- Dew Point Meters

- Gas Analysers

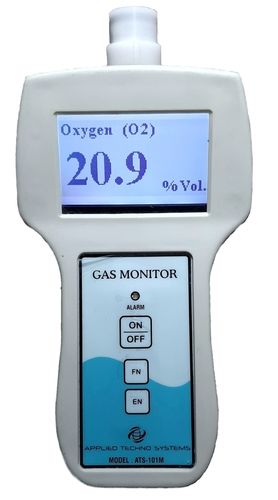

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

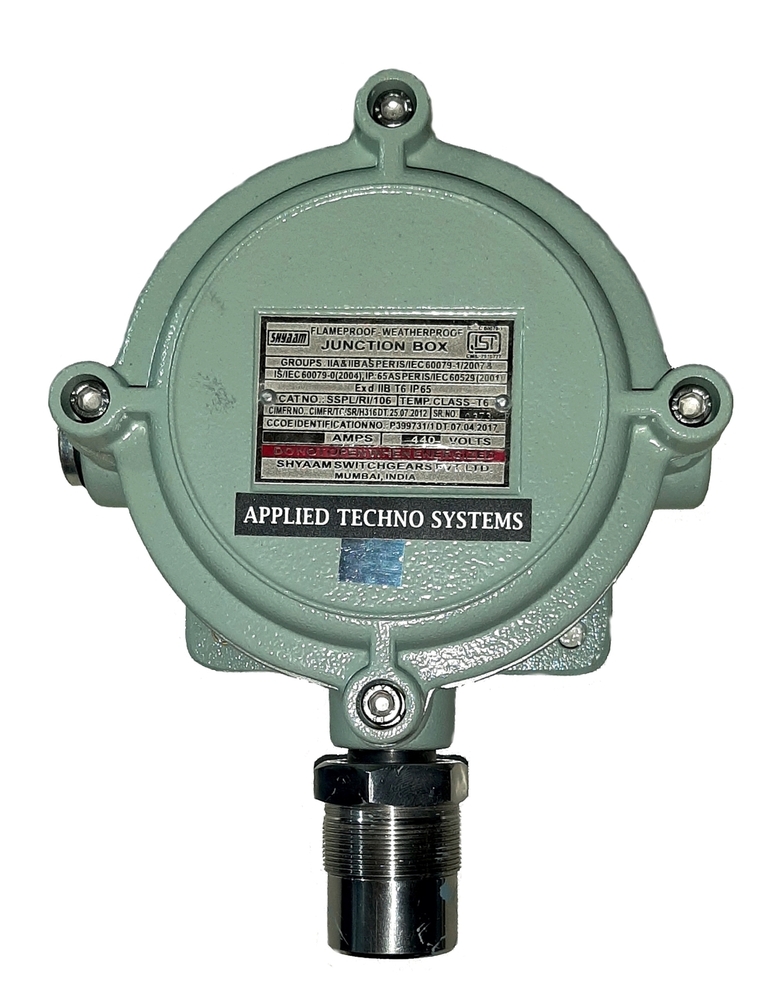

- Gas Sensor Transmitter

CO Gas Transmitter

Price 26500 INR/ Unit

CO Gas Transmitter Specification

- Power Supply

- 24V DC

- Features

- High sensitivity, Real-time monitoring, Long service life, Fault detection

- Display Type

- LCD digital display

- Application

- Detection and monitoring of Carbon Monoxide (CO) gas in industrial and commercial environments

- Mounting Type

- Wall-mounted

- Port Size

- 1/4 NPT

- Resolution

- 1 ppm

- Humidity

- 15% ~ 95% RH (non-condensing)

- Automation Grade

- Automatic

- Interface Type

- 4-20mA output, RS485 Modbus

- Equipment Type

- CO Gas Transmitter

- Usage

- Continuous CO monitoring

- Control Mode

- Automatic/Manual

- Enclosure Rating

- IP65

- Calibration Interval

- 12 months recommended

- Status Indicators

- LED (Power, Alarm, Fault)

- Dimensions

- 170 x 140 x 70 mm

- Alarm Output

- Relay (Normally open or closed)

- Sensor Type

- Electrochemical sensor

- Material

- ABS plastic housing

About CO Gas Transmitter

- Refineries

- Gas turbines

- Drilling and production platforms

- Chemical plants

- Fuel loading facilities

- Compressor stations

- Oil well logging

- Wastewater treatment facilities

- LNG/LPG processing and

- storage facilities

- Transportation facilities

Advanced Detection Technology

The transmitter utilizes an electrochemical sensor, renowned for its fast response (30 seconds) and high accuracy (3% F.S.), to ensure precise CO detection. Coupled with an LCD digital display and advanced fault diagnostics, the device allows for seamless and accurate real-time monitoring in demanding industries.

Robust Construction & Easy Installation

Encased in IP65-rated ABS plastic housing, the transmitter is well-equipped to handle dusty or moist conditions. Compact dimensions and a wall-mount design support straightforward installation in both industrial and commercial locations, ensuring versatile usage across different applications.

Versatile Control and Alarming

With both automatic and manual control modes, along with relay outputs (NO/NC), the transmitter integrates smoothly with existing safety systems for timely alerting of CO hazards. Visual status LEDs provide immediate feedback on system status, contributing to rapid and effective decision-making for personnel safety.

FAQ's of CO Gas Transmitter:

Q: How is the CO Gas Transmitter installed and where should it be mounted?

A: The CO Gas Transmitter is designed for easy wall-mounting using its compact ABS enclosure. Install the unit in areas where carbon monoxide accumulation is likely, such as industrial workspaces or commercial garages, ensuring it is placed at breathing zone height and away from direct exhaust sources.Q: What is the recommended process for calibrating the CO Gas Transmitter?

A: Calibration is recommended every 12 months to maintain accuracy. Use certified span and zero CO gases, and follow the manufacturer's calibration procedure. This process ensures the electrochemical sensor delivers reliable and precise readings throughout its service life.Q: What are the main benefits of using this CO Gas Transmitter for continuous CO monitoring?

A: Key benefits include high sensitivity and real-time monitoring of CO levels, enhanced safety through rapid response alarm relays, and intuitive status indicators. Its robust design ensures longevity, and multiple output interfaces (4-20mA, RS485 Modbus) enable smooth integration with control and alert systems.Q: How does the alarm output of the device operate during a CO gas detection event?

A: When the transmitter detects CO levels surpassing set thresholds, it activates the relay alarm output (normally open or closed). This can trigger external alarms, ventilation systems, or other safety protocols to mitigate CO exposure risks immediately.Q: What environmental conditions can this transmitter handle during usage?

A: Designed for reliability, the transmitter operates within -20C to +50C, at 15-95% RH (non-condensing), and standard atmospheric pressure. Its IP65 enclosure protects it from dust and water, making it suitable for harsh or humid industrial environments.Q: What interfaces are available for connecting the transmitter to control systems?

A: The CO Gas Transmitter provides both a 4-20mA analog output and RS485 Modbus digital interface, allowing flexible integration with modern building management, safety, or automation systems for remote monitoring and control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Detector Category

SF6 Gas Leak Detector

Price 138500 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Gas Leak Detection

Features : Auto zeroing, audible and visual alarms, data logging

Display Type : Digital LCD

Humidity : 95% RH

Industrial Hydrogen Gas Leak Detector

Price 80000.0 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Features : High Quality

Display Type : Digital

Humidity : < 85% RH

Portable Hydrogen Gas Leak Meter

Price 32500.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Detection Of Hydrogen

Features : High Quality

Display Type : Digital

Humidity : 95% RH

Sulfur Dioxide SO2 Gas Detector

Price 72800 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Monitoring and Detection Systems

Display Type : Digital

Humidity : < 85%RH

Send Inquiry

Send Inquiry