- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

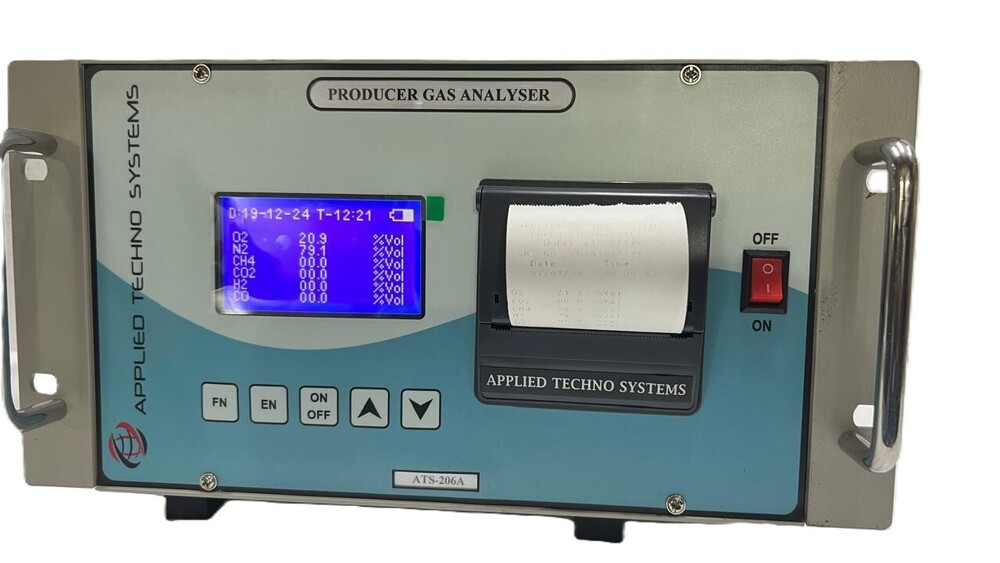

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

ONLINE OXYGEN GAS PURITY ANALYZER

Price 98000.0 INR/ Unit

MOQ : 1 Unit

ONLINE OXYGEN GAS PURITY ANALYZER Specification

- Resolution

- 0.01, 0.1 or 1 PPB, 1 PPM, %V/V, % LEL as applicable

- Display Type

- 320x264 Graphics High Quality LCD

- Product Type

- Analyzer

- Usage

- Monitoring and Analyzing Systems

- Temperature

- 0-250 Deg C Celsius (oC)

- Application

- Analyzer

ONLINE OXYGEN GAS PURITY ANALYZER Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Western Union

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 4 Week

- Packaging Details

- As Per Customer Requirement

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- Certifications

- An ISO 9001:2015 Company

About ONLINE OXYGEN GAS PURITY ANALYZER

| Model Name/Number | ATS 209A |

| Brand | ATS |

| Usage/Application | Oxygen Gas Purity for various industries |

| Product Type | Online |

| Power Supply | 230V AC |

| Features | Complete Automatics Operation |

| Analysis Time | 1-2 sec |

| Color | Light Silver |

| Automation Grade | Automatic |

| Country of Origin | Made in India |

Advanced Gas Purity Analysis

With high-resolution detection capabilities, the analyzer is engineered for industries requiring precise oxygen content measurements. The wide temperature range and flexible resolution settings make it suitable for both routine and demanding applications.

User-Friendly Digital Interface

The large, crisp 320x264 graphics LCD display allows operators to easily interpret data and access system functions quickly. Its intuitive design supports seamless integration into monitoring and analysis workflows, ensuring efficiency and reliability.

FAQs of ONLINE OXYGEN GAS PURITY ANALYZER:

Q: How does the Online Oxygen Gas Purity Analyzer operate across varying temperatures?

A: This analyzer is built to function efficiently within a temperature range of 0 to 250C, enabling reliable performance in diverse and challenging industrial settings.Q: What types of oxygen measurements can this analyzer provide?

A: It offers flexible measurement resolutions, such as 0.01, 0.1, or 1 PPB, 1 PPM, %V/V, and %LEL, allowing you to select the most relevant scale for your specific monitoring or analytical needs.Q: When is it suitable to use this analyzer in industrial processes?

A: It is ideal for continuous or periodic monitoring, especially when precision and safety are crucial, such as during process control, quality assurance, and environmental compliance.Q: Where can this analyzer be deployed in India?

A: The analyzer is supplied to clients across India, including exporters, importers, manufacturers, service providers, and suppliers, offering versatile installation in facilities that require rigorous oxygen monitoring.Q: What is the process for installing and integrating this analyzer with existing systems?

A: Installation is straightforward, and the analyzer can be integrated into existing monitoring and analyzing systems, with technical support available to ensure optimal setup and performance.Q: How does using this analyzer benefit industrial operations?

A: It enhances safety and compliance by providing continuous, accurate oxygen measurements, which are vital for maintaining process integrity and preventing hazardous conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gas Analysers Category

Online Stack Monitoring Systems

Price 345000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Aluminum

Power Supply : Electric

Online Producer Gas Analyzer

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Portable Biogas Analyzer with Printer Model ATS 201A

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Usage : Industrial

Voltage : 110215 Volt (v)

Online Continuous Stack Emission Monitoring Systems Model ATS 208A

Price 850000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : MS

Usage : Industrial

Voltage : 110215 Volt (v)

Send Inquiry

Send Inquiry