- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Industrial Stack Monitoring System

Price 62500 INR/ Set

Industrial Stack Monitoring System Specification

- Dimension (L*W*H)

- 430 (X 150 X 250( Millimeter (mm)

- Features

- High Quality

- Weight

- 2.5 Kilograms (kg)

- Display Type

- Digital

- Temperature

- 15 Celsius (oC)

- Humidity

- < 85%RH

- Power Supply

- Electric

- Accuracy

- +2 %

Industrial Stack Monitoring System Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Mumbai

- Supply Ability

- 20 Sets Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America, North America

- Main Domestic Market

- All India

About Industrial Stack Monitoring System

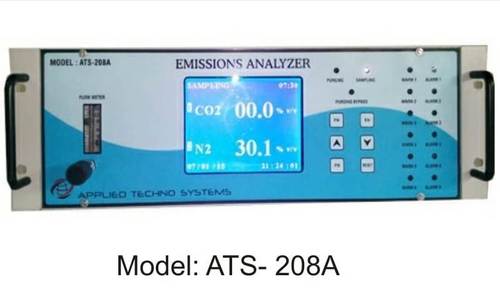

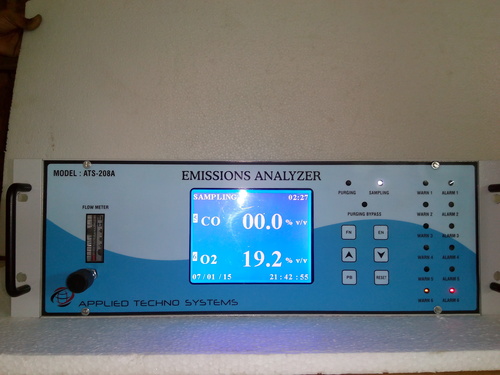

Industrial Stack Monitoring System Model ATS-208A

Model ATS- 208A Online Emission Analyzer continuously monitors the concentration of Flue gases ranging from 100%V/V down to PPM level. Feature includes a duel wavelength sensor, Remote Sampling, Graphics LCD Display, adjustable level relay output for alarm and 4-20mA output for control purpose and minimal maintenance.

Special gas sample Conditioning systems are used to clean and dry the gas sample for accurate and High performance operation. An Internal Pump draw gas sample into the sensor through a dust particle filter from an intake which can be located at distance up to 40 meter form the monitor.

Online Data transmission to CPCB & SPCB through GPRS/GSM technology

The Sensor and Electronic component are housed in tough aluminium housing

Specifications:-

- Principle: Electrochemical, TCD (Thermal Conductivity) , NDIR (Non Dispersive Infrared ), Zirconium and Paramagnetic

- Range: %V/V, % LEL, PPM, Mg/M3

- Resolution: 0.1 Unit or 1 Unit (Application based)

- Sampling Method: Auto Suction

- Display: 320 X 264 Graphic LCD

- Alarm; Relay Contact NO+NC

- Anolog Out Put: 4-20mA

- Digital Out Put : RS 232, RS 485 and Modbus Comminication Protocol

- Power Source:230VAC

- Accuracy: +/2%

- Response Time: <5 Second

- Sensor Life: 2-3 Years

- Environmental:

- Temperature:-15degree Celsius Humidity :< 85%RH Atmosphere Pressure: 86- 106Kpa

- Dimension in mm: 430 (W) X 150(H) X 250(D)

- Weight: 2.5 KG

- Warranty: One Year

Reliable Emission Monitoring

This stack monitoring system is engineered to deliver precise emission measurements across industrial stacks, enabling companies to adhere to environmental regulations. The devices accuracy of 2% ensures confident reporting and aids in detecting deviations swiftly. Its digital interface simplifies data interpretation while streamlining operational workflows.

Advanced Features and Durability

Constructed with high-quality materials, the system is built for durability and long-term use in demanding industrial environments. The digital display provides clear, immediate readings. Operating conditions require a temperature of 15C and relative humidity below 85%, making it suitable for controlled industrial spaces.

Comprehensive Support from India

As a multifaceted supplier based in India, the company offers export, import, manufacturing, and service support for this monitoring system. Clients benefit from expert technical assistance and aftersales service, ensuring continuous and efficient operation.

FAQs of Industrial Stack Monitoring System:

Q: How does the Industrial Stack Monitoring System operate in industrial settings?

A: The system functions by continuously measuring and displaying emission levels from industrial stacks using its digital interface. It has an electric power supply and operates best at 15C with humidity less than 85%RH, ensuring accurate, real-time monitoring and prompt detection of emissions outside compliance limits.Q: What are the main features of this stack monitoring system?

A: Key features include a high-quality build, accurate measurements within 2%, a digital display for easy readings, a compact design (430 x 150 x 250 mm), and light weight at 2.5 kg. These attributes enhance durability, ease of installation, and usability in industrial environments.Q: When is the Industrial Stack Monitoring System recommended for use?

A: It is ideal for use in industrial facilities needing reliable emission monitoring to comply with environmental standards. The system is suited for operations where consistent temperature (15C) and controlled humidity (<85%RH) can be maintained.Q: Where can this stack monitoring system be installed?

A: Due to its compact dimensions and robust design, the system can be installed directly on or near industrial stacks within manufacturing plants, refineries, or any location requiring emissions tracking within the specified environmental conditions.Q: What is the typical process for setting up the system?

A: Installation involves mounting the unit at the monitoring site, connecting the electric power supply, and calibrating it as per manufacturer guidelines. The digital display guides users through setting adjustments and provides real-time emission data once operational.Q: How can companies in India obtain support for this monitoring system?

A: As a supplier, exporter, importer, manufacturer, and service provider in India, comprehensive product support is offered, including installation assistance, technical support, maintenance, and aftersales service to ensure optimal performance.Q: What are the benefits of using this stack monitoring system?

A: The primary benefits include highly accurate and reliable emissions data, digital ease of use, compact footprint, robust design for industrial use, and full local supportenabling better environmental compliance and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Online SO2 Gas Analyzer

Price 325500.00 INR / Pack

Minimum Order Quantity : 1 Pack

Humidity : < 85%RH

Usage : Emission Monitoring in Industries

Power Supply : 230 V AC

Display Type : Digital

Stack Gas Analyzer

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : < 85%RH

Usage : Monitoring and Detection Systems

Power Supply : 200 to 240V a.c, 5060 Hz

Display Type : Digital

Emissions Monitoring System

Price 345000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity : < 85%RH

Usage : Industrial

Power Supply : Electric

Display Type : Digital

Continuous Emission Monitoring System (CEMS)

Price 950000 INR / Pack

Minimum Order Quantity : 1 Pack

Humidity : < 85%RH

Usage : Industrial

Power Supply : Electric

Display Type : Digital

Send Inquiry

Send Inquiry