- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

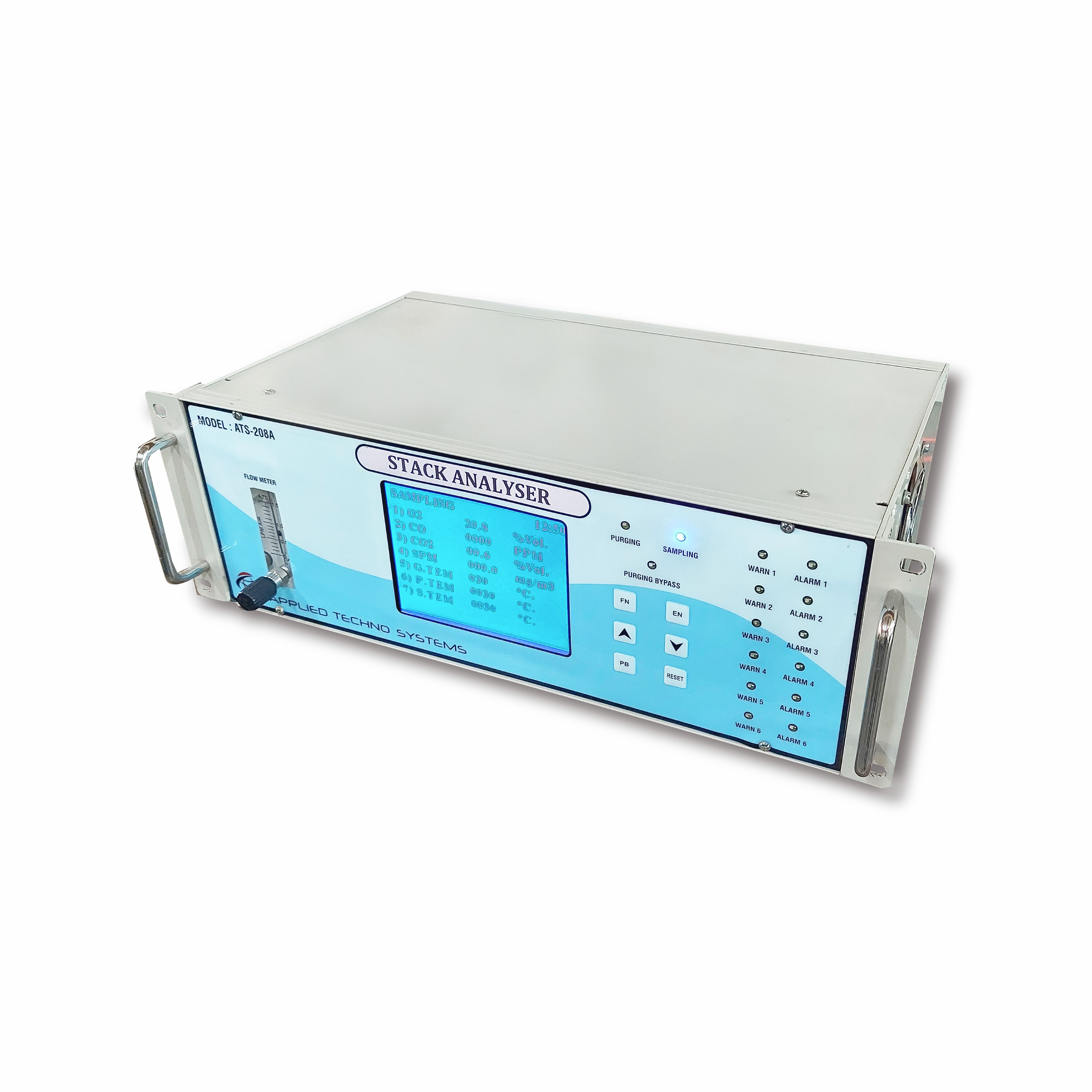

SOx, NOx, and CO monitoring

Price 725000 INR/ Number

SOx, NOx, and CO monitoring Specification

- Humidity

- 96% RH

- Usage

- Industrial, Laboratory

- Power Supply

- Electric

- Voltage

- 230 Volt (v)

- Color

- Grey

- Temperature

- -20 to +50 Celsius (oC)

- Material

- Stainless Steel

About SOx, NOx, and CO monitoring

Measurement Ranges

- SOx (SO): Typical measurement ranges are from 0200 ppm to 05,000 ppm, depending on regulatory requirements and process conditions.

- NOx (NO, NO): Measurement ranges often vary from 0100 ppm to 01,000 ppm, adjustable based on the expected concentration in the exhaust.

- CO: CO is often measured in percentage values, typically 020%, although some applications may require lower or higher ranges (e.g., 050%).

Detection Methods

- SOx: Commonly measured using UV fluorescence, non-dispersive infrared (NDIR), or electrochemical sensors.

- NOx: NOx levels are measured using chemiluminescence, NDIR, or electrochemical detection.

- CO: Primarily monitored using NDIR sensors or infrared gas analyzers.

Response Time

- SOx and NOx: Generally, response times range from 30 seconds to 2 minutes for real-time monitoring.

