- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Online Gas Monitoring system

Price 158500 INR/ Set

Online Gas Monitoring system Specification

- Material

- Aluminium

- Voltage

- 230 Volt (v)

- Usage

- Industrial

- Humidity

- 85%RH

- Color

- Grey

- Temperature

- 15 Celsius (oC)

- Weight

- 2.5 Kilograms (kg)

- Dimension (L*W*H)

- 430 x 260 x 150 Millimeter (mm)

Online Gas Monitoring system Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 50 Sets Per Week

- Delivery Time

- 1-2 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Online Gas Monitoring system

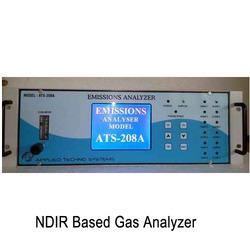

Online Gas Monitoring System Model ATS- 208A

- Model ATS- 208A is Online Gas Monitoring systems continuously monitors the concentration of gases ranging from 100%V/V down to PPM level. Feature includes a duel wavelength sensor, Remote Sampling, Graphics LCD Display, adjustable level relay output for alarm and 4-20mA output for control purpose and minimal maintenance.

- Special gas sample Conditioning systems are used to clean and dry the gas sample for accurate and High performance operation. An Internal Pump draw gas sample into the sensor through a dust particle filter from an intake which can be located at distance up to 40 meter form the monitor.

- The Sensor and Electronic component are housed in tough aluminium housing

Applications

- Metal heat Treatment

- Boiler Systems

- Cement & Lime Manufacturer

- Combustion Process

- Hydrogen Cooled Alternators & Turbine

- Gasification & Syngas

- Pulp & Paper

- Metal Heat Treatment Plant

- Laboratories & Institutions

- Flame Treatment Process & Chemical Industries

- Petrochemical & Pharmaceutical Industries

Industrial-Grade Durability

Encased in robust aluminium, the Online Gas Monitoring System withstands the harsh conditions often found in industrial settings. Its compact design and 2.5 kg weight make it easy to install without compromising on strength, while the grey finish ensures it blends seamlessly with standard facility environments.

Precision Monitoring

Engineered for high humidity levels (up to 85% RH) and temperatures near 15C, this system provides accurate, continuous gas readings. Its advanced sensors guarantee safety and prompt alerts, supporting smooth operations while meeting industry regulations.

Versatile Applications Across Industries

Ideal for exporters, manufacturers, and service providers in India, this monitoring solution is essential for sectors handling gases. Its real-time data capabilities and robust build make it well-suited for high-demand industrial processes, safeguarding both personnel and equipment.

FAQs of Online Gas Monitoring system:

Q: How does the Online Gas Monitoring System operate in high humidity environments?

A: The system is specifically designed to function efficiently at humidity levels up to 85% RH, maintaining sensor accuracy and reliability even in moisture-rich atmospheres common in industrial facilities.Q: What gases can be detected by this monitoring system?

A: The Online Gas Monitoring System is engineered to detect a range of industrial gases commonly encountered in manufacturing and processing plants. For detailed gas compatibility, consult the manufacturer or supplier.Q: When should the Online Gas Monitoring System be used in industrial settings?

A: This system should be used whenever continuous and real-time monitoring of gas concentrations is required to ensure workplace safety, regulatory compliance, or process efficiency, especially in environments prone to high humidity.Q: Where can the monitoring system be installed within a facility?

A: Thanks to its compact size and lightweight build, the system can be installed at critical points within industrial plantsincluding processing lines, storage areas, and hazardous zoneswhere gas leaks or accumulation are potential risks.Q: What is the installation process for the gas monitoring system?

A: The unit can be easily mounted using the provided fittings. It requires a 230 Volt power supply and should be positioned in areas most susceptible to gas exposure, as per the facilitys safety plan.Q: How is real-time data from the gas monitor accessed and acted upon?

A: Data from the system is transmitted continuously, enabling supervisors to receive instant alerts in case of hazardous gas levels. This allows for immediate corrective action, reducing safety risks and downtime.Q: What are the main benefits of using this Online Gas Monitoring System in industrial applications?

A: The system enhances workplace safety by allowing early detection of gas hazards, supports compliance with industrial safety standards, and improves operational efficiency by minimizing the risk of accidents or product loss.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Industrial gas analyzer

Price 158000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : AC 230V, 50/60 Hz

Usage : Industrial, Petrochemical, Pharmaceutical, Environmental monitoring

H2 Purity Analyzer

Price 175500 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : Rechargeable Nicad Battery Pack with Charger.

Usage : Monitoring and Analyzing Systems

Color : Grey

Producer Gas Analyzer

Price 478500 INR / Set

Minimum Order Quantity : 1 Set

Power Supply : Electric

Usage : Industrial

Color : Grey

Material : Aluminium

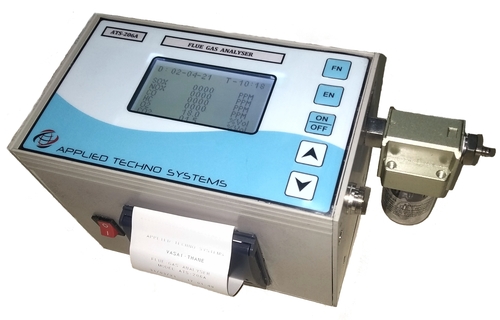

Portable flue gas analyzer with printer

Price 200000 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : Electric

Usage : Industrial

Color : Grey

Material : Mild Steel

Send Inquiry

Send Inquiry