- Dew Point Meters

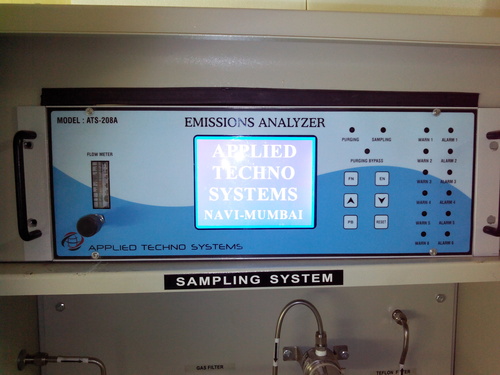

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

TRACED OXYGEN ANALYZER

Price 325000 INR/ Unit

MOQ : 1 Unit

TRACED OXYGEN ANALYZER Specification

- Voltage

- 240 Volt (v)

- Power Supply

- Electric

- Material

- Mild Steel

- Usage

- Industrial

- Color

- Grey

About TRACED OXYGEN ANALYZER

Scope and Purpose

- Define the purpose of the analysis (e.g., purity verification, contamination detection).

- Identify the application area (e.g., industrial gases, medical oxygen).

Applicable Standards

- Reference relevant standards, such as ISO, ASTM, or other industry-specific guidelines.

Technical Specifications

- Analyzed Oxygen Range: Specify the range (e.g., 0-100%).

- Trace Contaminants: List trace impurities to detect (e.g., argon, nitrogen, CO2).

- Sensitivity: Define the minimum detection limits (e.g., ppm or ppb levels).

- Accuracy and Precision: State the required accuracy (e.g., 0.1%) and repeatability.

Equipment and Methods

- Analyzer Type: Specify the equipment (e.g., paramagnetic, zirconia sensors).

- Calibration Requirements: Frequency and type of calibration gases.

- Operating Conditions: Define temperature, pressure, and flow requirements.

- Sample Preparation: Outline steps to ensure accurate sampling.

- Transport and Storage: Describe handling of samples to avoid contamination.

Testing and Reporting

- Procedure: Step-by-step methodology for analysis.

- Data Reporting: Format and units (e.g., % oxygen, ppm for contaminants).

- Acceptance Criteria: Pass/fail thresholds based on application.

Safety Requirements

- Highlight potential risks (e.g., handling compressed gases).

- Include safety measures and personal protective equipment (PPE).

Quality Control

- Describe quality assurance practices (e.g., duplicate samples, certified reference materials).

- Define corrective actions for out-of-spec results.

Record Keeping

- Specify duration and format for retaining test records.

Advanced Oxygen Measurement for Industry

Our TRACED Oxygen Analyzer is tailored for rigorous industrial applications, offering precise and continuous oxygen monitoring. The sturdy mild steel build and electric power supply ensure longevity and uninterrupted operation in challenging settings. This analyzer helps industries maintain quality control and meets regulatory standards for safety and product excellence.

Reliable Design, Versatile Usage

With its user-oriented design, the TRACED Oxygen Analyzer can be seamlessly integrated into diverse industrial infrastructures. Its compatibility with a 240 Volt electrical system makes installation straightforward. The grey mild steel construction provides resilience against environmental stress, ensuring that your operations are protected and efficient.

FAQs of TRACED OXYGEN ANALYZER:

Q: How does the TRACED Oxygen Analyzer function in an industrial setting?

A: The analyzer operates using an electric power supply of 240 Volts, enabling continuous and accurate measurement of oxygen levels in industrial environments. Its sensors detect oxygen concentrations, providing real-time data to enhance safety and process control.Q: What are the main applications of the TRACED Oxygen Analyzer?

A: This analyzer is widely used in industrial sectors needing precise oxygen monitoring, such as chemical processing, metallurgy, and manufacturing, where control of oxygen levels is critical for safety and product quality.Q: When should I use a TRACED Oxygen Analyzer in my workflow?

A: It is recommended to use the analyzer during operations where accurate oxygen level monitoring is vital, such as process control, quality assurance, or safety checks, to ensure optimal performance and compliance with regulations.Q: Where is the TRACED Oxygen Analyzer typically installed?

A: These analyzers are generally installed in process lines, production plants, or laboratory spaces within industrial facilities where monitoring environmental oxygen levels is essential to safety and efficiency.Q: What is the process for installing the TRACED Oxygen Analyzer?

A: Installation involves mounting the device at a suitable location in your industrial setup, connecting it to a 240 Volt electric supply, and calibrating the sensors according to manufacturer guidelines to ensure precise readings.Q: How does using this analyzer benefit my industrial operations?

A: By providing accurate oxygen level measurements, it helps prevent hazards, ensures product consistency, and supports compliance with industry standards, ultimately improving operational reliability and safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gas Analysers Category

SO2 Gas Analyzer

Price 328500 INR / Pack

Minimum Order Quantity : 1 Pack

Power Supply : Electric

Usage : Industrial

Humidity : < 85%RH

Weight : 2.5 Kilograms (kg)

Portable Biogas Analyzer with Printer

Price 248500 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : Lithium Rechargeable Battery

Usage : Monitoring and Analyzing Systems

Portable Stack Gas Analyzer

Price 62500 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : Electric

Usage : Industrial

Humidity : < 85%RH

Weight : 1.5 Kilograms (kg)

Confined Space Oxygen Gas Leak Monitor

Price 30000 INR / Number

Minimum Order Quantity : 1 Number

Power Supply : Electric

Usage : Industrial

Humidity : < 85%RH

Weight : 300 Grams (g)

Send Inquiry

Send Inquiry