- CO: Typically has response times around 15 to 30 seconds.

Accuracy and Precision

- SOx: Typically 1% of full scale.

- NOx: Around 2% of full scale.

- CO: 1% of the measurement range.

Resolution

- SOx: Typically around 1 ppm.

- NOx: 0.11 ppm, depending on sensor sensitivity.

- CO: Typically 0.01% for higher precision.

Operating Temperature

- Generally from -20C to +50C for standard stack monitoring systems, but some applications may require operation in higher temperature ranges (up to 300C with cooling or sample conditioning).

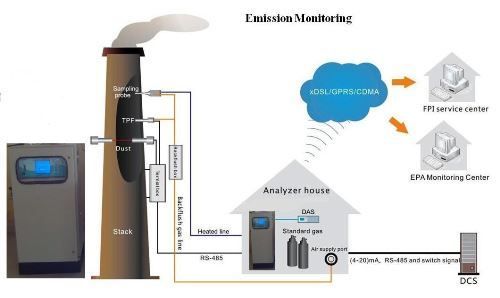

Sample Conditioning System

- Includes filters, condensers, and pumps to prepare samples at high temperatures and humidity, especially in combustion environments.

Data Output and Communication

- Output Signals: 420 mA, RS-485, Modbus, Ethernet for integration with SCADA or other data acquisition systems.

- Data Logging: Systems should have onboard memory and support for data logging, as well as remote data access options.

Compliance Standards

- Should meet standards such as U.S. EPA 40 CFR Part 60, European EN 14181, and local environmental regulations for emissions.

Calibration Requirements

- Automated or manual calibration with span and zero gases (e.g., nitrogen for zeroing, standard reference gases for span calibration). Calibration intervals depend on regulation and analyzer type.

These specifications ensure that SOx, NOx, and CO monitoring systems meet the accuracy, reliability, and regulatory compliance required for effective emissions monitoring in industrial applications

Advanced Gas Monitoring for Maximum Accuracy

Our state-of-the-art monitoring units efficiently detect SOx, NOx, and CO levels, helping industries stay aligned with regulatory standards. The durable stainless steel casing and electric power supply guarantee reliable performance even in rigorous environments. With adaptable usage in both industrial and laboratory scenarios, our devices offer assurance and safety to your operations.

Exceptional Durability and Versatility

Constructed from stainless steel and capable of functioning in high-humidity (96% RH) and wide temperature ranges (-20 to +50C), these monitoring systems suit diverse Indian climates and industrial conditions. Their resilience ensures long-term, uninterrupted service whether you are a supplier, exporter, importer, or manufacturer.

FAQs of SOx, NOx, and CO monitoring:

Q: How does the monitoring device measure SOx, NOx, and CO concentrations?

A: The monitors use advanced sensor technology to detect and quantify SOx, NOx, and CO gases, providing real-time data for accurate environmental assessment in industrial and laboratory settings.Q: What are the main benefits of using these monitoring systems in industrial applications?

A: Benefits include continuous compliance monitoring, improved workplace safety, enhanced process efficiency, and support for responsible environmental management, all made possible by reliable and precise detection capabilities.Q: When should routine maintenance be performed on the gas monitoring devices?

A: Routine maintenance is recommended at regular intervals determined by the manufacturers guidelines, typically every six to twelve months, to ensure peak performance and calibration accuracy under diverse operational conditions.Q: Where can these monitoring systems be installed for optimal effectiveness?

A: These systems are suitable for installation in industrial plants, laboratories, emissions monitoring areas, and any location requiring reliable air quality control within the specified operating temperature and humidity ranges.Q: What process should be followed for installation and initial setup?

A: Installation involves securely mounting the stainless steel device in the desired location, connecting it to a 230 Volt power source, and calibrating sensors according to user instructions to optimize detection sensitivity and accuracy.Q: In what environments can these monitors be effectively used?

A: They function efficiently in environments with up to 96% relative humidity and temperature from -20 to +50C, making them ideal for operations throughout Indias diverse climate conditions.Q: How does continuous usage of the monitoring device benefit regulatory compliance?

A: Continuous use enables prompt detection of harmful gas concentrations, seamless reporting, and proactive adherence to environmental regulations, reducing risks of non-compliance and associated penalties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Online Gas stack Gas Analyzer

Price 850000 INR / Set

Minimum Order Quantity : 1 , , Unit

Humidity : 095%

Temperature : 5 to 55 Celsius (oC)

Power Supply : 230 V

Stack Gas Analyzer

Price 950000 INR / Unit

Minimum Order Quantity : 1 Unit

Humidity : < 85%RH

Temperature : 15 Celsius (oC)

Power Supply : 200 to 240V a.c, 5060 Hz

Display Type : Digital

Emissions Monitoring System

Price 345000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity : < 85%RH

Temperature : 15 Celsius (oC)

Power Supply : Electric

Display Type : Digital

Online Continuous Emissions Monitoring Systems (OCEMS)

Price 725500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Humidity : < 85%RH

Temperature : 5 to +55 Celsius (oC)

Power Supply : 230 V AC 50Hz

Display Type : Digital

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese