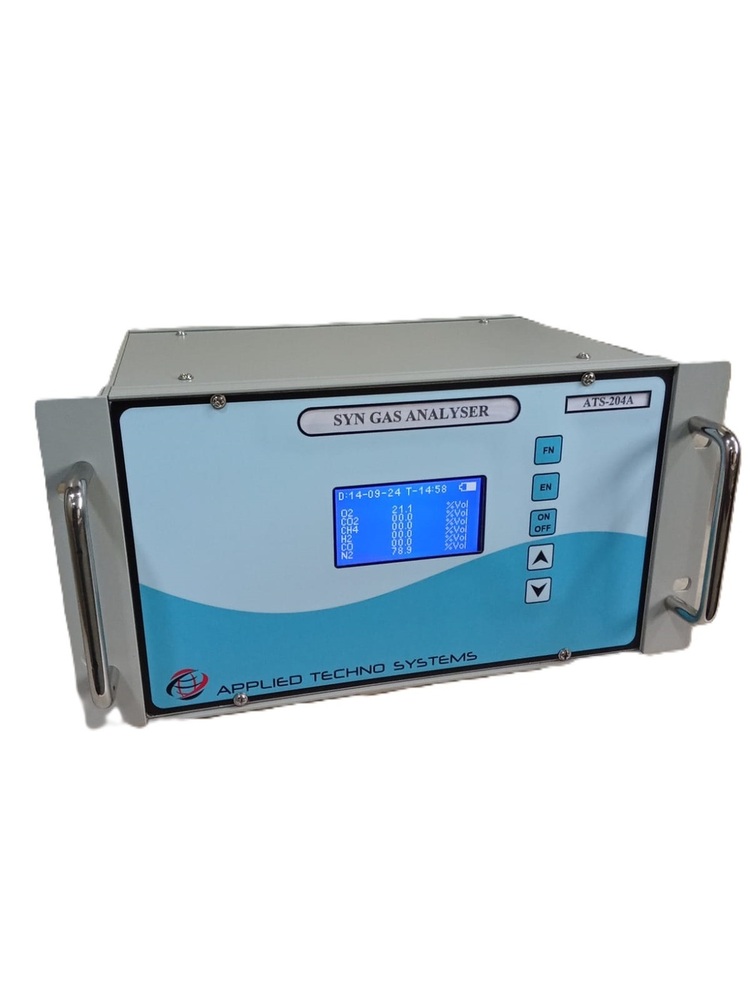

Portable Syngas Analyzer Model ATS 204A

Price 675500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry