- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

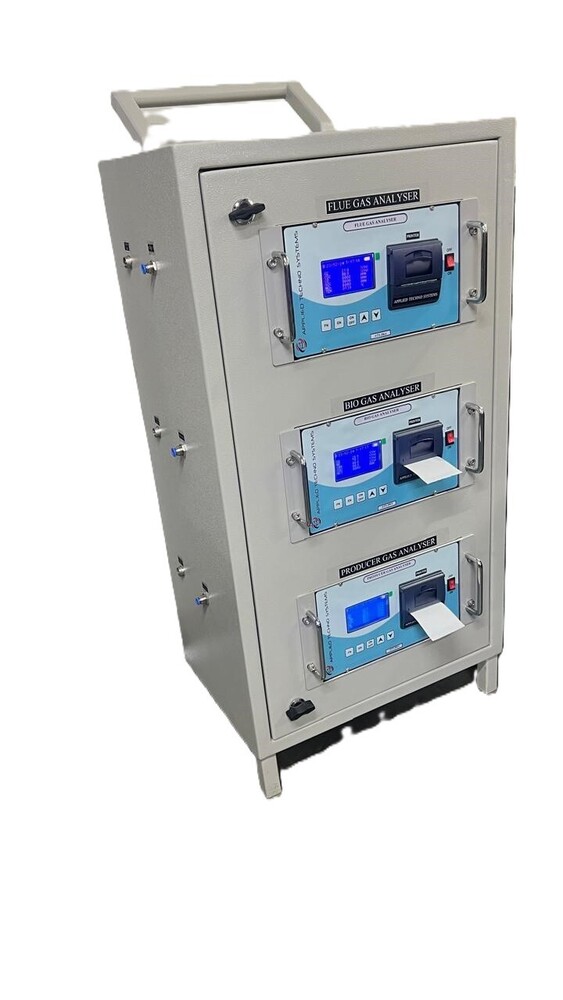

Online Multi Gas Analyser

Price 950000 INR/ Unit

MOQ : 1 Unit

Online Multi Gas Analyser Specification

- Sensor Type

- EC & NDIR

- Resolution

- 0.01 %

- Measurement Range

- 0 - 99.99% V/V

- Usage

- Monitoring & Analysing

- Product Type

- Analyser

- Display Type

- Analog And Digital

- Range

- 0 - 100% V/V

Online Multi Gas Analyser Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Western Union

- Packaging Details

- As Per Customer requirement

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About Online Multi Gas Analyser

An An Online Gas Analyzer is a continuous gas monitoring system that measures the concentration of specific gases in industrial processes, emissions, and environmental monitoring.

The analyzer continuously extracts gas samples and measures their concentration using various technologies like NDIR (Non-Dispersive Infrared), Electrochemical, Zirconia, and Paramagnetic sensors. The data is displayed in real-time and can be integrated with control systems.

Power Plants Emission monitoring

- Cement & Steel Plants Combustion efficiency

- Food & Beverage Industry Controlled atmosphere monitoring

- Pharmaceuticals Gas purity analysis

- Waste & Water Treatment Biogas monitoring

Oxygen

- Carbon Dioxide (CO)

- Carbon Monoxide (CO)

- Nitrogen Oxides (NOx)

- Sulfur Dioxide (SO)

- Hydrogen Sulfide (HS)

- Methane (CH)

- Ammonia (NH)

- Hydrocarbons (HC)

The accuracy depends on the sensor type and application. High-end analyzers offer precision within -/+ 0.1% to -/+ 2% of the measured gas concentration.

Calibration intervals vary by industry, but annual calibration is typically recommended to maintain measurement accuracy. Some industries may require more frequent calibration.

Yes, modern analyzers support remote monitoring and data integration via Ethernet, Modbus, and cloud-based systems for easy access to real-time data.

Improves process efficiency and combustion control

- Ensures compliance with environmental regulations

- Reduces operational costs by optimizing gas usage

- Enhances workplace safety by detecting harmful gases

- Provides real-time alerts and automated reporting

Versatile Gas Monitoring Capabilities

This analyser is engineered to accurately detect and quantify multiple gases in real-time. Its analog and digital display options make data interpretation straightforward for operators across different sectors, from manufacturing to environmental management.

Advanced Sensor Technology

The inclusion of Electrochemical (EC) and Non-dispersive Infrared (NDIR) sensors ensures comprehensive gas detection and reliable, stable readings. These technologies enable the analyser to function effectively across the entire measurement rangefrom trace levels to full concentration.

Ideal for Diverse Industrial Applications

Suited for continuous monitoring, the analyser supports industries spanning petrochemicals, pharmaceuticals, environmental agencies, and beyond. Its flexible sensor technology and robust measurement capabilities address stringent monitoring requirements in high-demand environments.

FAQs of Online Multi Gas Analyser:

Q: How does the Online Multi Gas Analyser operate for gas monitoring and analysis?

A: The analyser utilises advanced EC and NDIR sensors to detect and quantify gas concentrations in real time. It captures sample gases, processes the data, and displays the results in both analog and digital formats for easy interpretation.Q: What benefits does the dual display (analog and digital) offer to users?

A: The dual display ensures users can quickly gather information at a glance (analog) while also allowing for precise digital readings. This enhances usability in environments where both rapid assessment and detailed data are required.Q: When is it recommended to use this multi gas analyser in industrial settings?

A: It is best used when continuous, precise monitoring of multiple gas concentrations is essentialsuch as during manufacturing processes, environmental assessments, or safety compliance in industrial facilities.Q: Where can the Online Multi Gas Analyser be installed for optimal performance?

A: The analyser can be installed in-process lines, environmental monitoring stations, laboratories, or any site where gas concentration data is needed. Placement should ensure exposure to representative gas samples for accurate readings.Q: What is the process for maintaining and calibrating the gas analyser?

A: Regular maintenance involves checking the sensor condition, cleaning the sampling lines, and calibrating with certified reference gases as per the manufacturers guidelines to maintain accuracy and reliability.Q: How does the high measurement resolution (0.01%) enhance gas analysis accuracy?

A: A high measurement resolution allows for the detection of even slight changes in gas concentrations, which is crucial for applications requiring stringent process control or environmental regulatory compliance.Q: What are the core advantages for exporters and suppliers operating in India?

A: Exporters and suppliers benefit from offering a reliable, precise instrument that meets international standards, bolstering their reputation in both domestic and global markets with a versatile, technologically advanced product.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Effluent Monitoring Systems Category

Water Quality Monitoring System

Price 855000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 220V AC, 50Hz

Display Type : Other, Digital LCD

Material : Industrial Grade Plastic & Metal

High-Accuracy Gas Measurement Systems

Price 78500 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 3.7 V DC Long Life Lithium Rechargeable Battery

Display Type : Other

Usage : Monitoring & Analysing

Continuous Stack Emission Monitor Systems

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 200 to 240V a.c, 5060 Hz

Display Type : Digital Only

Usage : Monitoring

Material : Metal

Online Flue Gas Analyzer

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 230 VAC 50 Hz

Usage : Monitoring & Analysing

Send Inquiry

Send Inquiry