- Dew Point Meters

- Gas Analysers

- Portable Gas Detector

- Moisture And Dew Point Analyzer

- Dust/Opacity Monitor

- Gas Monitoring Systems

- Gas Leak Detectors

- Gas Transmitters

- VOC Leak Detector

- Air Quality Monitoring System

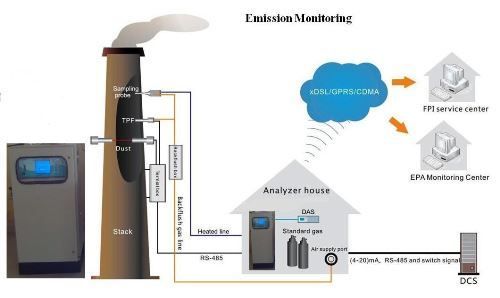

- Online Continuous Emission Monitoring System-OCEMS

- Dew Point Monitors

- Gas Detector

- Opacity Monitor

- Portable Flue Gas Analyzer

- Online SOX & NOX Gas Analyzer

- Methane Gas Leak Detector

- Hydrogen Purity Analyzer

- Gas Purity Analyzer

- Effluent Monitoring Systems

- Producer Gas Analyzer

- Gas Detector Calibration Service

- Portable Gas Monitors

- Gas Sensor Transmitter

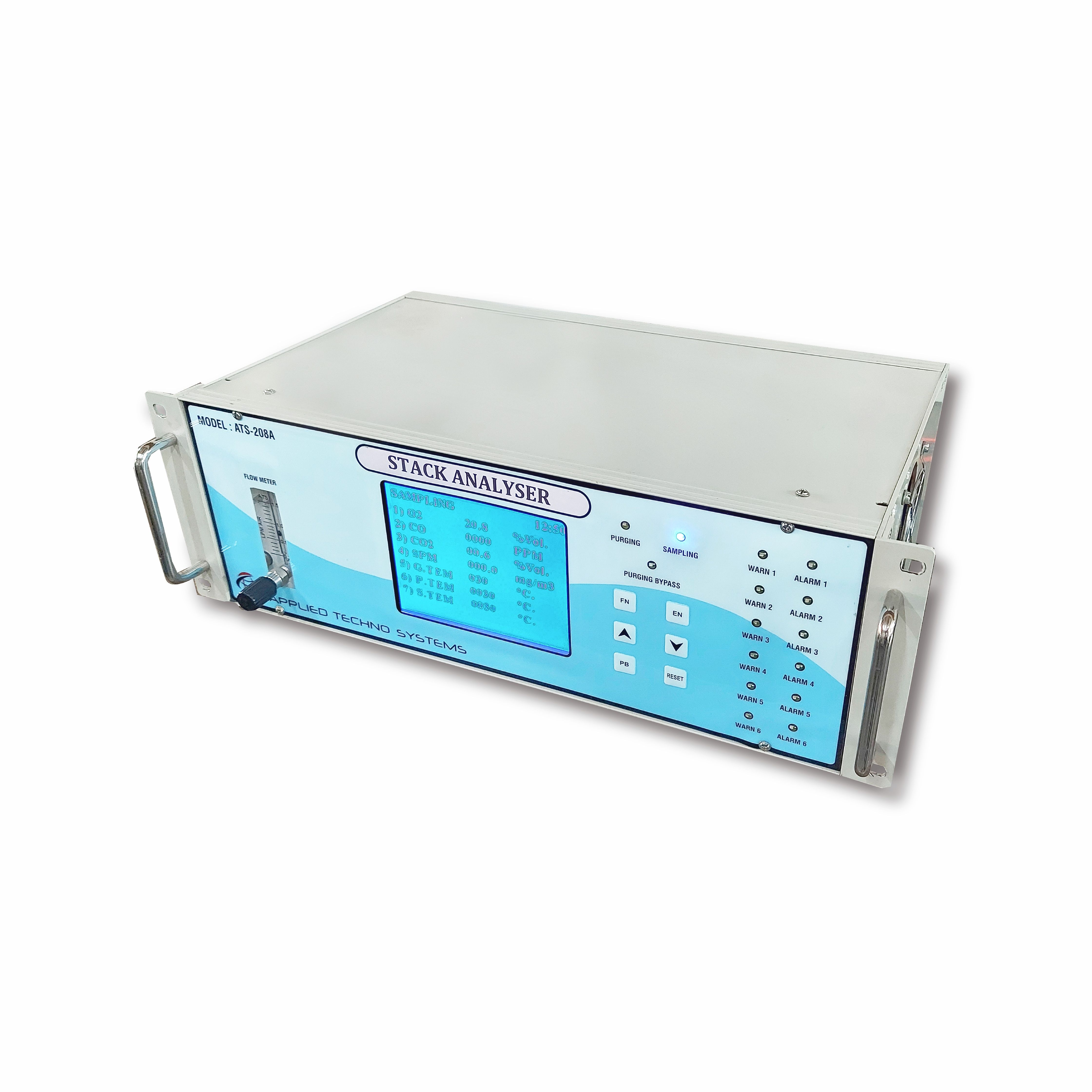

Stack emissions

Price 725000 INR/ Number

Stack emissions Specification

- Features

- High Quality

- Usage

- Industrial

- Dimension (L*W*H)

- 430 x 260 x 150 Millimeter (mm)

- Display Type

- Digital

- Color

- Grey

- Voltage

- 240 Volt (v)

- Temperature

- -20 to +50 Celsius (oC)

- Accuracy

- +2 %

- Humidity

- 85%RH

- Power Supply

- Electric

- Material

- Aluminium

About Stack emissions

Measurement Ranges

- SOx (SO): Typical measurement ranges are from 0200 ppm to 05,000 ppm, depending on regulatory requirements and process conditions.

