- Dew Point Meters

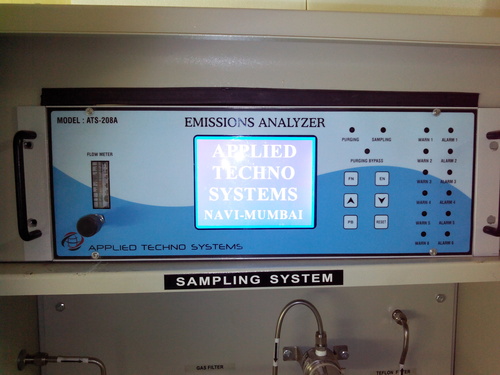

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Producer Gas Analyzer

Price 478500 INR/ Set

Producer Gas Analyzer Specification

- Voltage

- 230 Volt (v)

- Color

- Grey

- Humidity

- 85%RH

- Material

- Aluminium

- Power Supply

- Electric

- Usage

- Industrial

Producer Gas Analyzer Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 50 Sets Per Week

- Delivery Time

- 1-2 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Producer Gas Analyzer

Producer Gas Analyzer

- Basically, gasification is a process where a fuel or feedstock is cooked in low oxygen conditions. The equipment that carries out this whole process is usually called a gasifier.

- Different zones inside the gasifier support drying, pyrolysis, combustion, and reduction reactions. The whole process produces gas that contains primarily carbon monoxide and hydrogen. These gases can be carried away before they combust, and then used elsewhere for energy. The gas is often called synthesis gas or syngas for short. It has also been referred to in the past as producer gas or town gas.

- Applied Model ATS 204A Producer Gas Analyzer has been designed considering the flexibility required in the environments that characterize syn gas and bio-mass applications.

- The analyzer uses high-stability infrared sensors for the simultaneous measurement of CO, CO2 and CH4 . In addition, the analyzer can also be supplied with a non-consumable, long-life thermal conductivity cell for H2 that compensates for the interference effects of CO, CO2 and CH4 . This ensures that H2 will always read 2correctly regardless of the background gas composition. Paramagnetic sensor can be used for O2 analysis as an option.

- All sensors are temperature-compensated for maximum analytical stability.

Applied Techno Systems Advantages

- Ensured after sales & service support

- Spares and accessories availability guaranteed

- Low cost of ownership, maintenance and installation

- Combination of technologies and integration under one roof

Comprehensive Gas Analysis for Industrial Needs

This Producer Gas Analyzer is tailored for heavy-duty industrial applications, providing highly accurate gas assessments. Its robust construction and electric operation ensure consistent performance even in demanding environments with high humidity levels (up to 85% RH).

Durable Aluminium Build with Modern Design

With its aluminium material and contemporary grey finish, the analyzer is built for longevity and efficient operation. It supports continuous usage and resists wear and tear, making it a reliable choice for frequent industrial use.

FAQs of Producer Gas Analyzer:

Q: How does the Producer Gas Analyzer function in high-humidity environments?

A: The Producer Gas Analyzer is engineered to operate effectively in environments with humidity levels up to 85% RH, ensuring reliable measurements and accurate gas analysis without performance degradation.Q: What are the main benefits of using an aluminium-bodied gas analyzer?

A: The aluminium construction provides enhanced durability, corrosion resistance, and a lightweight design, making it suitable for frequent industrial use and easy handling.Q: When should this analyzer be used during the industrial gas production process?

A: It should be employed during or immediately after the gas generation process to monitor quality, check composition, and ensure compliance with safety and environmental standards.Q: Where is this gas analyzer typically installed or deployed?

A: The analyzer is designed for installation in industrial settings across India, particularly in facilities that generate or utilize producer gas as part of their operations.Q: What is the process for operating and maintaining this gas analyzer?

A: The analyzer operates on a simple electric power supply (230 Volt). Regular calibration and routine cleaning are recommended to maintain accuracy and prolong lifespan.Q: How can industrial users benefit from the consistent use of this producer gas analyzer?

A: Consistent use allows users to detect impurities, optimize fuel utilization, and enhance process safety by ensuring that the gas composition meets operational standards, thereby reducing risks and improving efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Analysers Category

Portable Hydrogen Gas Purity Analyzer

Price 34500 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 3.7 V DC Long Life Lithium Rechargeable Battery

Usage : Monitoring and Detection Systems

Humidity : < 85%RH

Temperature : 15 Celsius (oC)

SO2 Gas Analyzer

Price 328500 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : Electric

Usage : Industrial

Humidity : < 85%RH

Temperature : 15 Reaumur (oRe)

Tri Gas Analyser

Price 328400 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : Electric

Usage : Industrial

Humidity : < 85%RH

Temperature : 15 Celsius (oC)

Trace Oxygen Gas Analyzer Model ATS 205A

Price 325000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : Manual

Usage : Industrial

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese