- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

Continuous SO2 Monitoring System

Price 380500.00 INR/ Set

Continuous SO2 Monitoring System Specification

- Temperature

- 15 Celsius (oC)

- Display Type

- Digital

- Power Supply

- Electric

- Features

- High Quality

- Usage

- Industrial

- Humidity

- < 85%RH

- Accuracy

- +2 %

Continuous SO2 Monitoring System Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Mumbai

- Supply Ability

- 20 Sets Per Week

- Delivery Time

- 2-3 Week

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Normal Packing With Thermocol

- Main Domestic Market

- All India

About Continuous SO2 Monitoring System

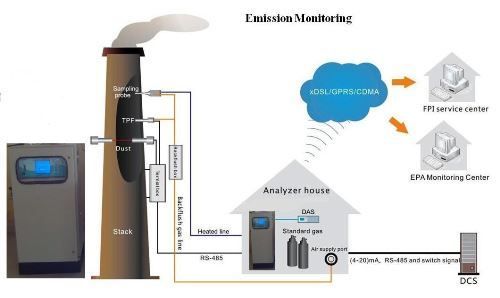

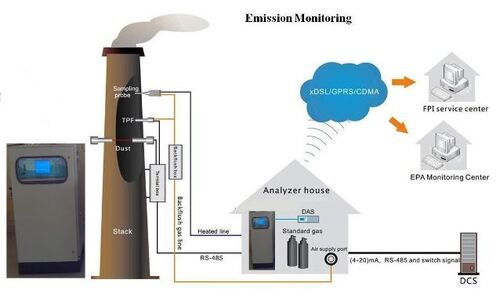

Continuous SO2 Monitoring System Model ATS-208A

We have gained tremendous success in the international market for offering superior quality Continuous SO2 Monitoring System. This analyzer is manufactured by utilizing quality approved components and cutting-edge technology in sync with international norms. Offered analyzer is widely used for monitoring the source emissions for harmful gaseous from furnaces, boilers, incinerators and other industrial processes. Our clients can purchase this Continuous SO2 Gas Analyzer from us in standard as well as customized options.

Features:

- Low energy consumption

- Durable finish standards

- Longer service life

- Compact design

Description :-

Model ATS- 208A Emission Analyzer continuously monitors the concentration of gases ranging from 100%V/V down to PPM level. Feature includes a duel wavelength sensor, Remote Sampling, Graphics LCD Display, adjustable level relay output for alarm and 4-20mA output for control purpose and minimal maintenance.

The Sensor and Electronic component are housed in tough aluminium housing.

Specification :

| Principle | Electrochemical, TCD (Thermal Conductivity) , NDIR (Non Dispersive Infrared ), Zirconium and Paramagnetic |

| Range | %V/V, % LEL, PPM, Mg/M3 |

| Resolution | 0.1 Unit or 1 Unit (Application based) |

| Sampling Method | Auto Suction |

| Gas Sampling Probe | Dia 8mm SS 316 |

| Display | 320 X 264 Graphic LCD |

| Alarm | Relay Contact NO+NC |

| Anolog Out Put | 4-20mA |

| Digital Out Put | RS 232, RS 485 and Modbus Comminication Protocol |

| Power Source | 230VAC |

| Accuracy | +/2% |

| Response Time | <5 Second |

| Data Storage | 5000 or 10000 |

| Computer Interface | RS 232, USB, RS485 |

| Sensor Life | 2-3 Years |

| Environmental |

|

| Temperature | 15degree Celsius |

| Humidity | < 85%RH |

| Atmosphere Pressure | 86- 106Kpa |

| Dimension in mm | 430 (W) X 150(H) X 250(D) |

| Weight | 2.5 KG |

| Warranty | One Year |

FAQs of Continuous SO2 Monitoring System:

What is consistent air checking framework?

A nonstop emanation checking framework (CEMS) is the all out hardware fundamental for the assurance of a gas or particulate matter fixation or discharge rate utilizing contamination analyzer estimations and a change condition, chart, or PC program to deliver brings about units of the material outflow

Which method is the most appropriate for persistent checking of carbon dioxide?

CEMS. The most well-known strategy for emanations checking, a consistent discharges observing framework (CEMS) is an instrument that is prepared to do constantly estimating genuine outflows from a fixed source progressively.

What is the significance of CEMS?

It is a significant instrument for contamination observing, control and revealing. The framework guarantees information precision, higher observing recurrence, negligible manual mediation, firm administrative checking and better straightforwardness to fortify the contamination control system.

Advanced SO2 Detection for Industrial Needs

This monitoring system is tailored for industrial applications where precise sulfur dioxide measurement is essential. It assures reliable operation across varying conditions, providing consistent data output for timely decision-making. High-quality construction and a user-friendly digital display contribute to safer, cleaner, and compliant facilities.

Reliable Performance in Challenging Environments

Engineered for resilience, the SO2 Monitoring System maintains high accuracy at temperatures of 15C and humidity levels under 85%RH. Its robust design ensures stability and minimal maintenance, making it a dependable choice for long-term operation in demanding industrial locations.

FAQs of Continuous SO2 Monitoring System:

Q: How does the Continuous SO2 Monitoring System operate in industrial settings?

A: The system utilizes advanced sensors and digital technology to continuously measure SO2 concentrations in industrial environments. Data is displayed in real-time, facilitating immediate responses to emission levels.Q: What benefits does a digital display provide for SO2 monitoring?

A: A digital display offers clear, instantaneous readings, minimizing user errors and enabling quick data interpretation for effective SO2 management and regulatory compliance.Q: When should this monitoring system be installed in an industrial facility?

A: It is advisable to install the system prior to the commencement of industrial processes involving SO2 emissions. Continuous monitoring from the outset supports early detection and prevention of hazardous conditions.Q: Where can the Continuous SO2 Monitoring System be used?

A: It is suitable for installation in any industrial facility in India where SO2 emissions are present or regulated, including chemical plants, refineries, and manufacturing units.Q: What is the process for maintaining the accuracy of the monitoring system?

A: Routine calibration and scheduled maintenance are recommended to preserve the systems 2% accuracy. Regular checks ensure reliable performance and compliance with safety standards.Q: How does the system benefit exporters, importers, manufacturers, and service providers in India?

A: By enabling continuous SO2 monitoring, the system helps businesses adhere to international emission standards, enhance workplace safety, and demonstrate environmental responsibility, supporting both domestic and global operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Online Gas stack Gas Analyzer

Price 850000 INR / Set

Minimum Order Quantity : 1 , , Unit

Usage : Industrial

Power Supply : 230 V

Online Continuous Emissions Monitoring Systems (OCEMS)

Price 725500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Continuous Emission Monitoring

Power Supply : 230 V AC 50Hz

Accuracy : +2 %

Display Type : Digital

Continuous Emission Monitoring System

Price 250000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Accuracy : +2 %

Display Type : Digital

Stack emissions

Price 725000 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Power Supply : Electric

Accuracy : +2 %

Display Type : Digital

Send Inquiry

Send Inquiry