- NOx (NO, NO): Measurement ranges often vary from 0100 ppm to 01,000 ppm, adjustable based on the expected concentration in the exhaust.

- CO: CO is often measured in percentage values, typically 020%, although some applications may require lower or higher ranges (e.g., 050%).

Detection Methods

- SOx: Commonly measured using UV fluorescence, non-dispersive infrared (NDIR), or electrochemical sensors.

- NOx: NOx levels are measured using chemiluminescence, NDIR, or electrochemical detection.

- CO: Primarily monitored using NDIR sensors or infrared gas analyzers.

- SOx and NOx: Generally, response times range from 30 seconds to 2 minutes for real-time monitoring.

- CO: Typically has response times around 15 to 30 seconds.

Accuracy and Precision

- SOx: Typically 1% of full scale.

- NOx: Around 2% of full scale.

- CO: 1% of the measurement range.

Resolution

- SOx: Typically around 1 ppm.

- NOx: 0.11 ppm, depending on sensor sensitivity.

- CO: Typically 0.01% for higher precision.

Operating Temperature

- Generally from -20C to +50C for standard stack monitoring systems, but some applications may require operation in higher temperature ranges (up to 300C with cooling or sample conditioning).

Sample Conditioning System

- Includes filters, condensers, and pumps to prepare samples at high temperatures and humidity, especially in combustion environments.

Data Output and Communication

- Output Signals: 420 mA, RS-485, Modbus, Ethernet for integration with SCADA or other data acquisition systems.

- Data Logging: Systems should have onboard memory and support for data logging, as well as remote data access options.

Compliance Standards

- Should meet standards such as U.S. EPA 40 CFR Part 60, European EN 14181, and local environmental regulations for emissions.

Calibration Requirements

- Automated or manual calibration with span and zero gases (e.g., nitrogen for zeroing, standard reference gases for span calibration). Calibration intervals depend on regulation and analyzer type.

These specifications ensure that SOx, NOx, and CO monitoring systems meet the accuracy, reliability, and regulatory compliance required for effective emissions monitoring in industrial applications.

Precision Performance in Harsh Conditions

This stack emission monitor stands out for its high accuracy and dependable performance, even in environments with up to 85% humidity. Engineered from high-quality aluminum and fitted with a digital display, it delivers real-time data, making it perfect for industrial usage where precision and reliability are paramount.

Comprehensive Industrial Solutions

As a multifaceted providerexporter, importer, manufacturer, service provider, and supplierwe ensure seamless delivery and installation across India. Our emission monitors are designed to adapt to various industrial contexts, catering to compliance, safety, and operational efficiency requirements.

FAQs of Stack emissions:

Q: How is the stack emissions monitor installed at industrial sites?

A: Installation is straightforward, thanks to its compact dimensions (430 x 260 x 150 mm) and electric power supply. The device is mounted at emission sources, connected to a standard 240V outlet, and calibrated using the digital interface for accurate readings.Q: What benefits does this device offer for emission monitoring?

A: Users benefit from high accuracy (+2%), reliable performance in high humidity (up to 85% RH), and simple digital operation. The durable aluminum body ensures longevity and resistance to harsh industrial conditions, supporting regulatory compliance and operational optimization.Q: When should routine maintenance be performed on the monitor?

A: Routine maintenance is recommended at regular intervals, typically every six months, or as specified by industrial protocols. This ensures sustained accuracy and effective monitoring performance in challenging environments.Q: Where can this stack emission monitor be used in India?

A: This device is suitable for all types of industrial facilities across India and is supplied by us nationwide. Its robust build and wide operating temperature range make it ideal for diverse regions and climates.Q: What is the process for exporting or importing the stack emissions monitor?

A: As an experienced exporter and importer, we manage all export/import documentation, customs procedures, and logistics, ensuring swift, compliant delivery to clients within and outside India.Q: How does humidity affect the measurement accuracy?

A: The monitor is designed to function accurately in high humidity environments (up to 85% RH), maintaining its +2% measurement precision even under these challenging conditions.Q: Can the device display real-time emission readings?

A: Yes, the digital display provides immediate and continuous emission data, allowing operators to monitor and respond to changes in emission levels effectively during industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Online Continuous Emission Monitoring System-OCEMS Category

Online Continuous Emission Monitoring Systems (OCEMS)

Price 586500.00 INR / Set

Minimum Order Quantity : 1 Set

Features : High Quality

Display Type : Digital

Usage : Continues Emission Monitoring for stack

Power Supply : 230 VAC

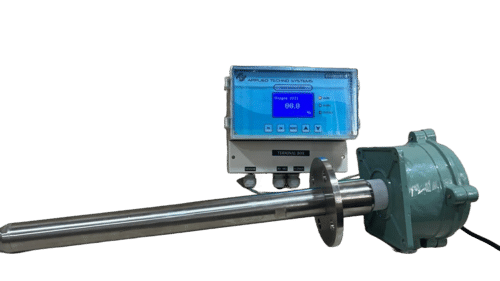

insitu zirconia based oxygen analyzer

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : Good Quality

Display Type : Digital

Usage : Industrial

Power Supply : Electric

Online Continuous Emissions Monitoring Systems (OCEMS)

Price 725500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Quality

Display Type : Digital

Usage : Continuous Emission Monitoring

Power Supply : 230 V AC 50Hz

Continuous Emissions Monitoring Systems (SPM)

Price 120000 INR / Number

Minimum Order Quantity : 1 Number

Features : High Quality

Display Type : Digital

Usage : Industrial

Power Supply : Electric

Send Inquiry

Send Inquiry